Exhaust gas dedusting, denitration and desulfuration method for thermal power plant

A technology for thermal power plants and flue gas, which is applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of reduced thermal efficiency of boilers, increased primary air and flue gas, and poor heat transfer effects, and can achieve the purpose of catalyst use. The effect of less amount, high denitration efficiency and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the method of the present invention will be described below in conjunction with the accompanying drawings.

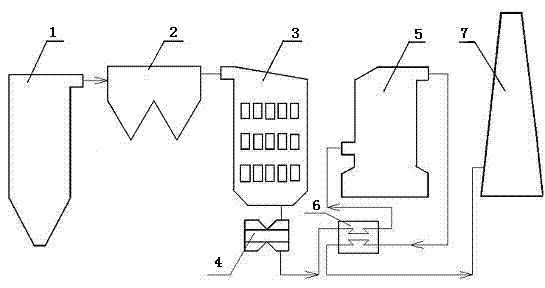

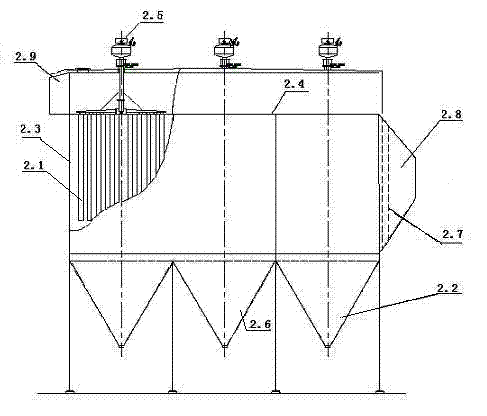

[0014] Such as figure 1 , the high-temperature flue gas (temperature is 380°C~400°C) discharged from the boiler 1 of the thermal power plant is filtered and dusted by the bag filter 2 and then enters the SCR reactor 3 for catalytic reaction, so that the NO in the flue gas X reduced to N 2 Then the high-temperature flue gas enters the air preheater 4 to exchange heat with the air, and the temperature of the flue gas at the outlet of the air preheater 3 reaches 150-160°C, and then passes through the heat exchanger 6 to exchange heat with the low-temperature flue gas after desulfurization, and the flue gas The gas temperature drops to 90-100°C, enters the desulfurization tower 5, and sprays the rising flue gas in the tower with limestone slurry to absorb the SO 2 , the generated gypsum slurry settles to the bottom of the tower, after desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com