Patents

Literature

41results about How to "Cut resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tread rubber compound with good cut and tear resistance and low dynamic heat generation

The invention discloses tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation. Natural rubber, which serves as a main material, and butadiene styrene rubber, intermediate and super wear-resisting carbon black, anti-crack resin, a multifunctional vulcanizing active agent and an anti-vulcanizing reversion agent, which serve as main auxiliary materials, areblended in an internal mixer to manufacture blended rubber, and the blended rubber is formed into a tread semi-finished product in a mode of extrusion by an extruder. The rubber has the advantages ofhigh tensile strength, high tearing strength, high stretching stress, high cutting resistant performance, low dynamic heat generation, high stability, high wear-resisting property and high anti-flexure crack performance. By using tires with the tread rubber, dumpers can be used on sharp ore road surfaces at a high speed, and the service life of the tires is long.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

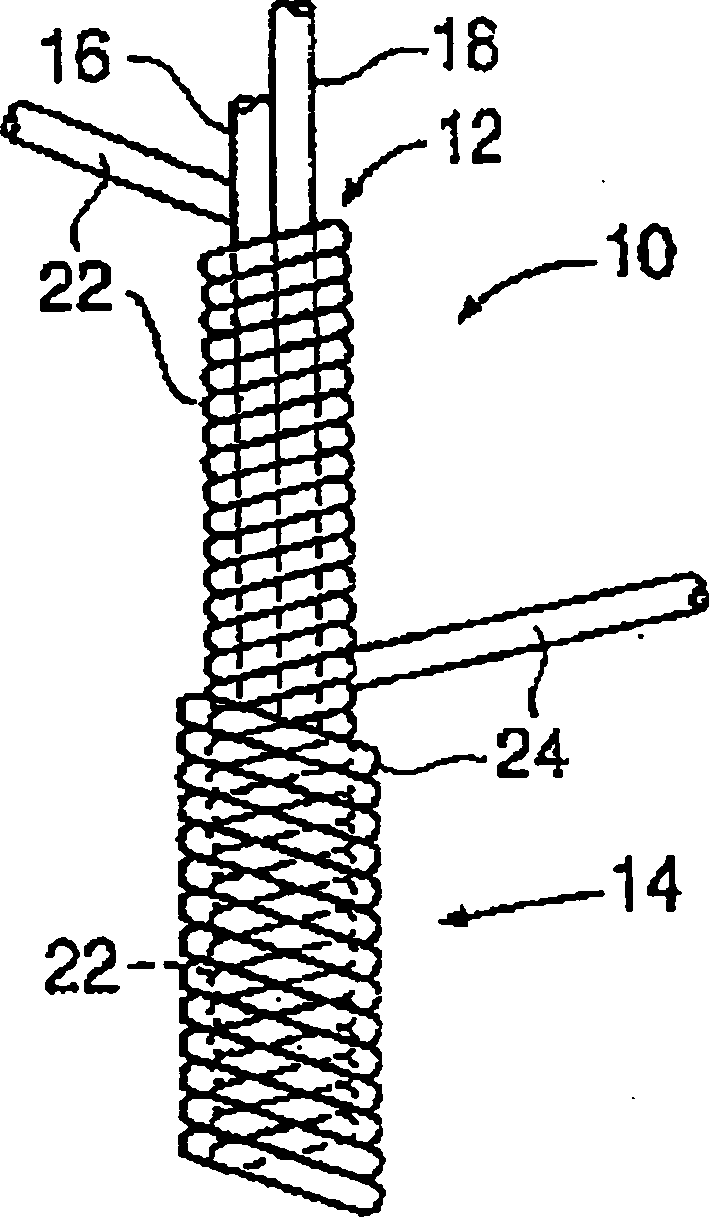

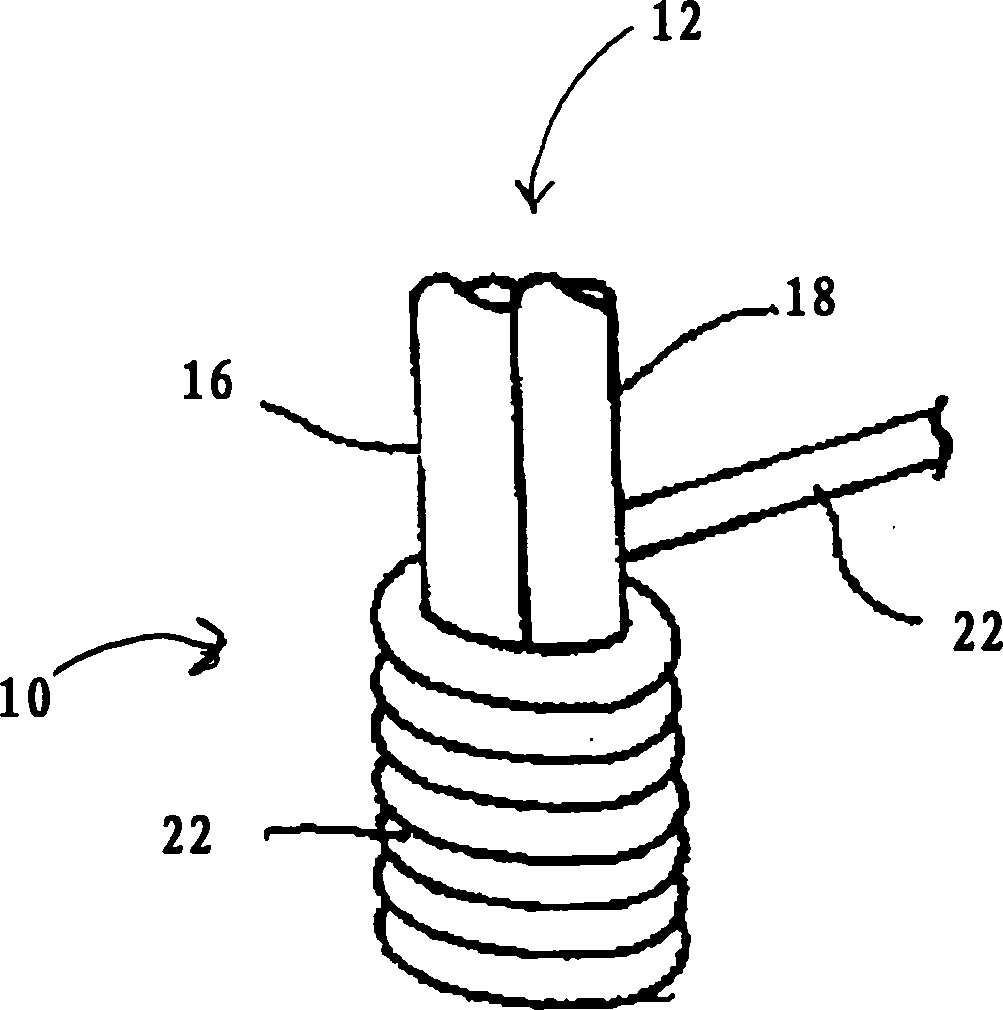

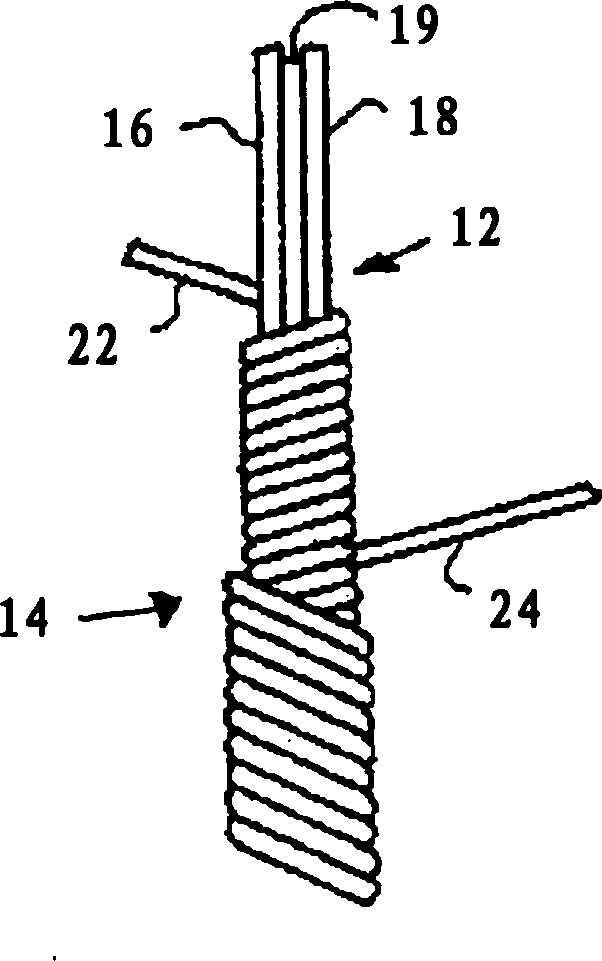

Composite fiber and articles made therefrom

A composite cut-resistant yam is provided that has no high-performance fibers present and has wire only in the core, yet is comparable in cut-resistance characteristics, the yam containing a core of at least one fiberglass strand and at least one wire strand, either parallel or twisted about one another, and at least one cover strand made from non-metallic non-high performance fiber, along with fabric made therefrom, and protective articles and garments made from the fabric.

Owner:SUPREME ELASTIC

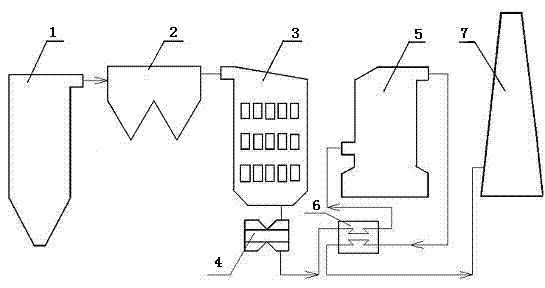

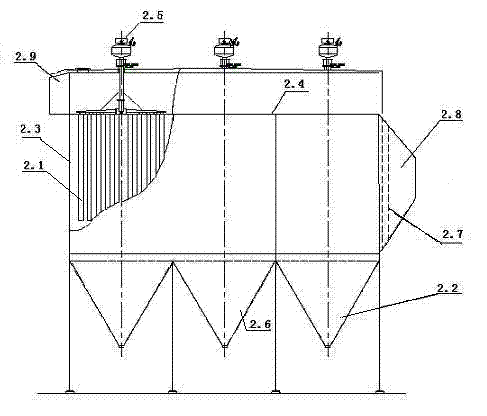

Exhaust gas dedusting, denitration and desulfuration method for thermal power plant

InactiveCN102393023AHigh strengthImprove flame retardant performanceDispersed particle filtrationCombustion processAir preheaterWhole body

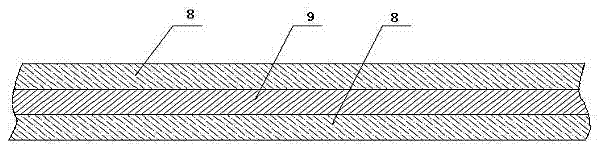

The invention relates to an exhaust gas dedusting, denitration and desulfuration method for a thermal power plant. According to the invention, after being dedusted firstly by a bag-type dust collector, high-temperature raw exhaust gas is introduced in an SCR (selective catalytic reduction) reactor for performing SCR for realizing denitration, and then, the exhaust gas subjected to denitration passes through an air preheater and a heat exchanger in sequence to be cooled to 90-100 DEG C, and then is subjected to wet desulfuration in a desulfurizer; and the exhaust gas subjected to desulfuration and discharged from the desulfurizer is heated to 100-105 DEG C by the heat exchanger and then enters a chimney to be discharged. In the bag-type dust collector, filter cloth in a filter bag has base cloth which is PBO (Poly-p-phenylenebenzobisthiazole) fiber woven cloth and has two surface layers referring to composite fibrofelts formed by cross-laying of PBO fiber nets and basalt fiber nets, the base cloth is sandwiched between the two surface layers and sewed up into a whole body, the whole body is subjected to hot rolling, singeing and heat shaping, Teflon dipping and drying to finally form high-temperature resistant filter cloth. By the adoption of the high-temperature resistant filter bag, the raw exhaust gas can be dedusted firstly at a high temperature and then is subjected to denitration, therefore, ash fouling of subsequent equipment and damages to a catalyst can be reduced, and the effects of low catalyst consumption and high denitration efficiency can be achieved; and since the catalytic reaction does not need additional heat, the effects of energy saving and emission reduction are achieved.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

Bullet, bayonet and cutting knife prevention clothes

InactiveCN102783728ABulletproofStab-resistantPersonal protection gearProtective garmentSurface layerEngineering

The invention provides a bullet, bayonet and cutting knife prevention clothes which comprises a composite coating and a bullet and bayonet prevention chip. The bullet and bayonet prevention chip is inserted into the composite coating; the composite coating comprises a camouflage surface layer and an inner layer next to skin; a layer of cutting knife prevention knitted fabric is sewn on the inner side of the camouflage surface layer; and the bayonet prevention chip is formed by overlapping at least one layer of bullet-prevention composite fabric and at least one layer of bayonet-prevention woven fabric. The product has the comprehensive functions of preventing the bullet, the bayonet and the cutting knife and greatly-improved safety performance.

Owner:SURREY HI TECH INC

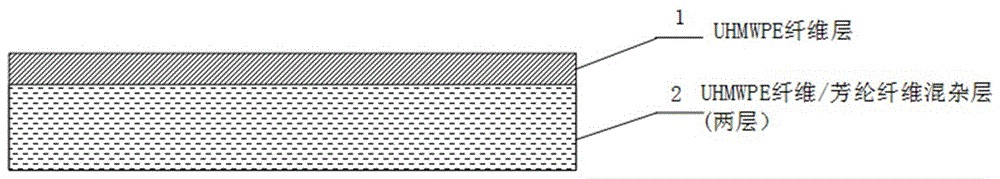

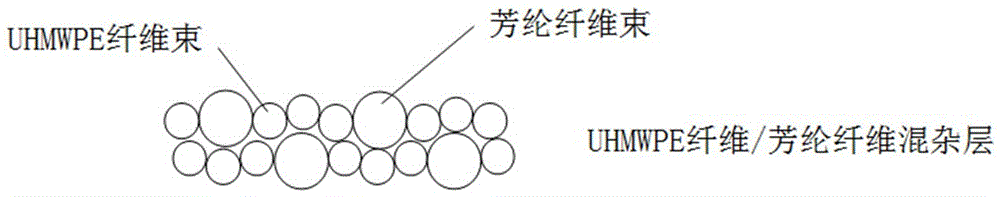

Hybrid fabric by employing ultrahigh molecular weight polyethylene fiber and aramid fiber

InactiveCN106113813ALow densityHigh specific strengthFibre typesSynthetic resin layered productsOptical radiationResin-Based Composite

The invention relates to hybrid fabric by employing ultrahigh molecular weight polyethylene fiber and aramid fiber, wherein UHMWPE fiber has the advantages of small density, high specific strength, high specific modulus, good chemical corrosion-resistant and optical radiation-resistant performances, impact resistance, wear resistance, cutting resistance, low temperature deflection resistance, high electromagnetic transmissivity, and good biological compatibility. The UHMWPE fiber is polyethylene essentially, the melting point and the vicat softening point are low, so that the fiber heat resistance performance is poor, and creep deformation is obvious. The produced hybrid fabric improves the problems of interface compatibility and obvious creep deformation of the UHMWPE fiber, can be used for a resin-based composite material, solves the problems that diameters of the UHMWPE fiber and the aramid fiber are different, a gap is easily generated between the layers of the fiber cloth when the layers are overmuch, pore quantity of the composite material is large, glue amount of the resin after filling is inuniform, and intensity is decreased. The fiber can be used for enhanced fiber of the resin-based composite material.

Owner:TONGJI UNIV

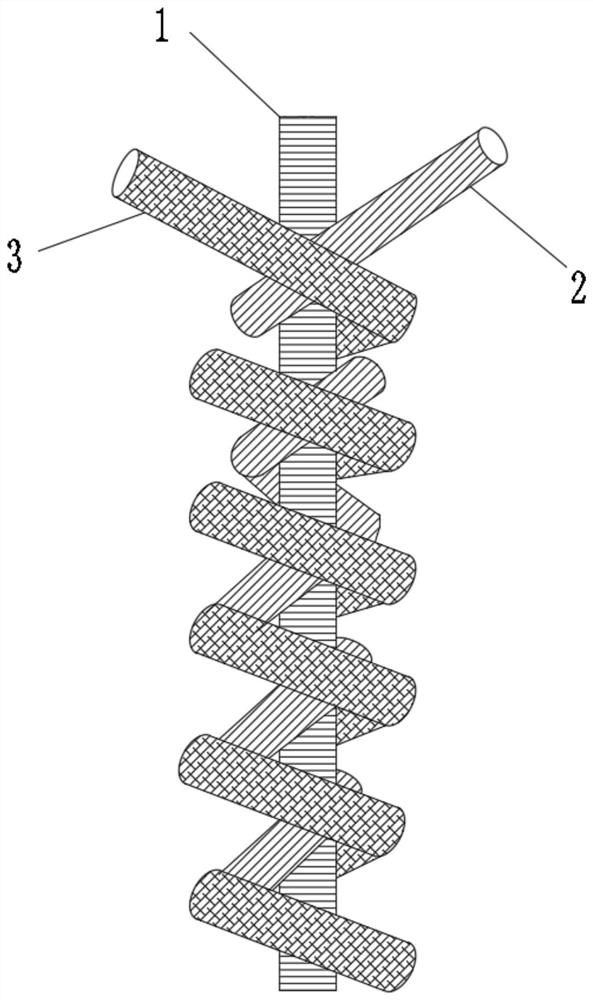

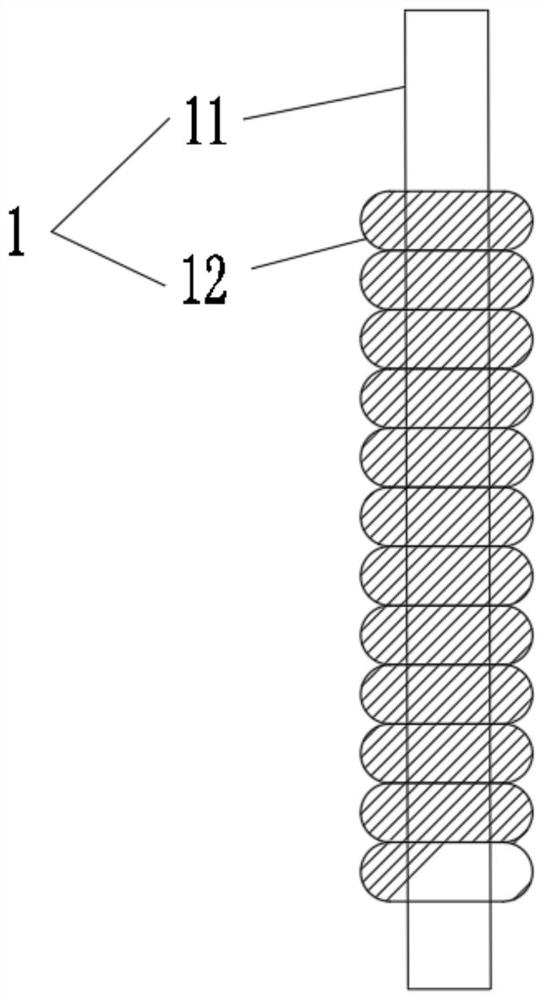

Composite fiber filament for nuclear radiation protection and production method of composite fiber filament

InactiveCN103757778AExcellent nuclear radiation protection performanceFlame retardantYarnMetal fiberNuclear radiation

The invention discloses a composite fiber filament nuclear radiation protection and a production method of composite fiber filament and relates to the technical field of nuclear radiation protection. Core knitting is performed on a knitter, and a material covered during knitting is made of carbon fiber, high density polyethylene fiber, polytetrafluoroethylene fiber, polyphenylene sulfide fiber, polyarmide fiber, polyester fiber or polyimide fiber, a coating material is made from the carbon fiber, the high density polyethylene fiber, the polytetrafluoroethylene fiber, the polyphenylene sulfide fiber, the polyarmide fiber, the polyester fiber or the polyimide fiber, and thereby the composite fiber filament with a nuclear radiation protection function is formed. The composite fiber filament comprises a metal fiber core and at least one outer knitted coating layers which are in net structures. The composite fiber filament is simple and reasonable in technology, high in yield, and beneficial to follow-up weaving for weaving the composite fiber filament into fabric via a weaving technology so as to form clothes with the nuclear radiation protection function.

Owner:扬州锦沃科技有限公司

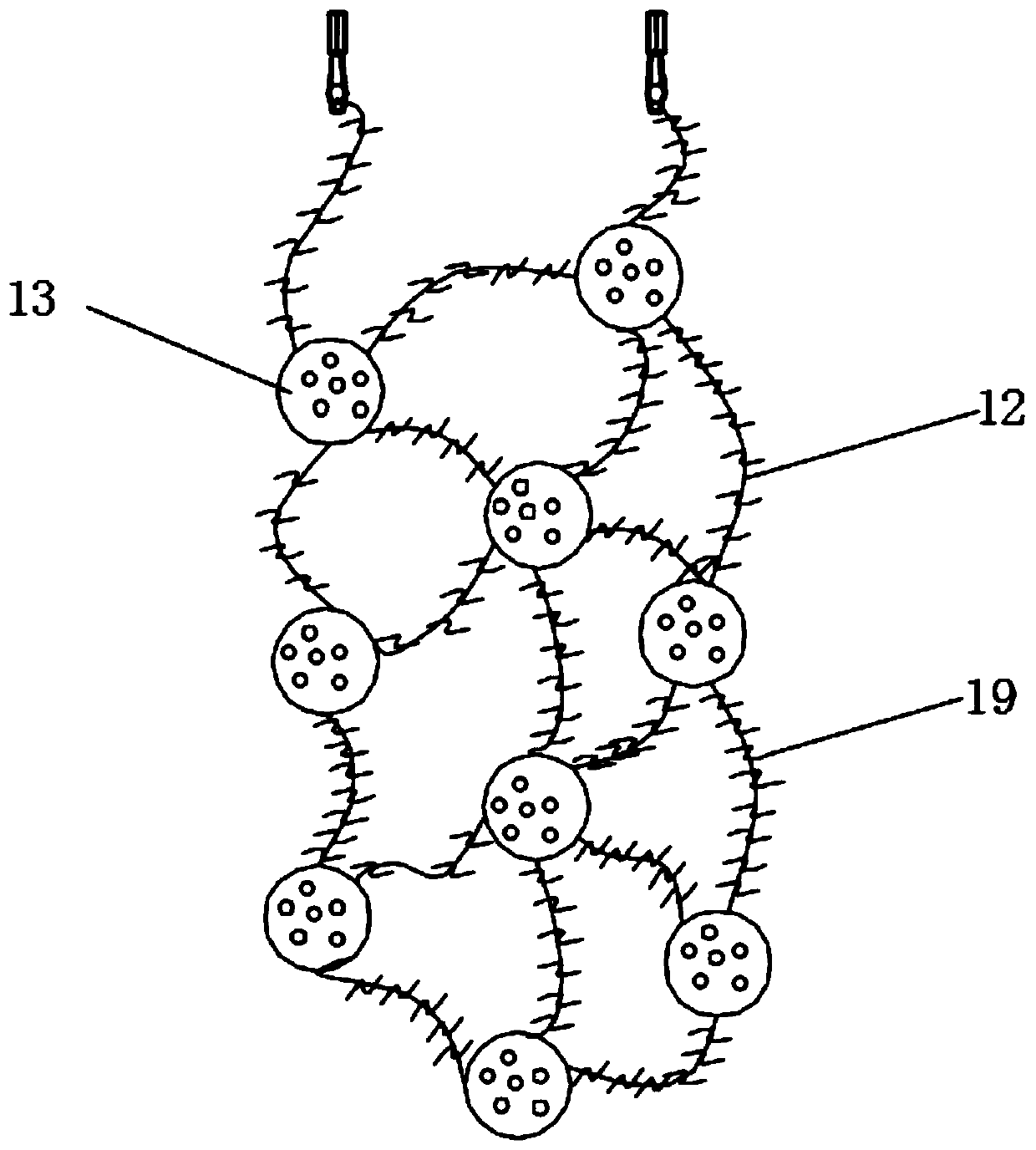

Protecting gloves and weaving method thereof

InactiveCN109736002AGood protection performanceHigh modulusWeft knittingProtective garmentPolyesterYarn

The invention provides a pair of protecting gloves and a weaving method thereof. The weaving method comprises the following step: separately, preparing a first yarn, a second yarn and a third yarn, and weaving the first, second and third yarns to the protecting glove by way of a double-sized weaving method, wherein the first and second yarns are located on one side face of the protecting glove andthe third yarn is located on the other side face of the protecting glove; the first yarn is composed of at least three of polyethylene fibers, glass fibers, stainless steel fibers, spandex yarns andchinlon yarns, the second yarn is composed of aramid fibers, polyester fibers and nylon fibers, and the third yarn is functional fibers and comprises at least one of breathable moisture absorption fibers, antibacterial fibers, far infrared fibers, aromatic fibers or antistatic fibers. The pair of protecting gloves is woven in two sides, so that the yarns in the outer layer have the properties of preventing cutting, wear, puncture and the like, comfort and other auxiliary functions of the gloves are achieved by the yarns in the inner layer, and therefore, an effect of making the best of both worlds is achieved.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

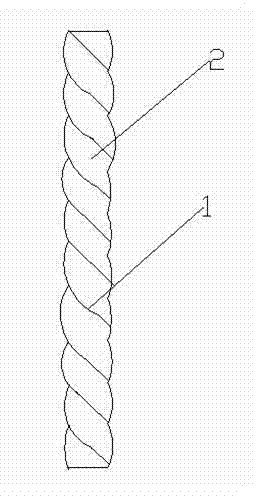

Preparation method of mooring rope for anchoring aircraft carrier

The invention discloses a preparation method of a mooring rope for anchoring an aircraft carrier. Ultra-high molecular weight polyethylene fiber filaments are selected and used, the doubled ultra-high molecular weight polyethylene fiber filaments are twisted and heat-set, and heat-set ultra-high molecular weight polyethylene fiber compound yarns are twisted and formed through a rope twisting machine to obtain the high-performance mooring rope for anchoring the aircraft carrier. The preparation process is simple, safe and reliable, and the prepared mooring rope has abrasion resistance, cutting resistance, puncture resistance, light weight and high strength.

Owner:TAIAN ROPE NET PLASTIC

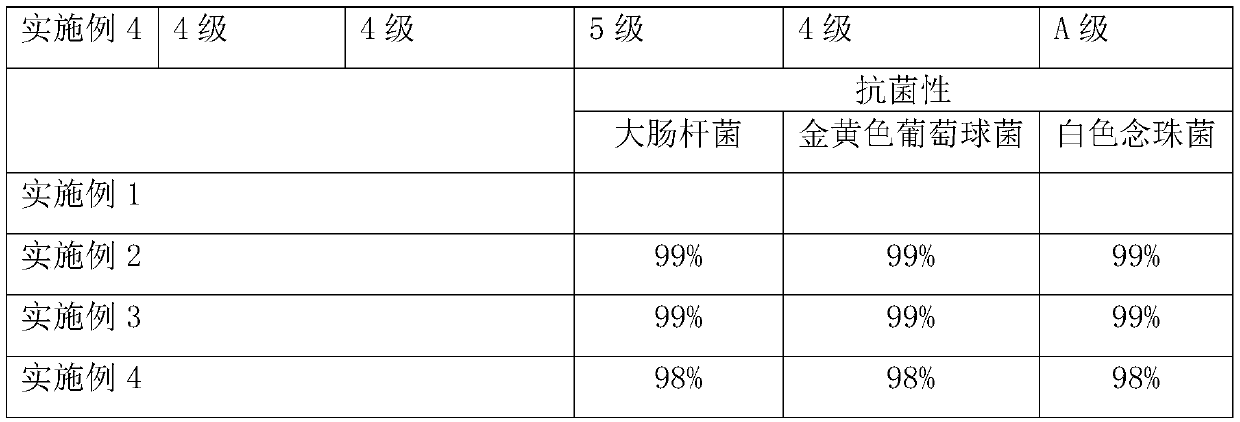

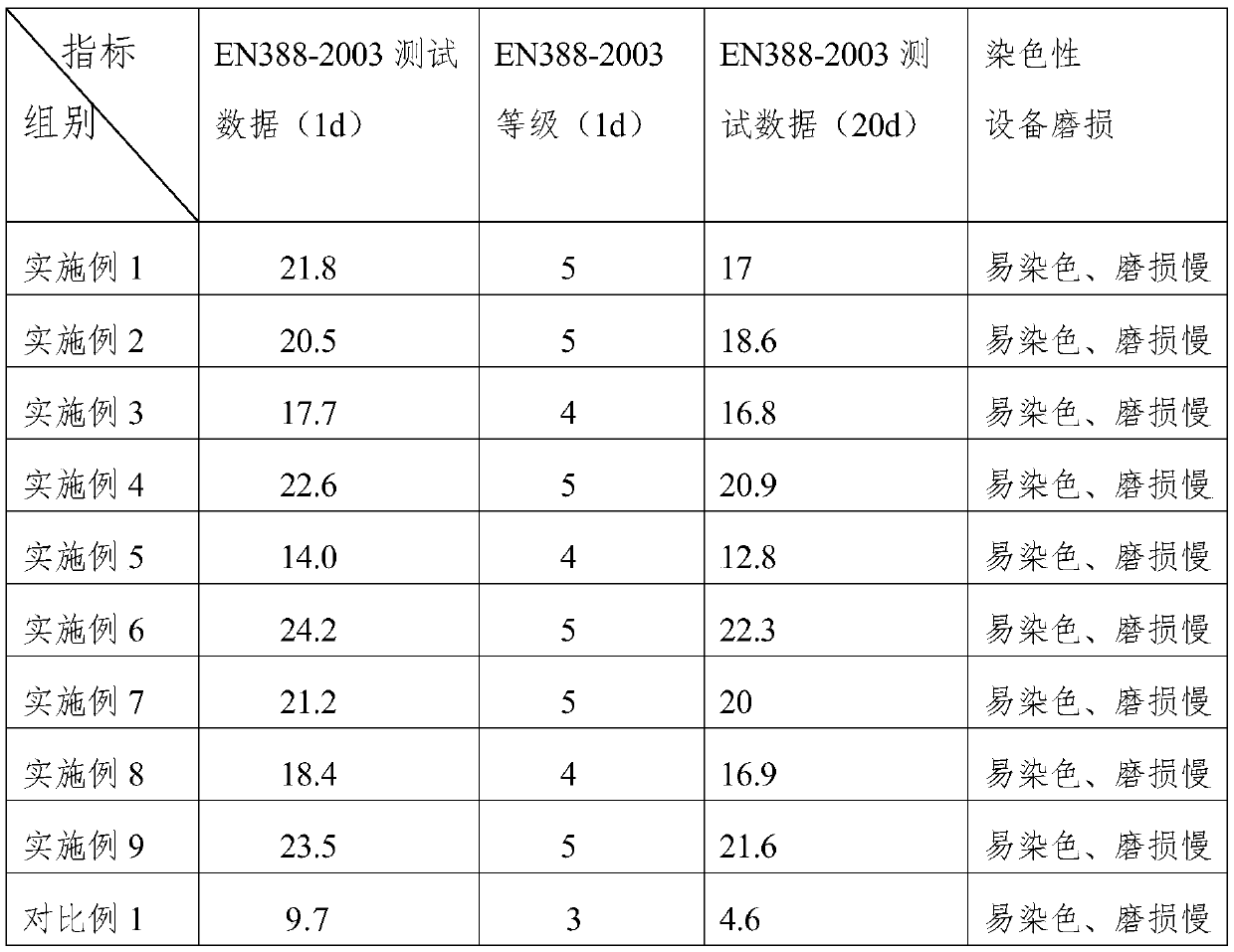

Ultra-high-molecular-weight polyethylene fibers and preparation method thereof

ActiveCN111235665AImprove wearing comfortEasy to wearMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberPolymer science

The present invention relates to ultra-high-molecular-weight polyethylene fibers and a preparation method thereof. The ultra-high-molecular-weight polyethylene fibers contain ultra-high-molecular-weight polyethylene matrixes and boron nitride micron-sized short fibers dispersed in the matrixes, and the content of the boron nitride micron-sized short fibers is 0.25-20wt%. Compared with existing polyethylene fibers filled with other inorganic high hardness reinforcing materials, the ultra-high-molecular-weight polyethylene fibers have the high cutting resistance and easy dyeing property, and because boron nitride has the lubricating property similar to that of graphene, fiber-forming equipment is not damaged. The invention also relates to the preparation method of the ultra-high-molecular-weight polyethylene fibers and anti-cutting gloves or anti-cutting clothing knitted from the ultra-high-molecular-weight polyethylene fibers. It is proved by testing that the gloves knitted from the ultra-high-molecular-weight polyethylene fibers are soft in hand feeling, free of pricking feel and comfortable to wear, and through EN388-2003 testing, the anti-cutting level is 4-5.

Owner:XINGYU SAFETY PROTECTION TECH CO LTD

Knitted glove core, impregnated protective knitted glove comprising same and preparation method and application of impregnated protective knitted glove

The invention provides a knitted glove core, an impregnated protective knitted glove comprising same and a preparation method and application of the impregnated protective knitted glove. The knitted glove core is formed by interweaving first yarn and second yarn, any one or a combination of at least two of nylon, spandex, acrylic fiber or polyester is selected as the first yarn, any one or a combination of at least two of polyimide fiber, polyethylene fiber, aramid fiber, glass fiber, carbon fiber or steel wire is selected as the second yarn, the first yarn is woven on the inner side, and the second yarn is woven on the outer side; and the prepared knitted glove core can selectively have excellent cutting resistance, flame retardance and the like while having good wearing comfort, meanwhile, the overall manufacturing cost can be reduced, and important research significance is achieved.

Owner:WONDERGRIP CHINA CO LTD +1

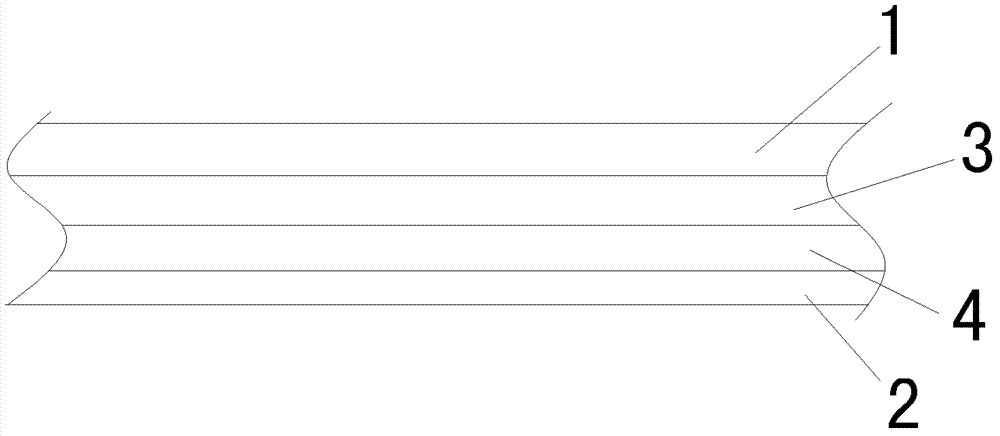

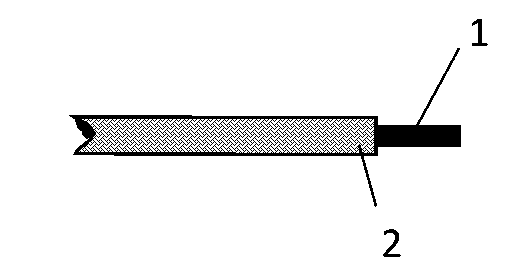

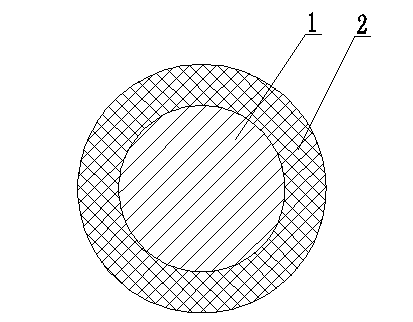

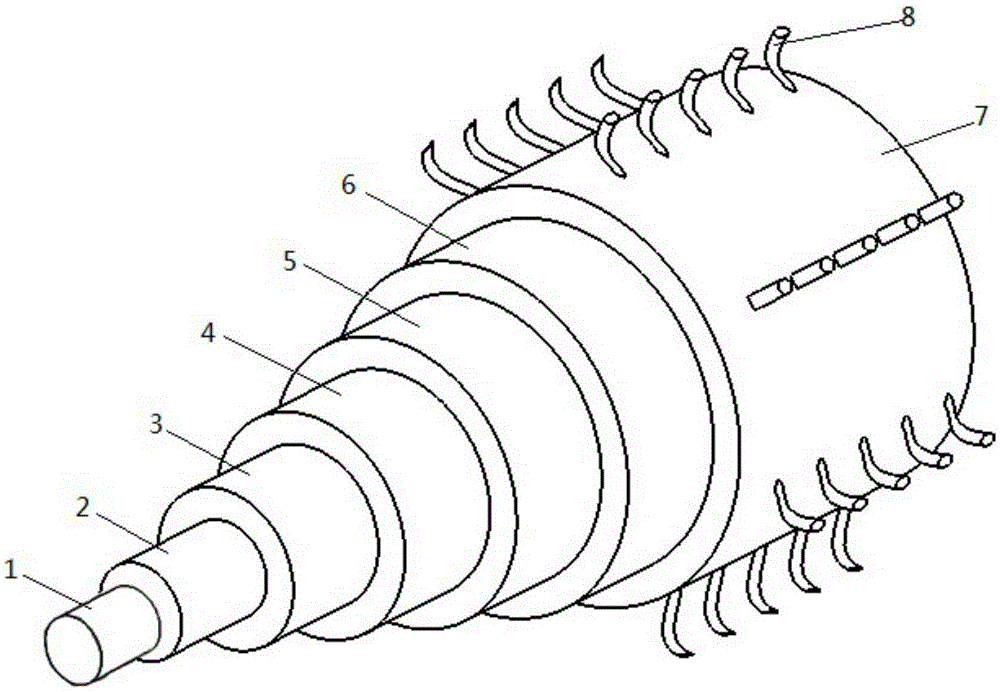

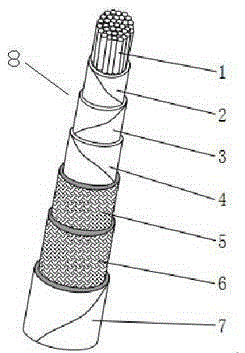

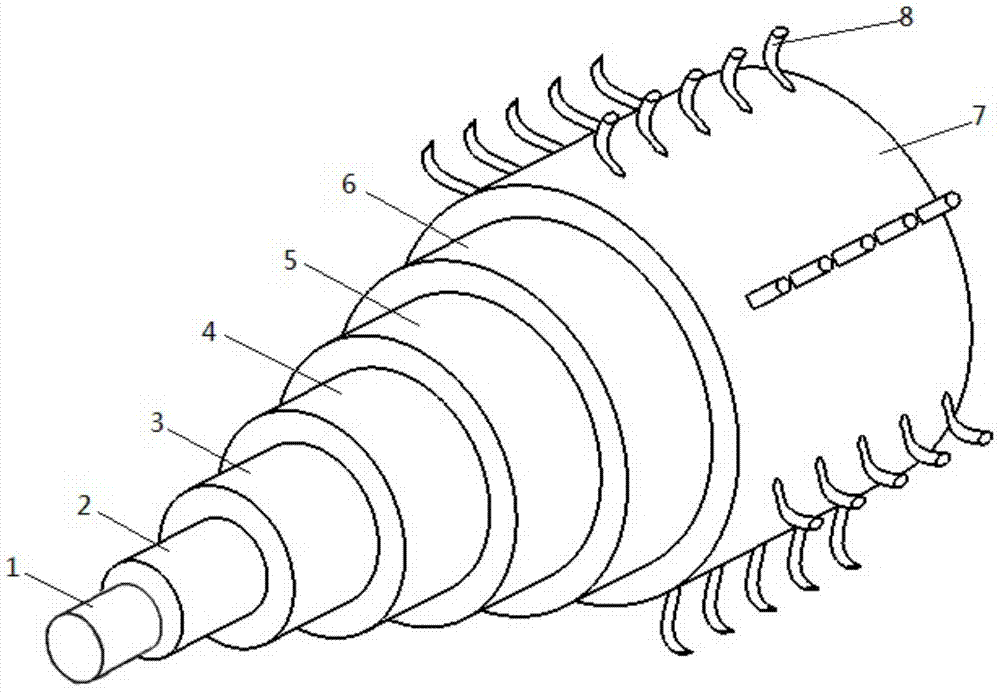

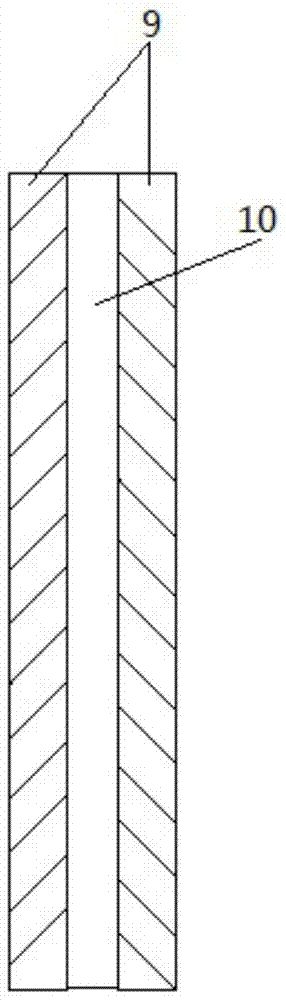

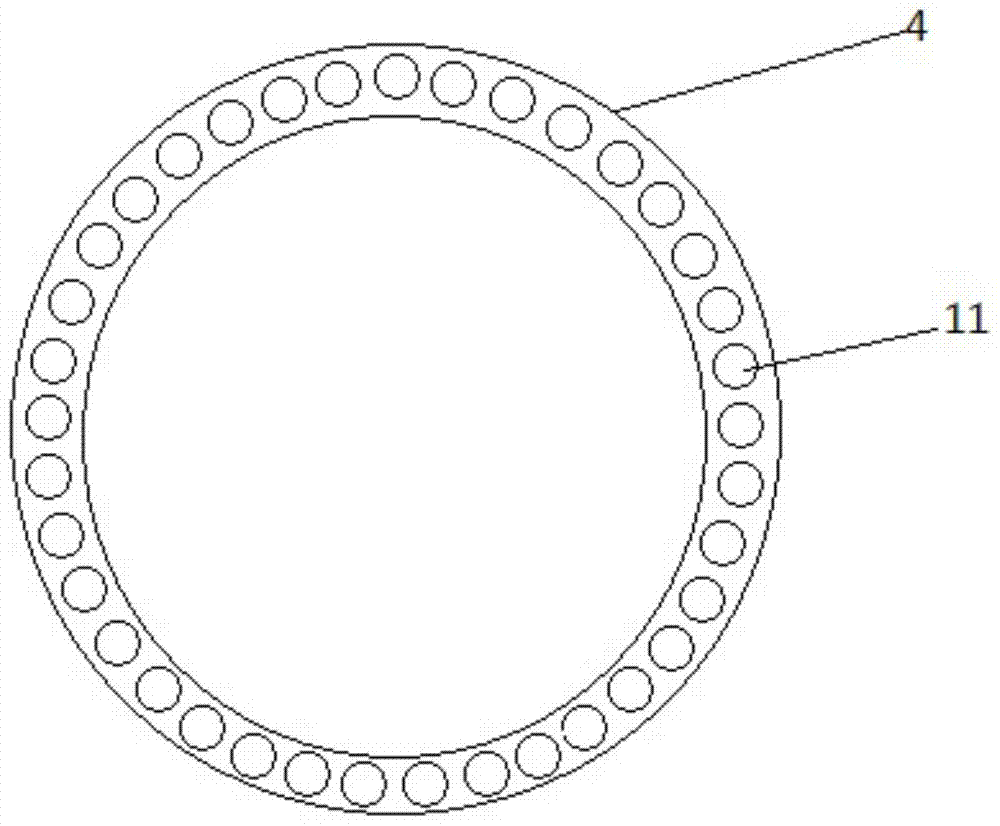

Light precursor cable

ActiveCN105336423AReduce weightHigh tensile strengthInsulated cablesInsulated conductorsShallow seaOptoelectronics

The invention relates to a light precursor cable, comprising a core, a shielding layer, a waterproof layer, a tensile layer, a waterproof wear-resisting layer, a damping layer and a buoyancy layer, wherein the shielding layer coats the core, the waterproof layer coats the shielding layer, the tensile layer coats the waterproof layer, the waterproof wear-resisting layer coats the tensile layer, the damping layer coats the waterproof wear-resisting layer, and the buoyancy layer coats the damping layer. The light precursor cable has the characteristics of light weight, strong tension, wear resistance, small creep deformation, cutting resistance and water repellency; the length of the cable which is sunk into water is reduced under the condition that a float marker is not used, so that power loss of a tractor tug is greatly reduced to significantly reduce the operation difficulty of shallow sea operation.

Owner:曹波

Preparation method of antifouling and antibacterial glove with low surface energy

InactiveCN111363176AWith waterproof functionImprove the protective effectCarbon fibresGlovesAnti bacteriaChemical protection

The invention discloses a preparation method of an antifouling and antibacterial gloves with low surface energy, and belongs to the technical field of high polymer materials. The preparation method issimple, convenient and feasible. Low-surface-energy antifouling latex is adopted as an outer layer and an inner layer of the anti-poison glove, and a phenolic aldehyde-based active carbon fiber composite fabric is used as an adsorption intermediate fiber layer to prepare the antibacterial protective glove with functions of mechanical hazard prevention and high-performance poison prevention. The glove has the advantages of being waterproof, excellent in mechanical protection and chemical protection performance, high in strength, high in rebound resilience, capable of being rapidly processed and produced, wide in application range, environmentally friendly, non-toxic and safe, the inner surface and the outer surface have low surface energy, attachment of microorganism germs and the like canbe effectively prevented, sweat stains can be effectively prevented, and the antifouling and antibacterial capacity is further improved.

Owner:安徽攀望科技有限公司

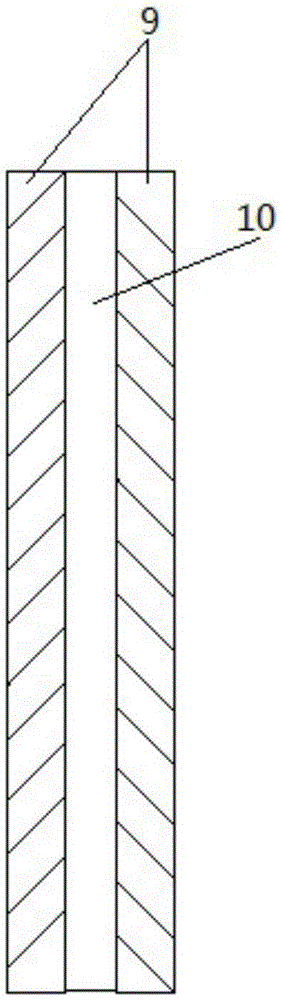

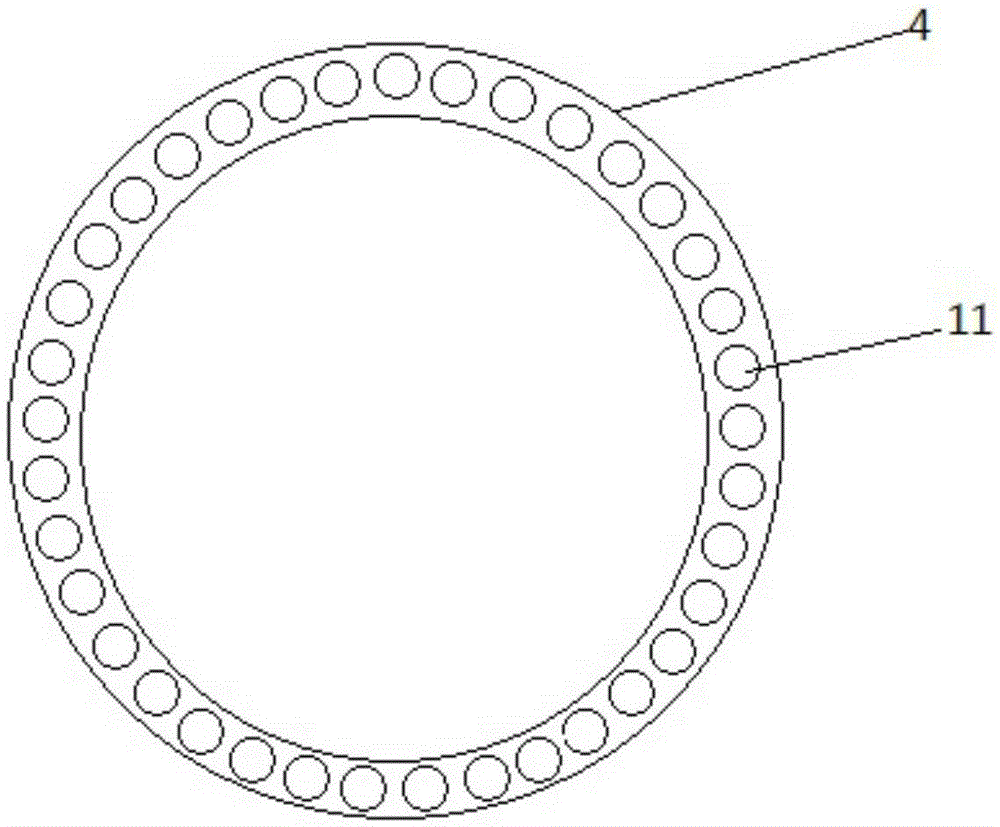

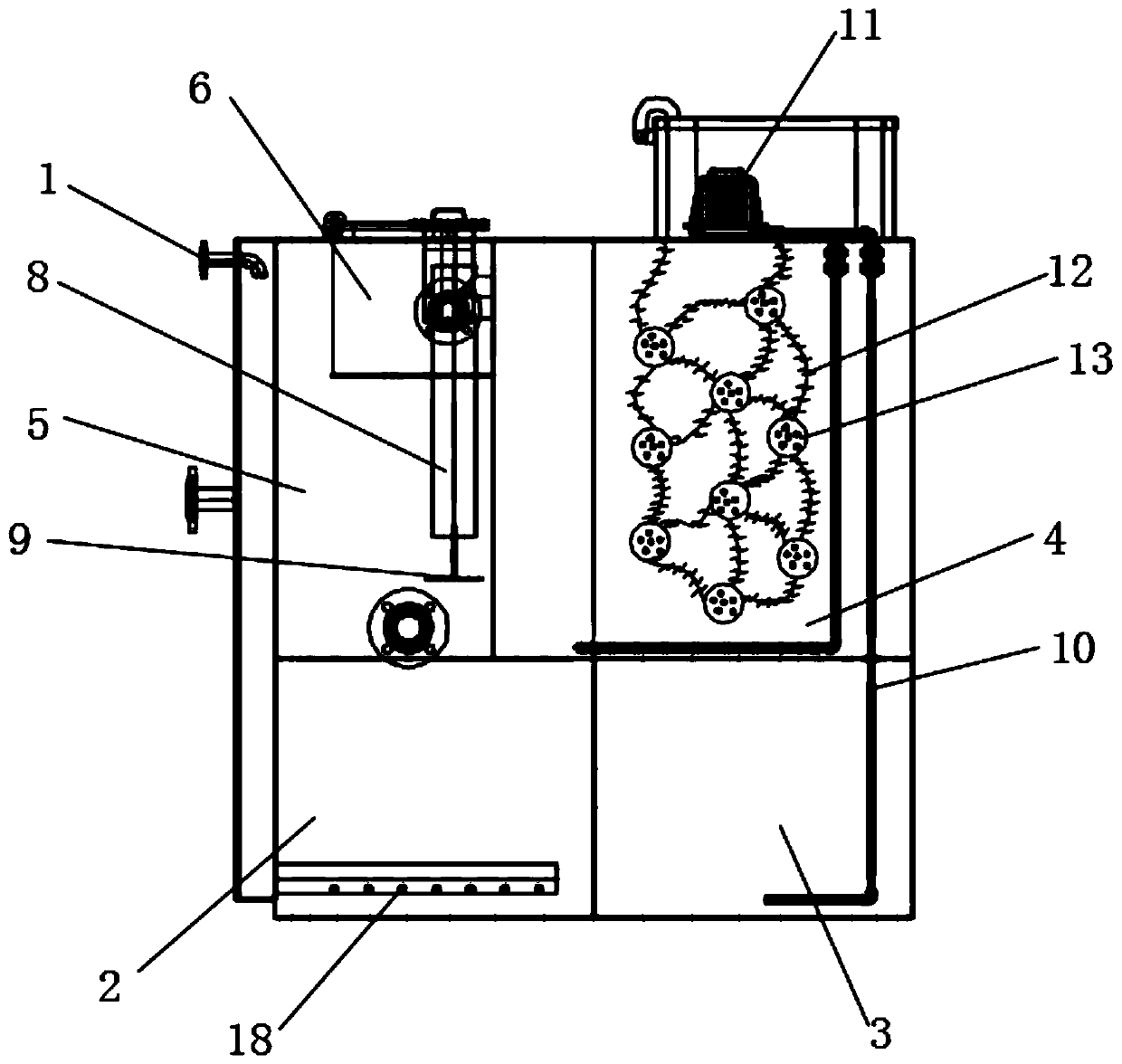

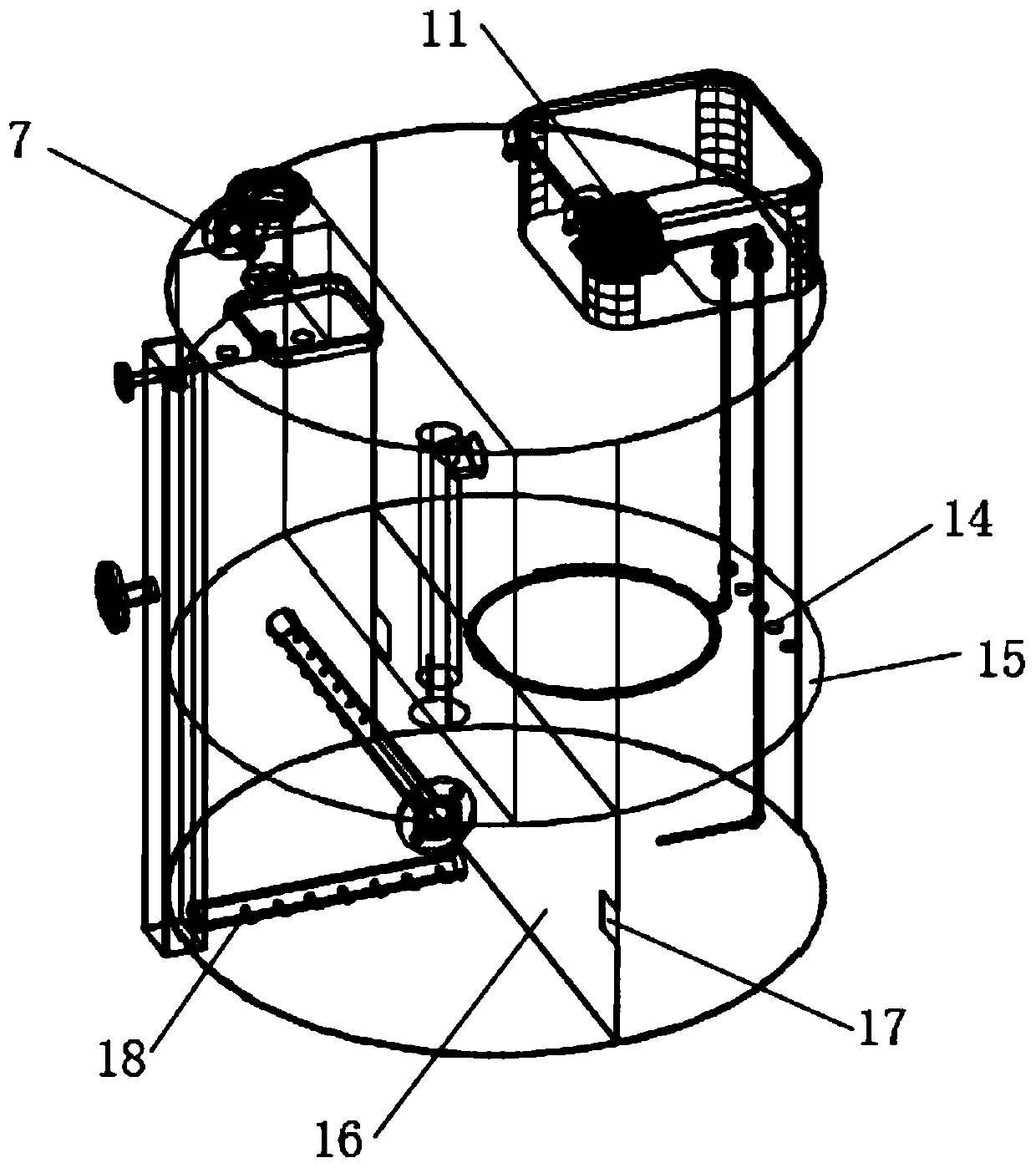

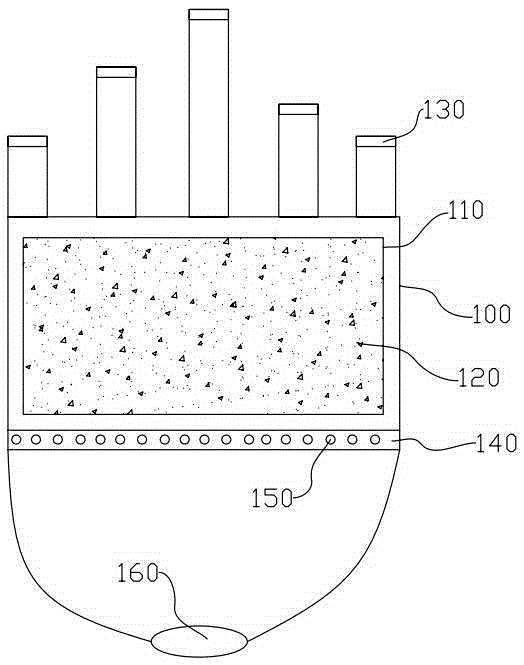

Rural sewage treatment integrated device

PendingCN110127846AEasy to handleImprove processing efficiencyTreatment with aerobic and anaerobic processesSites treatmentRural area

The invention discloses a rural sewage treatment integrated device. The rural sewage treatment integrated device comprises a water inlet pipe, a sewage treatment tank body and an aeration device, wherein the interior of the sewage treatment tank body is divided into an anaerobic zone, an anoxic zone, an aerobic zone and a settling zone which are sequentially communicated. The water inlet pipe is communicated with the anaerobic zone. The anoxic zone and the aerobic zone are aerated through an aeration device. A cobweb type micro-electrolysis treatment system is arranged in the aerobic zone. A clear water area is arranged on the upper side of the settling area, is communicated with the settling area through meshes and is connected with a water outlet pipe. Firstly, the device has the advantages of low investment, low energy consumption, small occupied area, convenience in management and convenience in maintenance; secondly, the device can collect sewage in a small range for on-site treatment, the sewage treatment effect is good, and the treatment efficiency is high. Moreover, the device has outstanding progress in the aspects of denitrification and dephosphorization, and is suitablefor being widely popularized and applied in vast rural areas.

Owner:HUNAN KAITIAN WATER

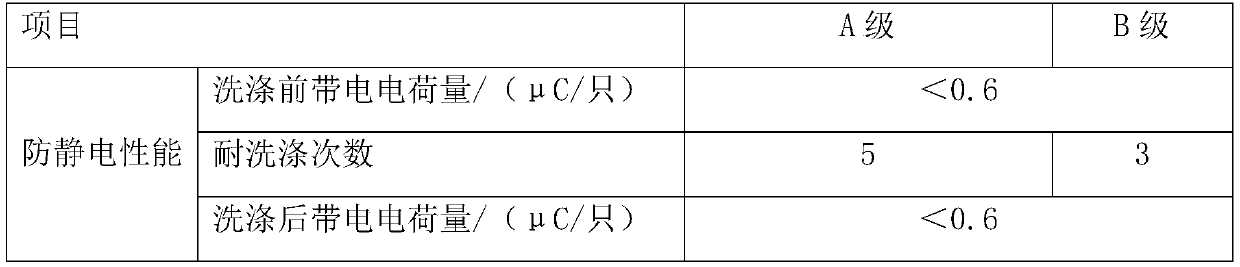

Antistatic cashmere composite fiber containing stainless steel fiber and manufacturing method thereof

The invention discloses antistatic cashmere composite fiber containing stainless steel fiber. The antistatic cashmere composite fiber is prepared by raw materials comprising, by weight, 30-35 parts of berber Fleece, 10-13 parts of rabbit hair, 6-9 parts of soybean protein fiber, 7-10 parts of nanometer bamboo-carbon fiber, 11-14 parts of stainless steel fiber, 5-8 parts of aloe fiber, 4-7 parts of polyethylene glycol distearate, 0.02-0.04 parts of lemon oil, 1.3-2.5 parts of polytetrahydrofuran glycol, 3-5 parts of ethanol amine, 0.6-1.1 parts of nano-TiO2, 2-4 parts of artificial zeolite powder, 1-3 parts of cimicifugae foetidae, 3-4 parts of Mangnolia officinalis, 4-6 parts of pineapple leaves, 110-120 parts of 1-ethyl-3-methylimidazolium acetate, 100-110 parts of 1-allyl-3-methylimidazolium chloride, 20-24 parts of addition agent and appropriate amount of water. The antistatic cashmere composite fiber prepared by the invention has special functions of being anti-static, anti-microbial, mothproof, wear resistant, and anti-radiation and the like.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Sewable tight non-mesh super-strong belt

InactiveCN101275336AWear-resistantCut resistantMonocomponent polyolefin artificial filamentYarnAging resistancePulp and paper industry

The invention discloses a manufacturing method of super strength band with sartorial tight and non mesh, which includes the following steps: a first step, preparing an HSHM-PE fibre, twisting the HSHM-PE fibre through a twisting mill to form an HSHM-PE fibre wire strand; a second step, weaving the HSHM-PE fibre wire strand into a band with tight and non mesh through a weaving band machine. The inventive band body has advantages of high intensity, light weight, good aging resistance index, abrasion-proof, cutting resistant, acid and alkali resistant, greasy dirt resistant, etc.

Owner:袁剑峰

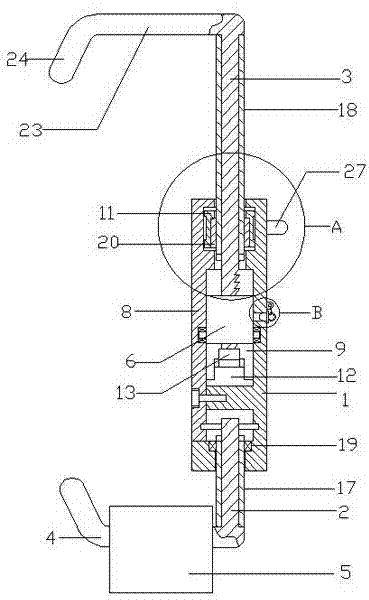

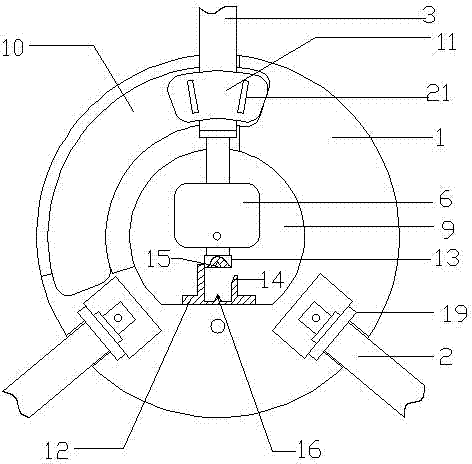

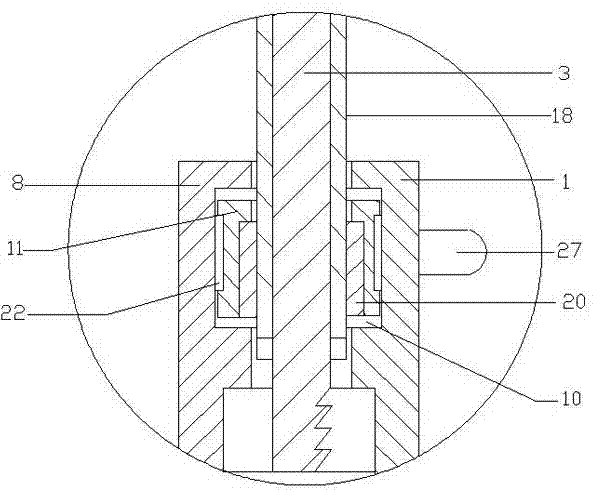

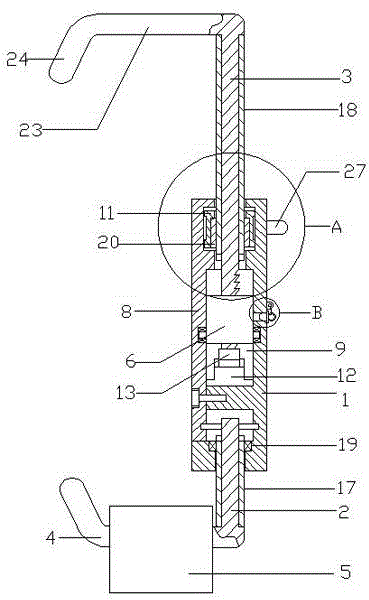

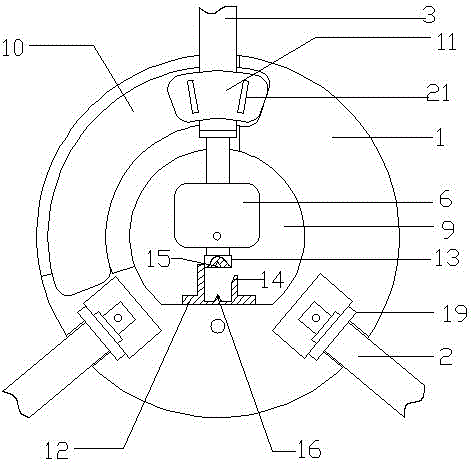

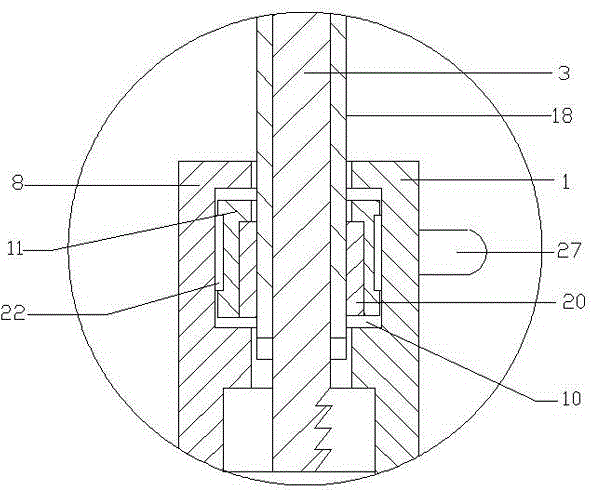

Wheel lock

InactiveCN103317958ASmooth rotationNo interferenceAnti-theft devicesEngineeringMechanical engineering

The invention discloses a wheel lock comprising a lock disc and lock arms, wherein the lower lock arms are positioned on the lower side of the lock disc; the upper arm is positioned on the upper side of the lock disc; jack catches are arranged at the outer ends of the lock arms; stop blocks are arranged on the jack catches of the lower lock arm; a lock body is arranged in the lock disc; a lock hole corresponding to the lock body is formed in the outer side surface of the lock disc; a sealing cover plate is arranged on the inner side surface of the lock disc; a rotating cavity is arranged in the center of the lock disc; the lock body is arranged in the rotating cavity and hinged to the bottom of the rotating cavity, and the hinge point is positioned in the center of the lock disc; an arc-shaped sliding chute is formed in the inner side surface of the lock disc; a sliding block capable of sliding along the arc-shaped sliding chute is arranged in the arc-shaped sliding chute; the excircle arc side of the arc-shaped sliding chute is communicated with the circumference surface of the lock disc; the inner circle arc side of the arc-shaped sliding chute is communicated with the rotating cavity; the lower end of the upper lock arm extends into the lock disc from the circumference surface of the lock disc and penetrates the sliding block to be connected with the lock body. Therefore, the wheel lock has the benefits of being convenient to use, having high universality, being free from influence of the clearance between a wheel arch and a wheel during locking, and being applicable to various types of vehicles.

Owner:ZHEJIANG SCI-TECH UNIV

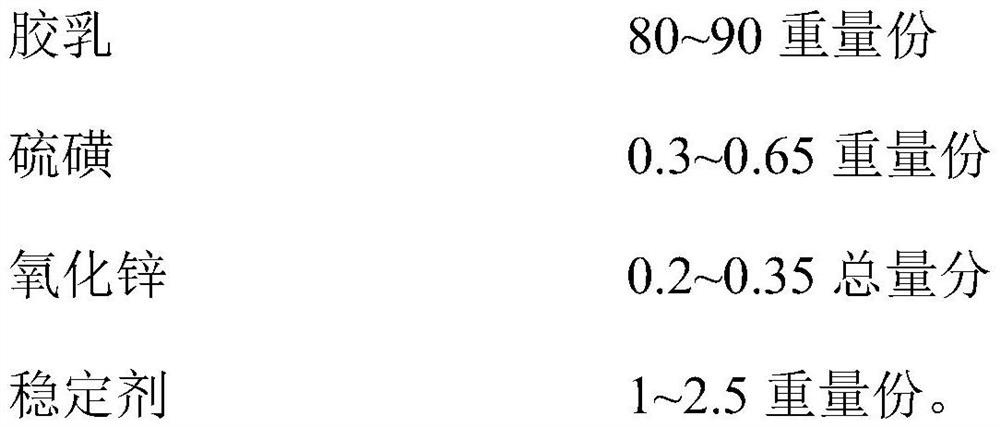

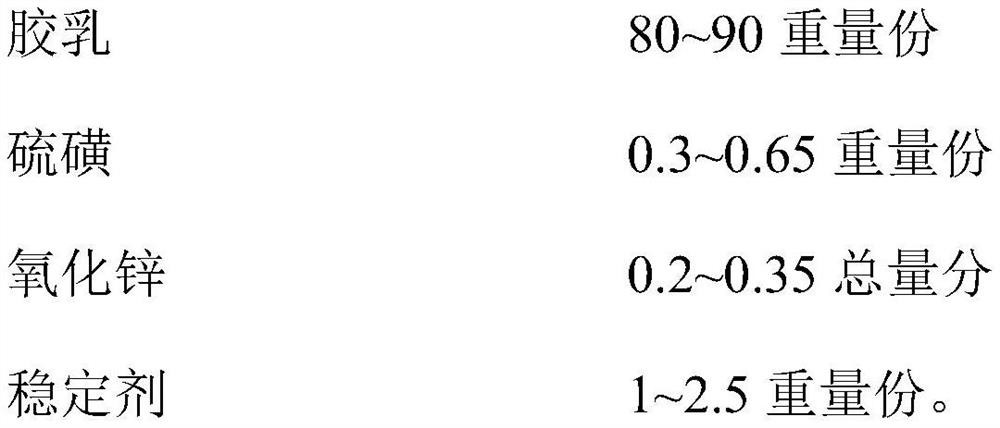

A kind of latex dispensing glove and preparation method thereof

ActiveCN103981723BResistant to chemically aggressive mediaOil resistantSynthetic fibresVegetal fibresPolyesterFiber

The invention relates to a latex dispensing glove and a preparation method thereof, comprising a glove liner and an outer dipping layer, wherein the glove liner is a glove liner seamlessly woven with nylon, polyester, cotton or rayon fibers, and the outer dipping layer is latex outer dipping The outer surface of the latex outer dipping layer is covered with polymer material friction objects; the latex outer dipping layer is composed of the following components: oil-resistant and solvent-resistant rubber or polymer alloy materials or anti-static materials or high-temperature resistant materials, Vulcanizing agents and accelerators. The present invention is covered with polymer material friction materials on the outside of the glove, which isolates the contact between the glove and the object to be held, making the protection of the hand safer and more reliable, and also increases the friction between the glove and the object to be held, making it safe. Easy to apply and can be used for hand protection in a variety of environments.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

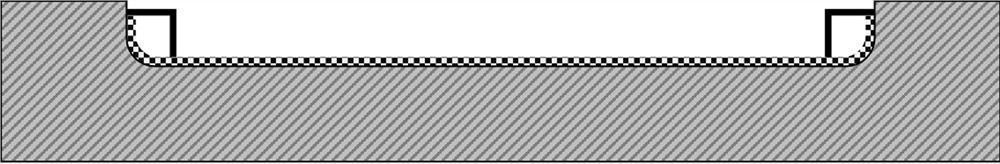

High-pressure wear-resistant portable fire hose

The invention discloses a high-pressure, wear-resistant and portable fire hose, which is braided by warp and latitude threads, and the warp and latitude threads are all high-strength and high-modulus polyethylene fiber materials. The invention has the advantages of light weight, high wear resistance and high pressure resistance, and also has the functions of anti-cutting and anti-chemical.

Owner:JIANGSU NANTONG LONGTAO HOSE GRP CO LTD

High-temperature refractory cable in aero-engine region

InactiveCN105261415AWear-resistantCrack resistantNon-insulated conductorsInsulated cablesElectrical conductorInsulation layer

The invention discloses a high-temperature refractory cable in an aero-engine region. The cable comprises a cable body. The cable body comprises a conductor, an inner insulating layer, an outer insulating layer and an outer sheath layer. The cable body is internally provided with a plurality of conductors. The inner insulating layer is wrapped tightly outside the conductors. The outer insulating layer is extruded outside the inner insulating layer. A heat insulation layer is extruded outside the outer insulating layer. A refractory layer is extruded outside the heat insulation layer. A shielding layer is extruded outside the refractory layer. The outer sheath layer is extruded outside the shielding layer. The cable is reasonable in structural design, convenient to use and resistant to high temperature.

Owner:ANHUI GUANGFU CABLE CO LTD

Method for using graphene-aqueous PU composite slurry to prepare PU gloves

InactiveCN108813763APermanent and strong electrical conductivityImprove wear resistanceGlovesTextiles and paperHeat resistanceSolvent based

The invention discloses a method for using graphene-aqueous PU composite slurry to prepare PU gloves. The method comprises the following steps of S1, weaving of backing materials of the gloves; S2, preparation of a graphene solution, wherein graphene, DMF and an auxiliary are mixed and put for use; S3, preparing of a PU material, wherein solvent-type PU and DMF and the graphene solution in S2 aremixed and put for use; S4, dip-coating, wherein the woven backing materials of the gloves in S1 cover glove molds and are then subjected to dip-coating with the PU material in S3, after dip-coating, aftertreatment is conducted, and then drying and demolding are conducted. The PU gloves are high in conductivity and durability, the wear resistance is greatly improved, and the heat resistance can also be improved; meanwhile, the gloves have low-grade functions of preventing cutting and puncturing.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

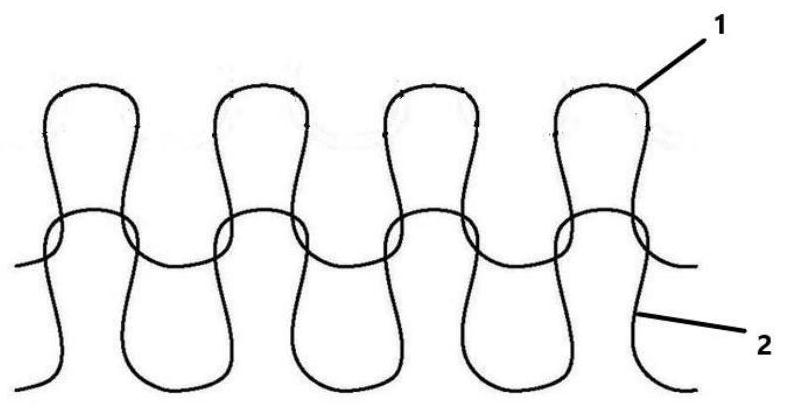

Cutting-preventing gloves used during surgery and preparation method of cutting-preventing gloves

The invention relates to cutting-preventing gloves used during a surgery and a preparation method of the cutting-preventing gloves. Each of the gloves comprises a superfine cutting-preventing fiber knitted inner layer and a gum dipping outer layer, wherein the knitted inner layer is formed through knitting wrap yarn. According to the cutting-preventing gloves disclosed by the invention, the inner lining of the gloves is knitted from the wrap yarn for the first time, then the inner lining is impregnated into rubber, the outer layer is formed, and the double-layer gloves for the surgery are prepared. The gloves are light, thin and soft in hand feeling, have certain cutting preventing capacity, can effectively reduce the risk that a doctor is scratched in the process of the surgery, and can protect hands of the doctor to be safe.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

Method for preparing cutting-resistant mine tire tread rubber

The invention discloses a method for preparing cutting-resistant mine tire tread rubber, and is characterized in that the tread rubber comprises the raw material components by mass: 10-20 parts of natural rubber, 50-60 parts of styrene butadiene rubber, 20-40 parts of oil-extended styrene-butadiene rubber, 1-6 parts of a tearing resistant agent, 5-15 parts of white carbon black, 3-5 parts of a protection system, 5-10 parts of an active agent, 50-65 parts of a reinforcing agent, 5-15 parts of a plasticizer, 1.5-2.5 parts of a vulcanizing agent and 0.5-1.5 parts of a promoter; the raw materialsof the tread rubber are mixed with an internal mixer to prepare the product. The rubber material prepared by the method has the characteristics of resistance to cutting and good containment to a roadsurface, and can avoid the problem that chunking and block falling of rubber after cutting in the use process of a tire.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

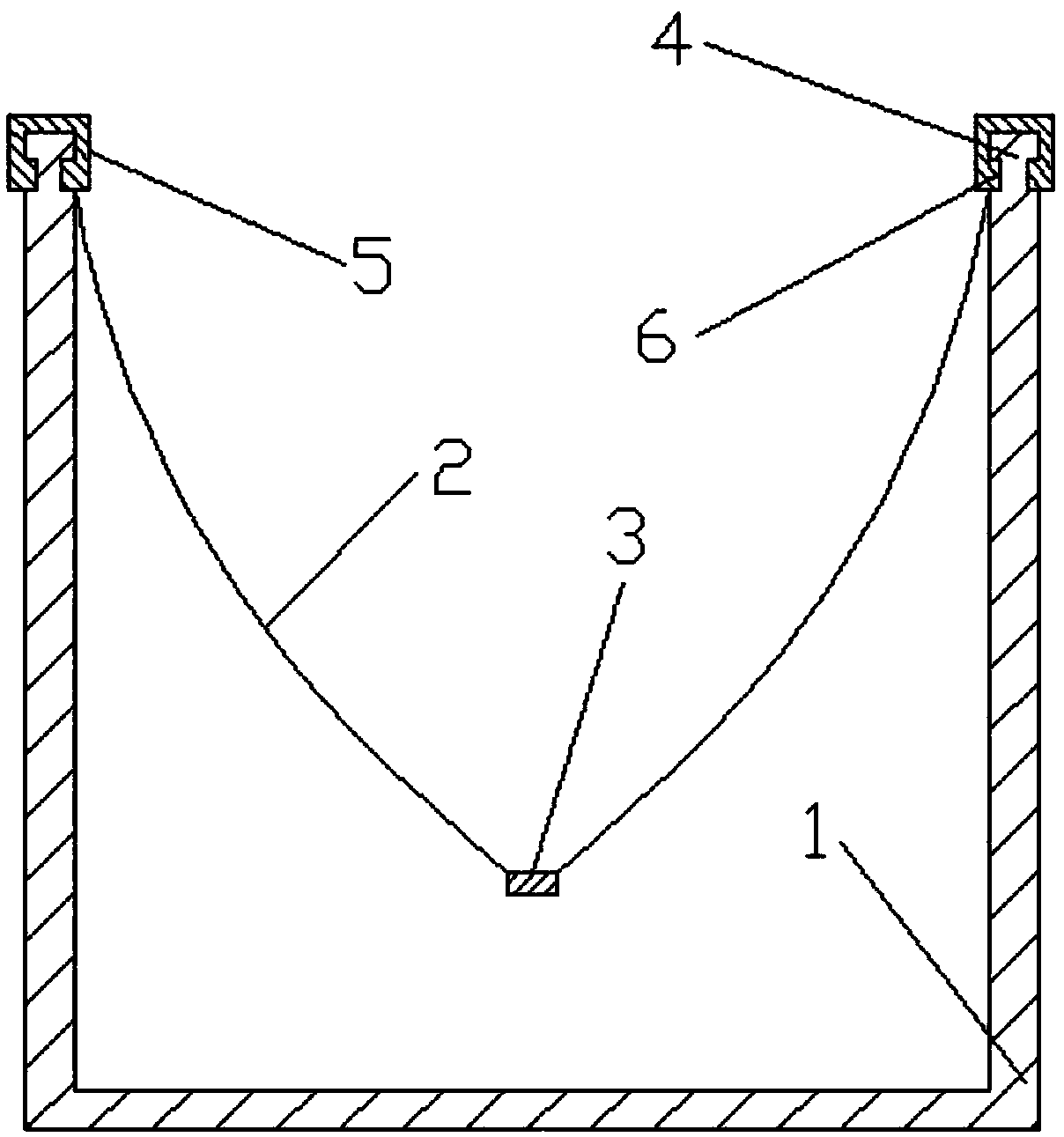

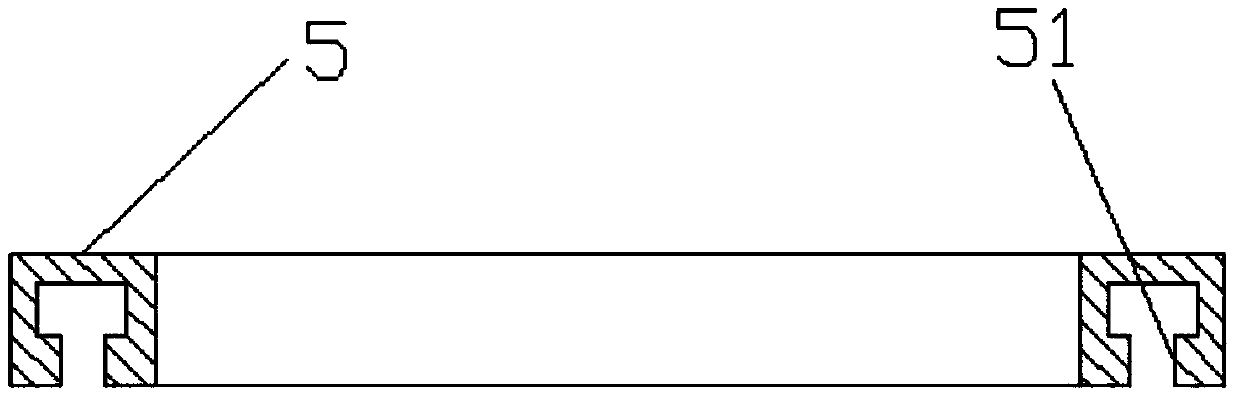

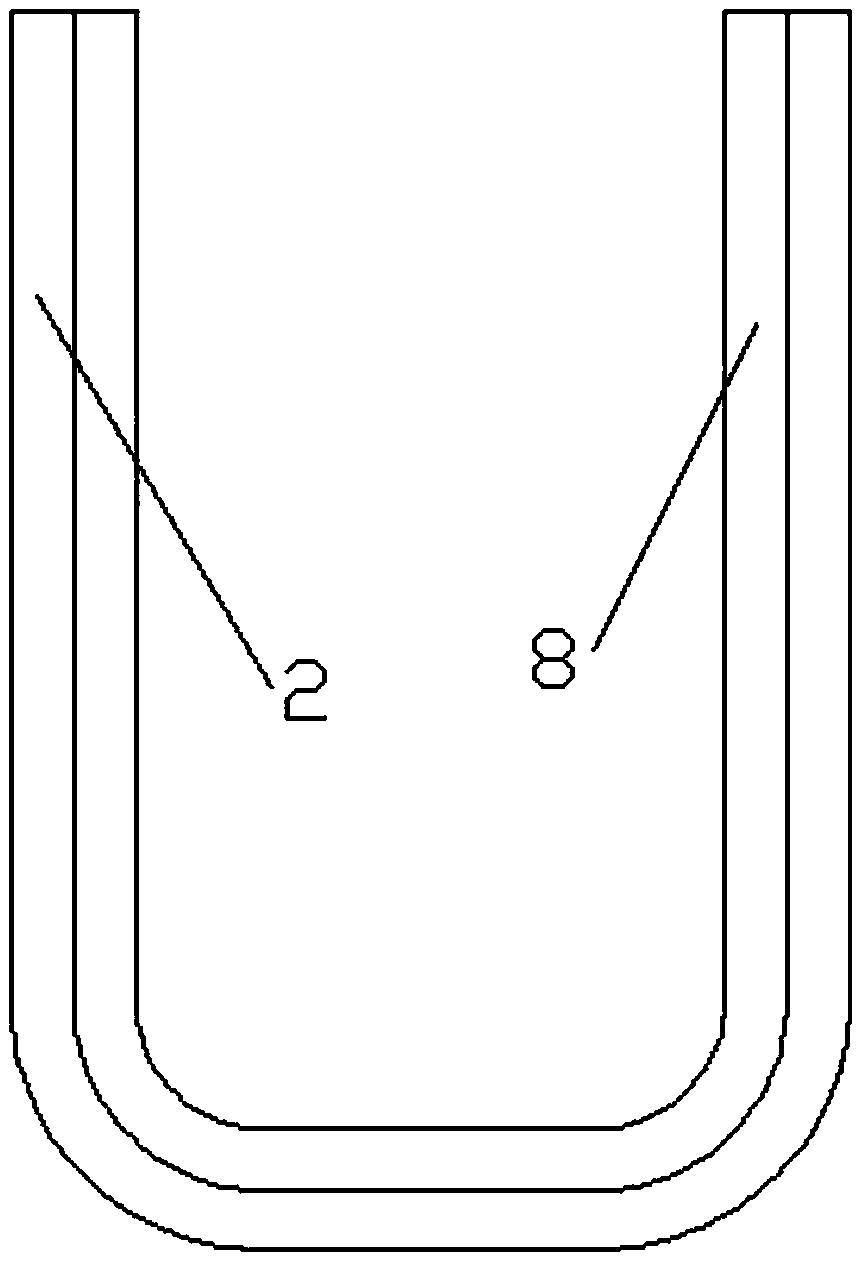

Garbage can with super-hydrophobic garbage bag

PendingCN109533710AHydrophobic hasHydrophobic coating that makes garbage bags cut resistant withRefuse receptaclesEngineeringMechanical engineering

The invention discloses a garbage can with a super-hydrophobic garbage bag. The garbage can comprises a can body; a fastening connection part is arranged on the upper end opening of the can body; thegarbage bag is arranged in the can body; the surface of the garbage bag is coated with a super-hydrophobic layer; a reinforcing edge strip is further arranged on the upper end opening of the garbage bag; the reinforcing edge strip is used for being matched with the fastening connection part; and a saddle weight block is arranged on the bottom of the garbage bag.

Owner:吕一哲

A Lightweight Leading Section Cable

ActiveCN105336423BReduce weightHigh tensile strengthInsulated cablesInsulated conductorsShallow seaEngineering

The invention relates to a light precursor cable, comprising a core, a shielding layer, a waterproof layer, a tensile layer, a waterproof wear-resisting layer, a damping layer and a buoyancy layer, wherein the shielding layer coats the core, the waterproof layer coats the shielding layer, the tensile layer coats the waterproof layer, the waterproof wear-resisting layer coats the tensile layer, the damping layer coats the waterproof wear-resisting layer, and the buoyancy layer coats the damping layer. The light precursor cable has the characteristics of light weight, strong tension, wear resistance, small creep deformation, cutting resistance and water repellency; the length of the cable which is sunk into water is reduced under the condition that a float marker is not used, so that power loss of a tractor tug is greatly reduced to significantly reduce the operation difficulty of shallow sea operation.

Owner:曹波

Protective gloves for factory production

The invention discloses protective gloves for factory production. The protective gloves comprise glove bodies made of cotton threads. Frictional layers are arranged on the outer surfaces of the glove bodies. Buffering cushion layers are arranged on the inner surfaces of the glove bodies. Cut-proof protrusion points made of PU (polyurethane) are evenly distributed on the surfaces of the frictional layers. The interiors of the buffering cushion layers are of hollow structures. Air holes are formed in the surfaces of the buffering cushion layers. The protective gloves have the advantages that the protective gloves can be applied to production lines, have high friction performance and cut-proofing performance and protect hands of workers well; the buffering cushion layers are arranged on inner layers to guarantee sanitation of workers during production; the gloves are low in cost, beneficial to factory production, high in expansibility and safety, novel in design and innovative and have promising market promotion prospect.

Owner:WUXI QISHENG KNITTING GLOVES FACTORY

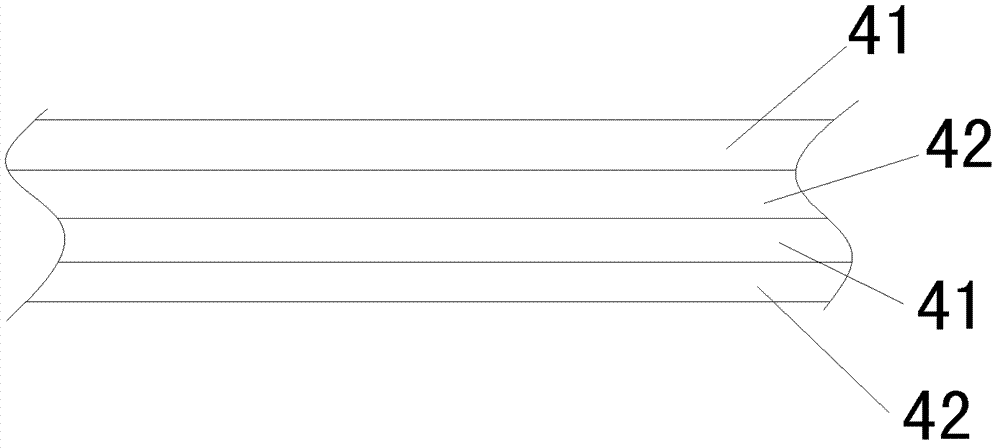

High-cutting-resistance copolymerized spandex wrap yarn and preparation method thereof

The invention belongs to the technical field of wrap yarns and preparation methods thereof, and particularly relates to a high-cutting-resistance copolymerized spandex wrap yarn and a preparation method thereof. The wrap yarn comprises a yarn core, a middle-layer yarn and an outer-layer yarn, wherein the middle-layer yarn is tightly wound on the outer surface of the yarn core according to the dtex: 117.2, and the outer-layer yarn is tightly wound on the outer surface of the middle-layer yarn according to the dtex: 321.7; and the preparation method comprises the steps of weighing by weight, pretreating, copolymerizing the spandex filament wrap yarn and the like. The spandex is set to be a linear polyurethane block copolymer, and aluminum filaments are coated, so that the extensibility of the spandex can be promoted, the fiber fineness of the outer-layer yarn and the middle-layer yarn is further improved, and the tensile strength, the elongation at break and the hardness of the wrap yarn are promoted to be greatly improved; and meanwhile, the preparation method is high in efficiency and low in manufacturing cost, so that the effects of improving the comfort level, being low in manufacturing cost, resisting abrasion, resisting high temperature and being high in cutting resistance are achieved.

Owner:福建南安市汇德纺织科技有限公司

Preparation method of superfine calcium carbonate modified rubber material

The invention discloses a preparation method of a superfine calcium carbonate modified rubber material and belongs to the technical field of preparation of rubber composite materials. The preparation method comprises the steps of carrying out surface modification on super-fine calcium carbonate; plasticating natural rubber NR; burdening ingredients and mixing; preparing a rubber compound film; and carrying out vulcanization treatment on the rubber compound film. By adopting a silane coupling agent to treat superfine calcium carbonate powder and introducing double bond groups onto the surface of the superfine calcium carbonate powder, methyl methacrylate is subjected to free radical polymerization to obtain superfine calcium carbonate / silane coupling agent / methyl methacrylate composite particles in the presence of superfine calcium carbonate / the silane coupling agent. In addition, the rubber is filled with calcium carbonate subjected to grafted modification, so that mechanical properties of the grafted modification system are superior to those of an unmodified filling system; superfine calcium carbonate is dispersed more uniformly in a rubber matrix, and further the compatibility of calcium carbonate and the rubber is improved as well as the use amount of raw rubber is reduced and the cost of products is reduced.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Tread rubber with high-cutting and tearing resistant performance and low-dynamic heat generation

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

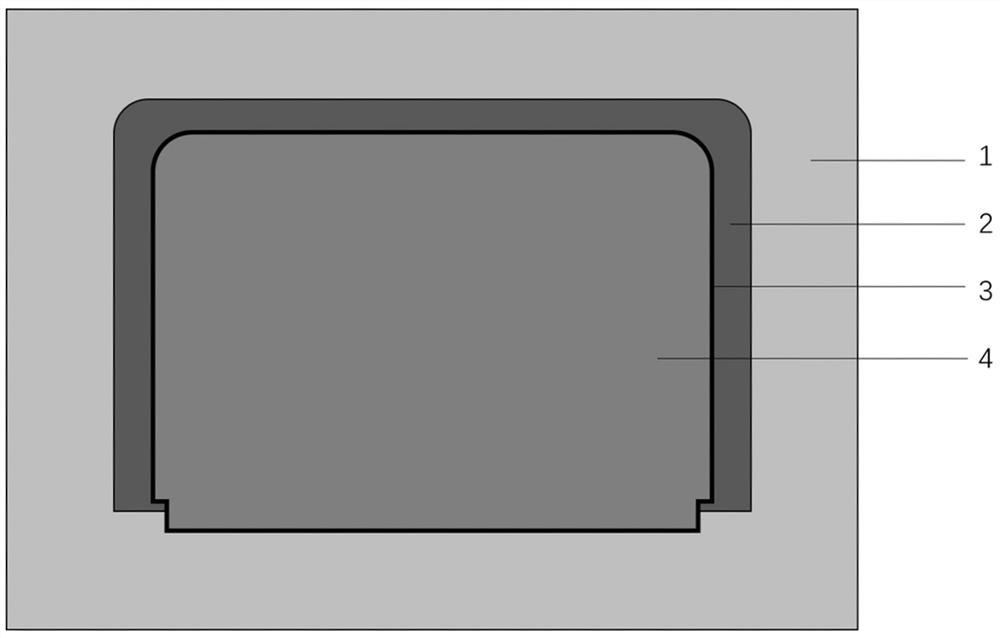

Carbon fiber composite material for reinforcing notebook computer shell and preparation method thereof

The invention provides a carbon fiber composite material for reinforcing a notebook computer shell and a preparation method of the carbon fiber composite material, and belongs to the technical field of composite materials. According to the invention, the bisphenol A type thermosetting epoxy resin is combined with the carbon fiber cloth, so that the carbon fiber cloth has good mechanical propertiesand processing formability, and can play a good role in protecting the whole notebook computer; the polyurethane elastomer has the advantages of being resistant to abrasion, cutting and tearing, highin bearing capacity, transparent or semitransparent, resistant to ozone, pourable, pourable and wide in hardness range, the polyurethane elastomer is combined with the carbon fiber cloth to serve asa buffer area of the shell, a large amount of impact energy can be absorbed, and a good buffer effect on mechanical impact is achieved. According to the preparation method, a partition ternary integrated polymerization method is adopted, bisphenol A thermosetting epoxy resin and a polyurethane elastomer are crosslinked and combined into a whole in the heat treatment process through a silane coupling agent, and it is guaranteed that different components can exert the maximum effect in corresponding protection areas.

Owner:北京中超伟业信息安全技术股份有限公司

a wheel lock

InactiveCN103317958BSmooth rotationNo interferenceAnti-theft devicesMechanical engineeringHinge point

The invention discloses a wheel lock comprising a lock disc and lock arms, wherein the lower lock arms are positioned on the lower side of the lock disc; the upper arm is positioned on the upper side of the lock disc; jack catches are arranged at the outer ends of the lock arms; stop blocks are arranged on the jack catches of the lower lock arm; a lock body is arranged in the lock disc; a lock hole corresponding to the lock body is formed in the outer side surface of the lock disc; a sealing cover plate is arranged on the inner side surface of the lock disc; a rotating cavity is arranged in the center of the lock disc; the lock body is arranged in the rotating cavity and hinged to the bottom of the rotating cavity, and the hinge point is positioned in the center of the lock disc; an arc-shaped sliding chute is formed in the inner side surface of the lock disc; a sliding block capable of sliding along the arc-shaped sliding chute is arranged in the arc-shaped sliding chute; the excircle arc side of the arc-shaped sliding chute is communicated with the circumference surface of the lock disc; the inner circle arc side of the arc-shaped sliding chute is communicated with the rotating cavity; the lower end of the upper lock arm extends into the lock disc from the circumference surface of the lock disc and penetrates the sliding block to be connected with the lock body. Therefore, the wheel lock has the benefits of being convenient to use, having high universality, being free from influence of the clearance between a wheel arch and a wheel during locking, and being applicable to various types of vehicles.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com