Solution-polymerized styrene-butadiene tread rubber and mixing process thereof

A technology of solution-polymerized styrene-butadiene tire and solution-polymerized styrene-butadiene rubber is applied in the field of tire manufacturing, which can solve the problems of loss of use value and loss, and achieve excellent dynamic ozone protection ability, improved wear resistance, and good vulcanization flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

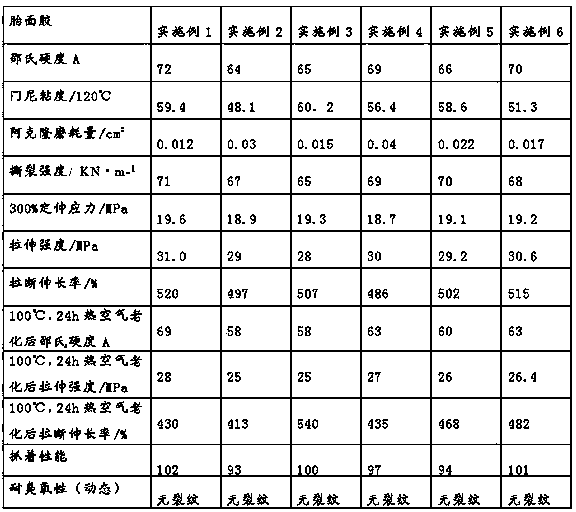

Examples

Embodiment 1

[0029] A solution-polymerized styrene-butadiene tread rubber of the present invention comprises the following components by weight:

[0030] Solution polystyrene butadiene rubber 100 Natural rubber 20

[0031] Tread rubber powder 10 Stearic acid 2

[0032] Sulfur powder 1.4 White carbon black 24

[0033] Carbon black 5 Aromatic oil 6

[0034] Zinc oxide 2 Antiaging agent 6

[0035] Pine tar 1 Accelerator 1.3

[0036] Anti-reversion agent 0.2 Binder 3.

[0037] Natural rubber is smoked film.

[0038] Carbon black is carbon black N330.

[0039] The anti-aging agent includes 30% anti-aging agent RD, 30% anti-aging agent 4020, 30% anti-aging agent 3100 and 10% type B microcrystalline wax.

[0040] The accelerator consists of 50% accelerator DM and 50% accelerator CZ.

[0041] The anti-reversion agent is PK900.

[0042] The binder is rosin and petroleum resin. The petroleum resin is a C5 petroleum resin.

[0043] The mixing process of the solution-polymerized styrene-but...

Embodiment 2

[0048] A solution-polymerized styrene-butadiene tread rubber of the present invention comprises the following components by weight:

[0049] Solution polystyrene butadiene rubber 200 Natural rubber 20

[0050] Tread rubber powder 20 Stearic acid 4

[0051] Sulfur powder 2 Silica 30

[0052] Carbon black 7 Aromatic oil 26

[0053] Zinc oxide 7 Antiaging agent 7

[0054] Pine Tar 3 Accelerator 3

[0055] Anti-reversion agent 0.9 Adhesive 5.

[0056] The natural rubber is chlorinated natural rubber.

[0057] Carbon black is carbon black N220.

[0058] The anti-aging agent includes 10% anti-aging agent RD, 20% anti-aging agent 4020, 62% anti-aging agent 3100 and 8% type B microcrystalline wax.

[0059] The accelerator consists of 90% accelerator DM and 10% accelerator CZ.

[0060] The anti-reversion agent is PK900.

[0061] The binder is rosin and petroleum resin. The petroleum resin is a C9 petroleum resin.

[0062] The mixing process of the solution-polymerized styren...

Embodiment 3

[0067] A solution-polymerized styrene-butadiene tread rubber of the present invention comprises the following components by weight:

[0068] Solution polystyrene butadiene rubber 90 Natural rubber 60

[0069] Tread rubber powder 15 Stearic acid 3

[0070] Sulfur powder 1.7 White carbon black 21

[0071] Carbon black 7 Aromatic oil 11

[0072] Zinc oxide 3 Antiaging agent 5

[0073] Pine Tar 4 Accelerator 1.5

[0074] Anti-reversion agent 0.4 Binder 3.

[0075] Natural rubber is a mixture of smoked rubber sheet, white crepe rubber sheet, granular rubber, rubber clear crepe sheet, and chlorinated natural rubber.

[0076] The carbon black is carbon black N330.

[0077] The anti-aging agent includes 20% anti-aging agent RD, 20% anti-aging agent 4020, 56% anti-aging agent 3100 and 4% type B microcrystalline wax.

[0078] The accelerator consisted of 40% accelerator DM and 60% accelerator CZ.

[0079] The anti-reversion agent is PK900.

[0080] The binder is rosin.

[0081...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com