Multi-orifice pencil-style fuel injectors

A fuel injector and nozzle hole technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve the problem of increasing the impact force of the needle valve on the injector seat surface, increasing CO and HC emissions, and being difficult to achieve green environmental protection. and other problems, to achieve the effect of eliminating the phenomenon of oil nozzle stuck, improving the sealing performance and improving the heating condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

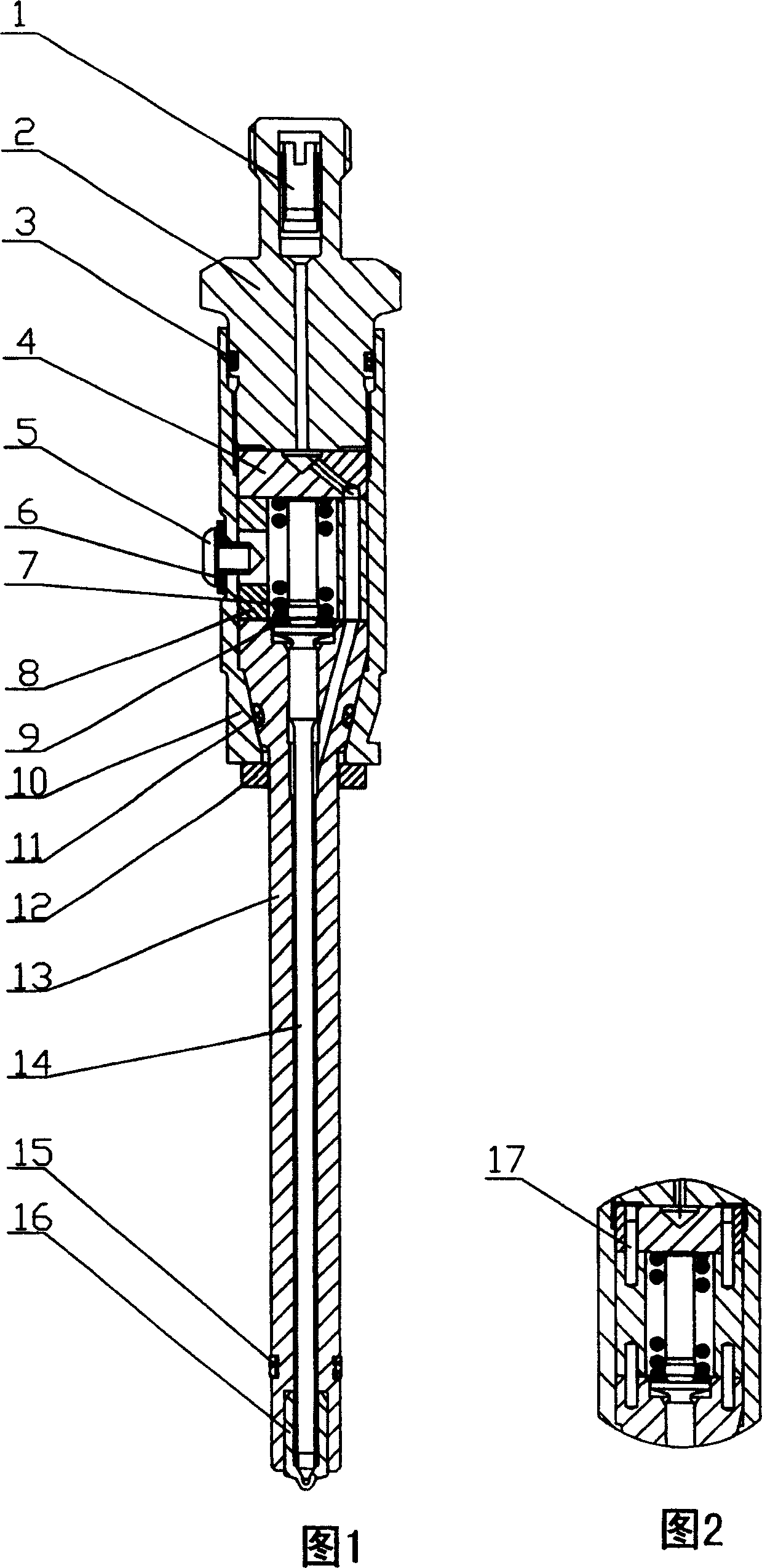

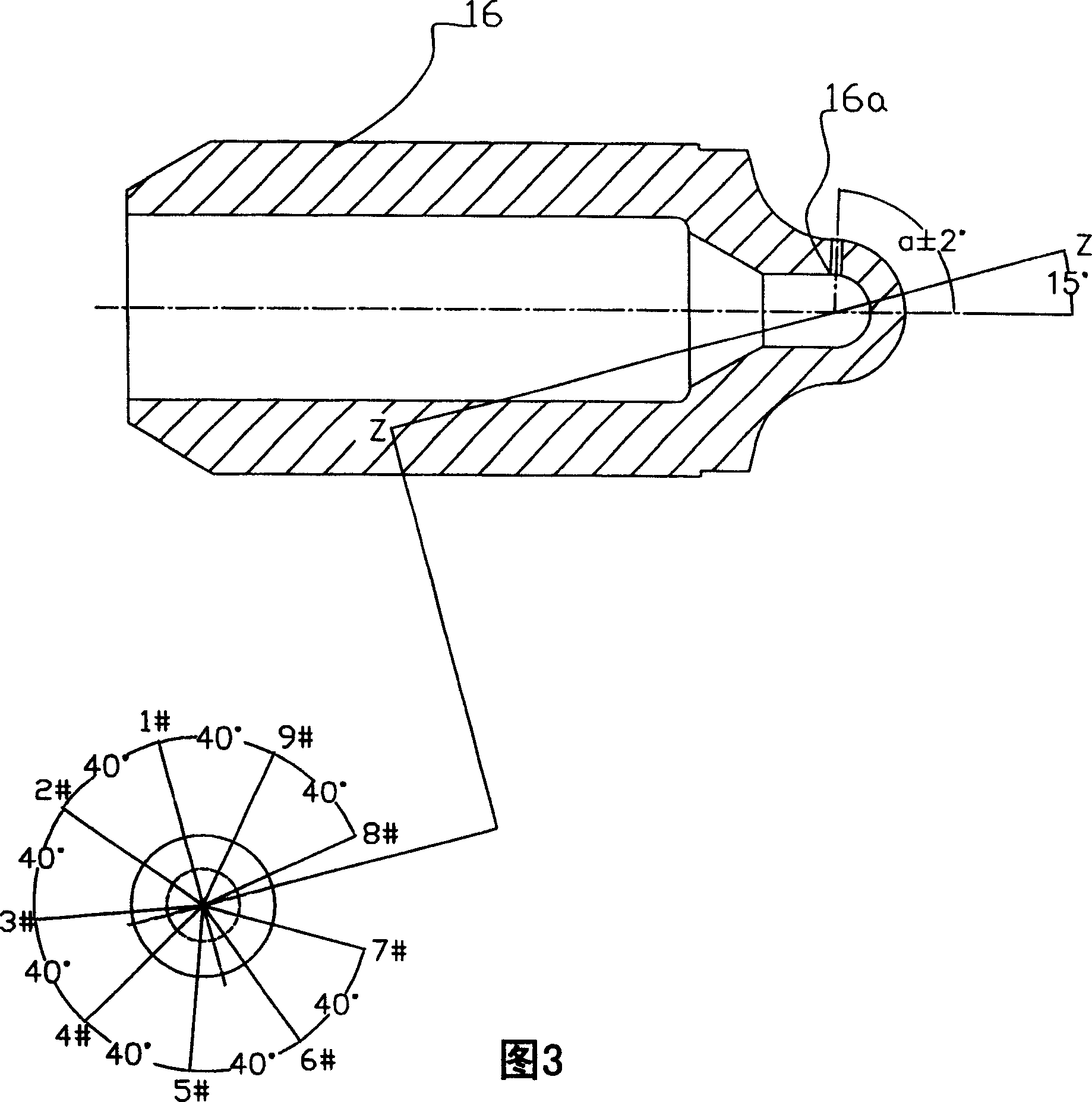

[0015] Structure of the present invention is shown in accompanying drawing 1~3.

[0016] Fig. 1 is a schematic diagram of the longitudinal section structure of the present invention; as shown in Fig. 1, the multi-nozzle pencil-type fuel injector includes a fuel injector body 13 with an inner cavity, an oil inlet joint 2 pressed with a filter element 1, a needle valve 14, The fuel injection nozzle 16 and the oil inlet connector 2 are screwed into the inner circumference of the tight cap 10, and are in contact with the needle valve stopper 4. An O-ring 3 is set between the oil inlet connector 2 and the tight cap 10, for a tighter fit. The outer periphery of the front end of the fuel injector body is also sleeved with a gasket 12; the outer periphery of the rear end of the fuel injector body 13 is covered with an O-ring 11, and the rear end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com