Polyurethane solid tyre and manufacturing method thereof

A technology for solid tires and manufacturing methods, which is applied to tire parts, non-pneumatic tires, transportation and packaging, and can solve the problems of poor application effect of polyurethane solid tires, poor heat conduction and heat dissipation performance of the wheel core, and increased carcass temperature. , to achieve the effects of easy industrial production, good heat dissipation performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The manufacture of single-layer polyurethane solid tires uses polyurethane materials to be directly bonded to metal rims, specifically including the following steps and process conditions:

[0046] Step 1: Surface treatment of the metal rim

[0047] (1) Preparation of adhesive:

[0048] Take 45 parts by weight of Chemlock 218, add it to 55 parts by weight of isopropanol and ethyl acetate mixed solvent, the weight percentage of isopropanol in the mixed solvent is 50%, stir and mix evenly;

[0049] (2) Rim surface treatment process:

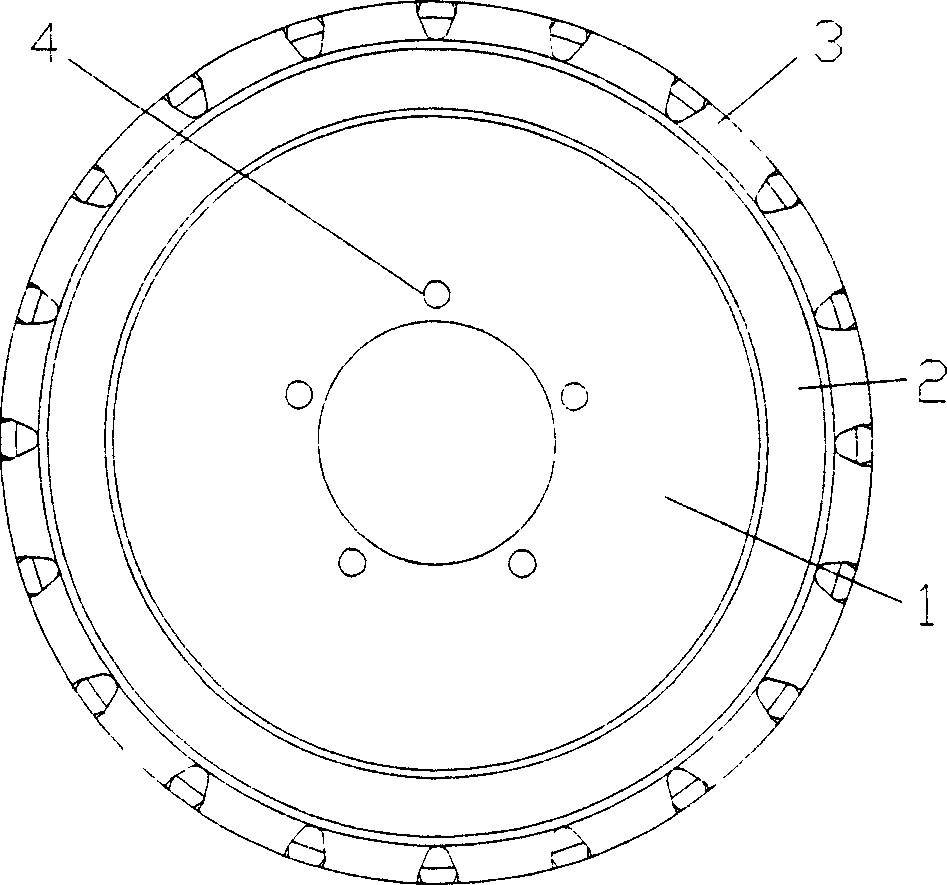

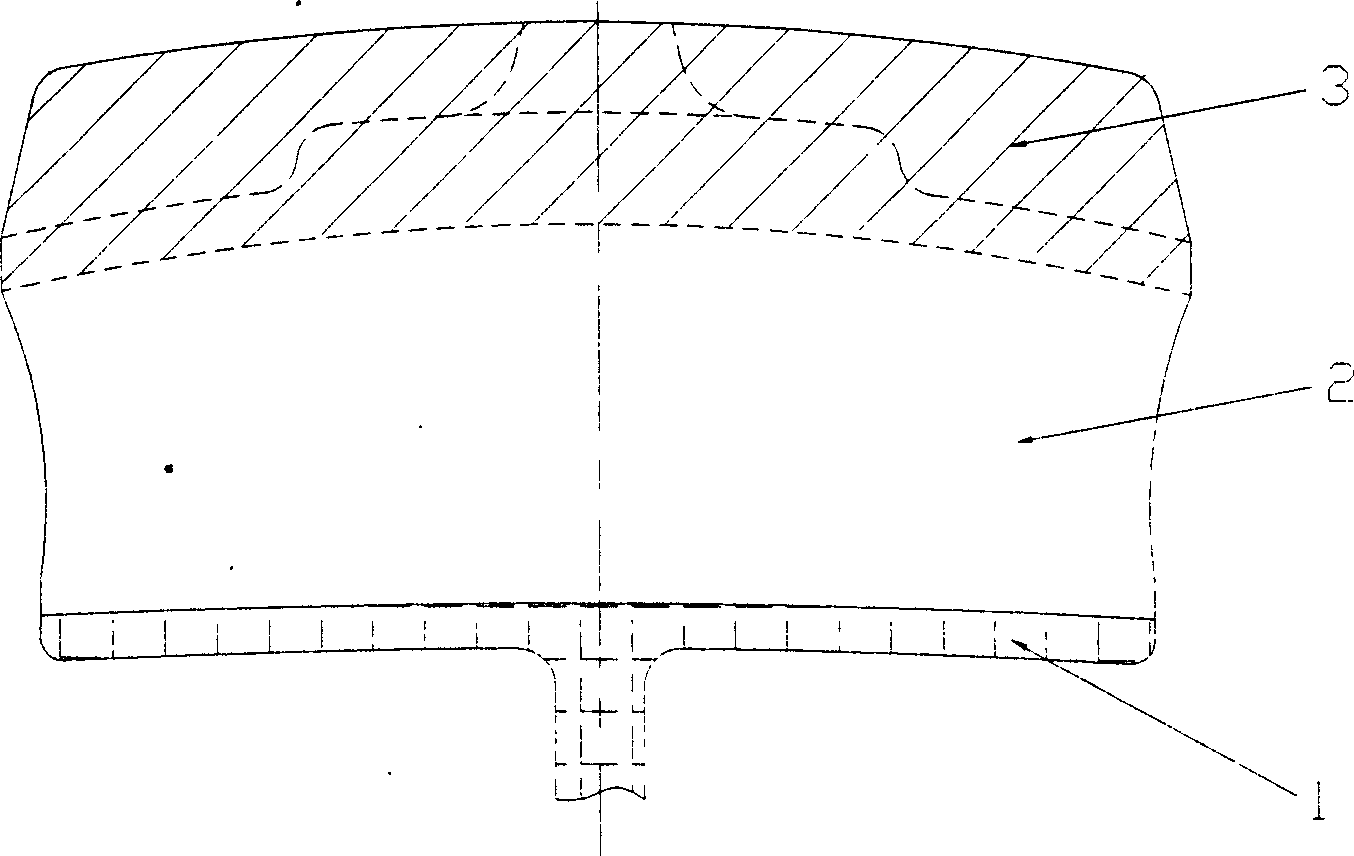

[0050] will be like figure 1 , 2Sandblast the surface of the metal rim 1 shown, then degrease and degrease the surface with ethyl acetate. After cleaning, evenly spray or brush the adhesive prepared in step 1 (1), park at room temperature for 0.5 hours, and then put it in an oven at 120°C Baking for 1 hour, ready for pouring;

[0051] Step 2: Preparation of polyurethane prepolymer system

[0052] Weigh 100 parts by weight of polytetrah...

Embodiment 2

[0064] The manufacture of single-layer polyurethane solid tires uses polyurethane materials to be directly bonded to metal rims, specifically including the following steps and process conditions:

[0065] Step 1: Surface treatment of the metal rim

[0066] (1) Preparation of adhesive:

[0067] Take 50 parts by weight of Chemlock 213, add it to 50 parts by weight of isopropanol and methyl ethyl ketone mixed solvent, the weight percentage of isopropanol in the mixed solvent is 45%, stir and mix evenly;

[0068] (2) Rim surface treatment process:

[0069] will be like figure 1 , 2 Sandblast the surface of the metal rim 1 shown, then degrease and degrease the surface with ethyl acetate. After cleaning, evenly spray or brush the adhesive prepared in step 1 (1), park at room temperature for 40 minutes, and then put it in an oven at 120°C Bake for 30 minutes, ready for pouring;

[0070] Step 2: Preparation of polyurethane prepolymer system

[0071] Weigh 40 parts by weight of p...

Embodiment 3

[0083] The manufacture of double-layer polyurethane solid tires uses polyurethane materials to be directly bonded to metal rims, specifically including the following steps and process conditions:

[0084] Step 1: Surface treatment of the metal rim

[0085] (1) Preparation of adhesive:

[0086] Take 55 parts by weight of Chemlock 219 and add it to 45 parts by weight of a mixed solvent of isopropanol and ethyl acetate. The weight percentage of isopropanol in the mixed solvent is 55%, just stir and mix evenly;

[0087] (2) Rim surface treatment process:

[0088] will be like figure 1 , 2 Sandblast the surface of the metal rim 1 shown, then degrease and degrease the surface with ethyl acetate. After cleaning, evenly spray or brush the adhesive prepared in step 1 (1), park at room temperature for 1 hour, and then put it in an oven at 120°C Bake for 45 minutes, ready for pouring;

[0089] Step 2: Preparation of polyurethane prepolymer system

[0090] (1) Weigh 100 parts by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com