Composite fiber and articles made therefrom

A technology for yarns, blends, and applications in the field of cut-resistant composite yarn structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

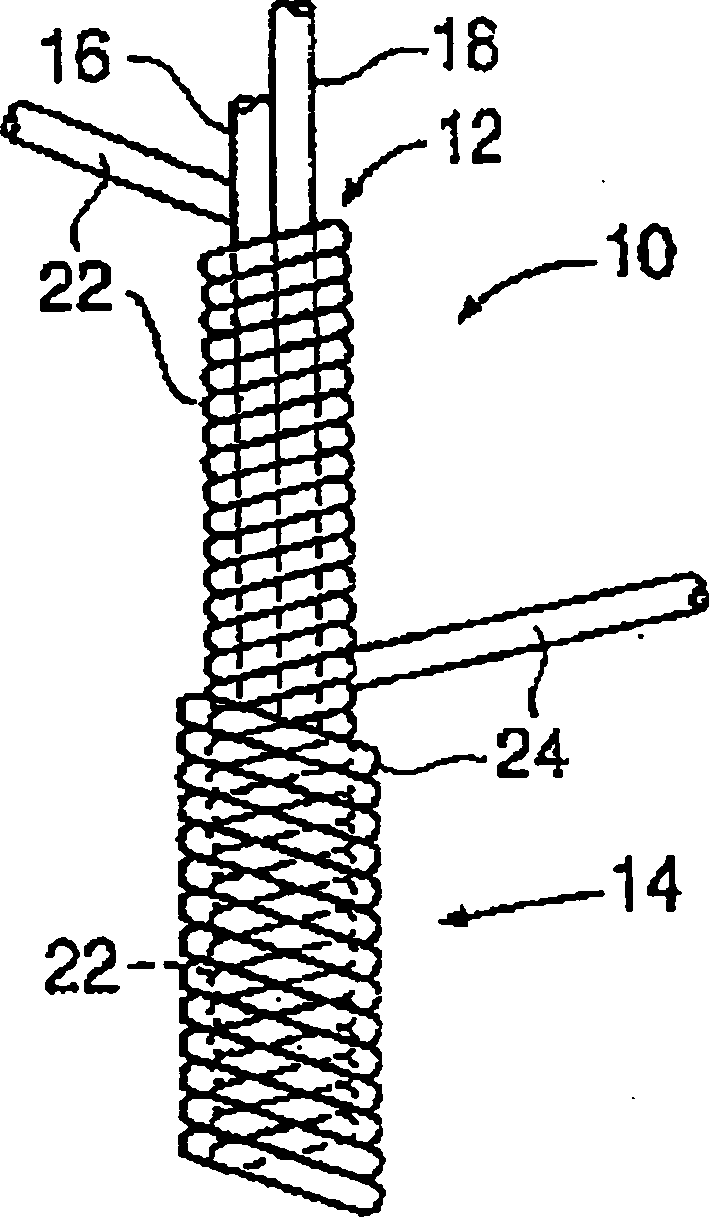

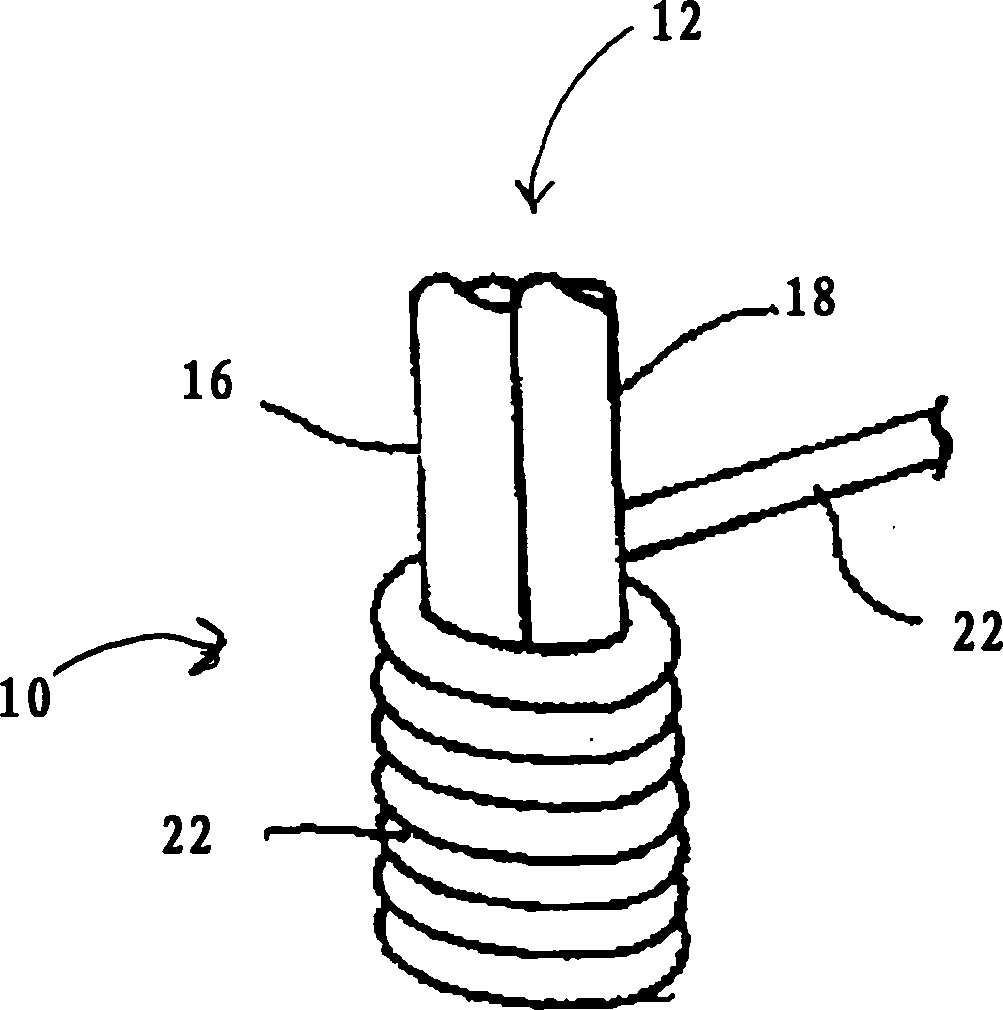

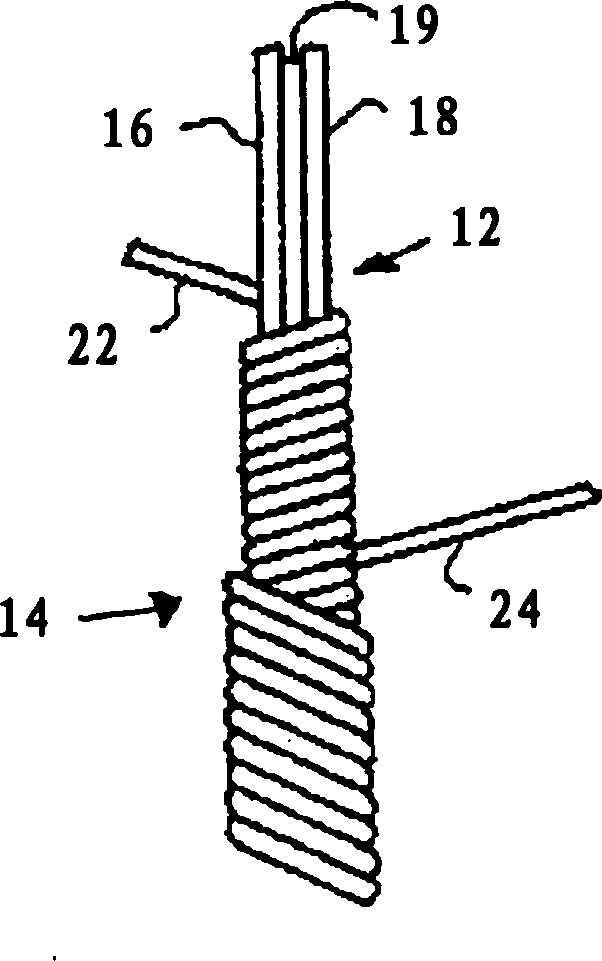

[0037] By way of non-limiting example, yarn constructions showing various embodiments of the invention are shown in Table 2 below as Examples 1-5. Examples 6-9 are included as control experiments and will be described hereinafter. "-X" in the nomenclature refers to the number of strands used for the particular composite yarn composition. In each case, the first and second wrapping layers wrap in opposite first and second directions (in the case of a third wrapping layer, it wraps in the same direction as the first layer and in the same direction as the second layer wrap in the opposite direction).

[0038] the core

example

No

Glass

Wire diameter

(inch)

first cladding layer

Second cladding layer

third cladding layer

Composite yarn denier

1

G-450 2X0.0016

parallel

150 denier

9.4tpi

150 denier

8.2tpi

623

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com