Hybrid fabric by employing ultrahigh molecular weight polyethylene fiber and aramid fiber

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of mixed fabrics, can solve the problems of poor interfacial compatibility and creep resistance, uneven glue content, and easy generation of pores in the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

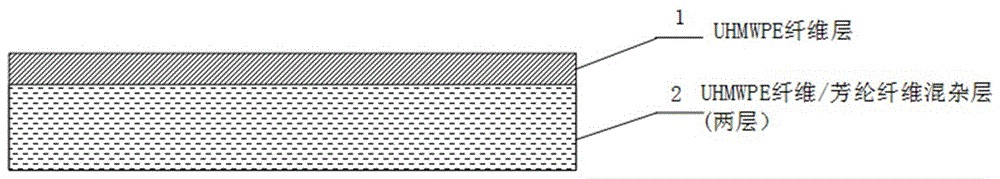

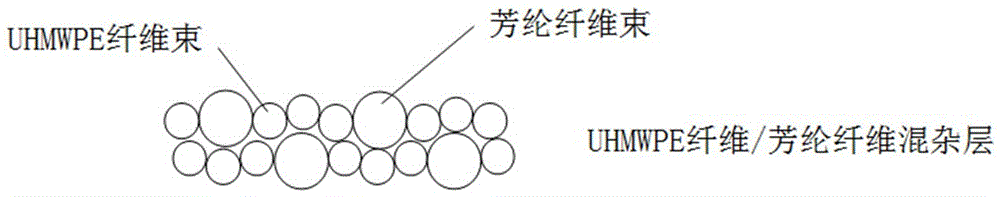

[0026] Example 1: UHMWPE fiber and aramid fiber of the present invention, the volume ratio of UHMWPE fiber and aramid fiber is 3:1, and the thickness is 0.16mm.

[0027] UHMWPE fiber layer, the amount of fiber bundles is 200g / m 2 , thickness 0.04mm.

[0028] The UHMWPE fibers used were surface treated with an oxidation solution of 3 parts of potassium dichromate, 6 parts of deionized water, and 90 parts of concentrated sulfuric acid before weaving.

[0029] The surface of UHMWPE fiber was modified with 1wt% silane coupling agent KH560.

[0030] The fiber bundles of the fiber layer composed of the UHMWPE fiber and the aramid fiber are arranged in parallel and juxtaposed in one direction. In order to avoid air holes that may occur when there are too many layers caused by the different diameters of the two fibers, a layer of UHMWPE fiber layers is laid on one side of every two layers of mixed braided layers, and finally the edge is seamed.

[0031] When the fiber content of th...

Embodiment 2

[0033] Example 2: UHMWPE fiber and aramid fiber of the present invention, the volume ratio of UHMWPE fiber and aramid fiber is 2:1, and the thickness is 0.16mm;

[0034] UHMWPE fiber layer, the amount of fiber bundles is 200g / m 2 , thickness 0.04mm.

[0035] The UHMWPE fibers used were surface treated with an oxidation solution of 7 parts of potassium dichromate, 10 parts of deionized water, and 110 parts of concentrated sulfuric acid before weaving.

[0036] The surface of UHMWPE fibers was modified with 2wt% silane coupling agent KH560.

[0037] The fiber bundles of the fiber layer composed of the UHMWPE fiber and the aramid fiber are arranged in parallel and juxtaposed in one direction. In order to avoid air holes that may occur when there are too many layers caused by the different diameters of the two fibers, a layer of UHMWPE fiber layers is laid on one side of every two layers of mixed braided layers, and finally the edge is seamed.

[0038] When the fiber content of...

Embodiment 3

[0040] Example 3: UHMWPE fiber and aramid fiber of the present invention, the volume ratio of UHMWPE fiber and aramid fiber is 1:1, and the thickness is 0.16mm;

[0041] UHMWPE fiber layer, the amount of fiber bundles is 200g / m 2 , thickness 0.04mm.

[0042] The UHMWPE fibers used were surface treated with an oxidation solution of 5 parts of potassium dichromate, 8 parts of deionized water, and 100 parts of concentrated sulfuric acid before weaving.

[0043] The surface of UHMWPE fiber was modified with 3wt% silane coupling agent KH560.

[0044] The fiber bundles of the fiber layer composed of the UHMWPE fiber and the aramid fiber are arranged in parallel and juxtaposed in one direction. In order to avoid air holes that may occur when there are too many layers caused by the different diameters of the two fibers, a layer of UHMWPE fiber layers is laid on one side of every two layers of mixed braided layers, and finally the edge is seamed.

[0045] When the fiber content of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com