An elastic paper feed belt

A paper tape and elastic technology, applied in the field of printing and packaging machinery, can solve the problems of flexing and aging of the elastic layer on the surface, reducing the service life, and the appearance of hibiscus on the edge, so as to achieve the effect of stable friction coefficient, improved service life and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

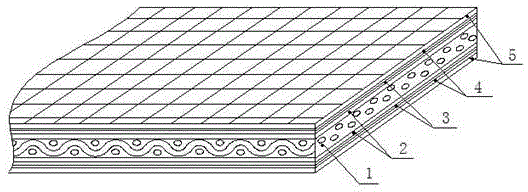

[0013] figure 1 Shown is the structural representation of the present invention.

[0014] The present invention comprises skeleton layer 1, sheet material layer 2, buffer layer 3, adhesive layer 4 and friction layer 5, and described skeleton layer 1 is the middle layer, and sheet material layer 2, buffer layer 3, adhesive Composite layer 4 and friction layer 5.

[0015] The skeleton layer 1 is composed of activated polyester or aramid fabric, which has the characteristics of good stiffness, high tensile strength, not affected by temperature and humidity, and stable size.

[0016] The material of the sheet layer 2 is TPU, TPEE or TPA, which can provide reliable and smooth tooth-shaped bonding and strong performance.

[0017] The buffer layer 3 is made of rubber with a thickness of 0.5-1.0 mm and a Shore hardness of 70-90 degrees, and plays the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com