Application of aliphatic polyurethane dispersion

An aliphatic polyurethane and dispersion technology, applied in the field of spindle tape, can solve the problems of low temperature resistance, short life, low elongation strength, etc., and achieve the effect of improving deformation performance, improving fabric performance, and high elongation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

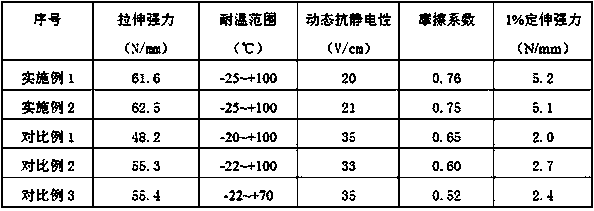

Examples

Embodiment 1

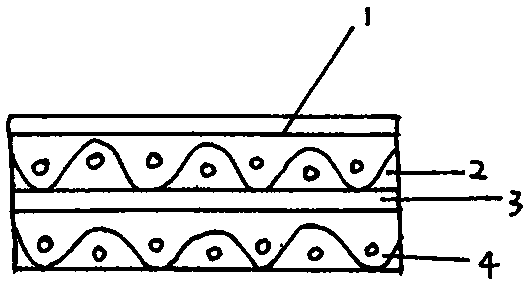

[0028] A high constant stretch spindle belt, a surface layer and a fabric layer made of modified high molecular polymers , polymer adhesive layer and fabric layer , the thickness ratio is 0.05:0.30:0.05:0.35.

[0029] The surface layer is mainly PVC-modified nitrile rubber with high acrylonitrile content, adding reinforcing agent, anti-aging agent, vulcanizing agent, the mass ratio of nitrile rubber: PVC is 8:2, and the mass ratio of each component is: Nitrile rubber: reinforcing agent: antiaging agent: vulcanizing agent = 100:32:2:2; the content of acrylic acid in the nitrile rubber with high acrylic acid content is 35~40%, and it is made of modified polymer The preparation method of the surface layer is: PVC-modified nitrile rubber with high acrylonitrile content, silicate reinforcing agent, amine and phenolic anti-aging agent anti-aging agent, sulfur-containing organic matter or peroxide vulcanizing agent, in order Add to internal mixer and knead for 5~6min.

[0030] T...

Embodiment 2

[0034] A high constant stretch spindle belt, the surface layer made of modified high molecular polymer, the treated fabric layer , polymer adhesive layer and treated fabric layer , the thickness ratio is 0.06:0.32:0.06:0.31.

[0035] The surface layer is mainly PVC-modified nitrile rubber with high acrylonitrile content, adding reinforcing agent, anti-aging agent, vulcanizing agent, the mass ratio of nitrile rubber: PVC is 8:2, and the mass ratio of each component is: Nitrile rubber: reinforcing agent: anti-aging agent: vulcanizing agent = 100:32:2:2; the content of acrylic acid in the nitrile rubber with high acrylic acid content is 35~40%. The preparation method of the surface layer made of permanent high molecular polymer is: PVC-modified nitrile rubber with high acrylonitrile content, silicate reinforcing agent, amine and phenol antioxidant, sulfur-containing organic compound or Add peroxide vulcanizing agent and vulcanizing agent into internal mixer one by one and kne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com