Ultra-high-molecular-weight polyethylene fibers and preparation method thereof

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the field of man-made fibers, and can solve problems such as reduced efficiency, high hardness of inorganic high-hardness materials, and equipment wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

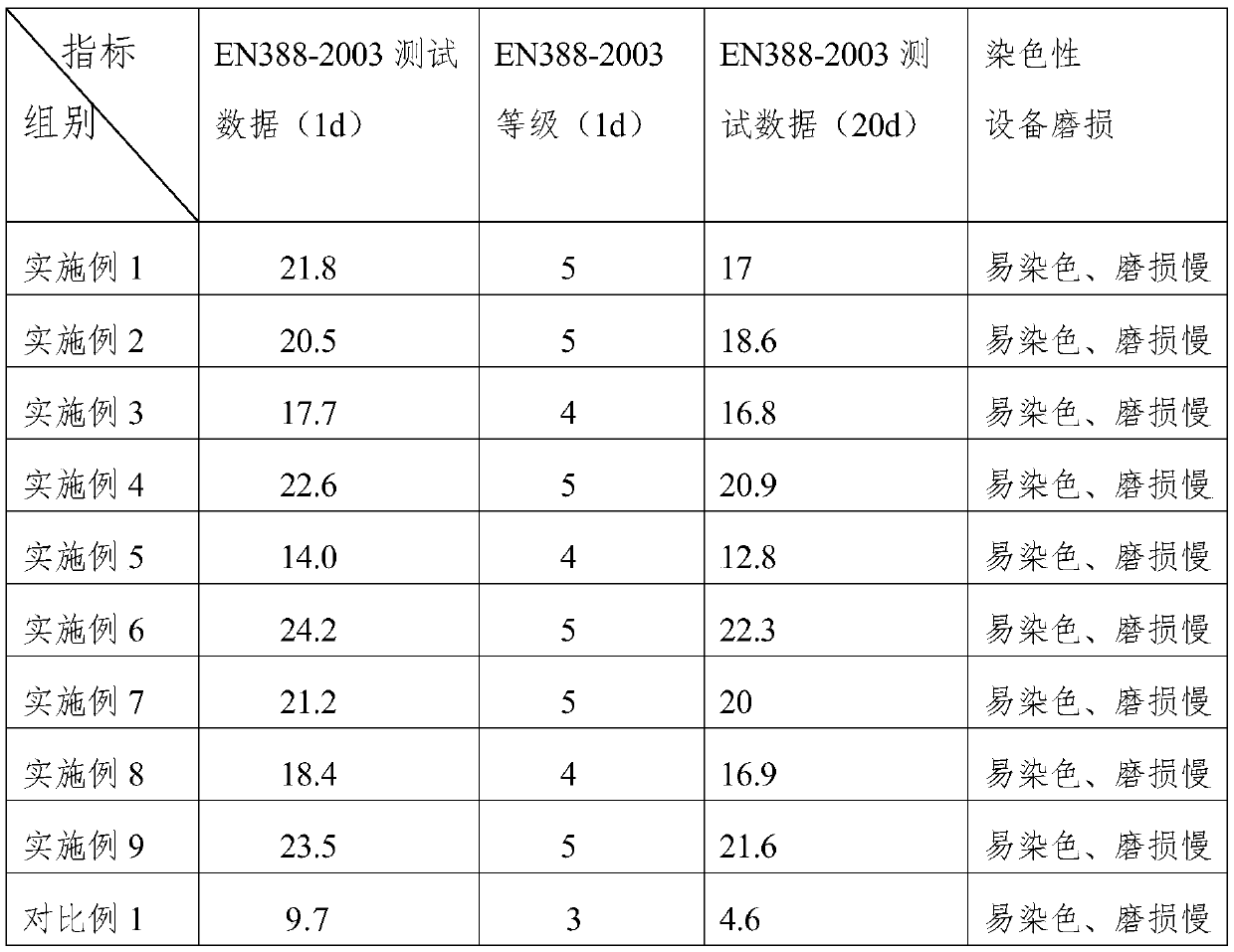

Examples

Embodiment 1

[0059] The present embodiment provides a kind of preparation method of ultra-high molecular weight polyethylene fiber, and it comprises the steps:

[0060](1) Get the 1200g boron nitride micron short fiber that length is 10-20um, be dispersed in 5Kg white oil, add surfactant linear alkylbenzene sulfonate sodium (LAS) 300g, high-speed stirring is evenly emulsified, obtains emulsified material.

[0061] (2) Put the above-mentioned emulsified material and 15kg of ultra-high molecular weight polyethylene powder with a molecular weight of 2 million and an average particle size of 100um into 95Kg white oil, stir and mix at high speed for 0.5h, heat to 70°C for 2h, stir and mix 0.5h, repeat until completely swelled to obtain a mixture.

[0062] (3) blending and extruding the mixture through a twin-screw extruder, cooling and molding in a coagulation bath to obtain a primary fiber, and the resulting primary fiber is extracted, dried, and multi-stage hot drawn to make a white super H...

Embodiment 2

[0065] The present embodiment provides a kind of preparation method of ultra-high molecular weight polyethylene fiber, and it comprises the steps:

[0066] (1) getting length is 20-40um 1200g surface has some microporous boron nitride micron short fibers, dispersed in 5Kg white oil, add surfactant linear alkylbenzene sulfonate sodium (LAS) 300g, Stir at high speed to emulsify evenly to obtain emulsified material.

[0067] (2) Put the above-mentioned emulsified material and 15kg of ultra-high molecular weight polyethylene powder with a molecular weight of 2 million and an average particle size of 100um into 95Kg white oil, stir and mix at high speed for 0.5h, heat to 70°C for 2h, stir and mix 0.5h, repeat until completely swelled to obtain a mixture.

[0068] (3) blending and extruding the mixture through a twin-screw extruder, cooling and molding in a coagulation bath to obtain a primary fiber, and the resulting primary fiber is extracted, dried, and multi-stage hot drawn to ...

Embodiment 3

[0071] The present embodiment provides a kind of preparation method of ultra-high molecular weight polyethylene fiber, and it comprises the steps:

[0072] (1) Take 1000g of boron nitride micron-sized short fibers with a length of 20-30um, dissolve them in 1L of 5mol / L sodium hydroxide solution, stir at 120°C for 12h, and rinse with deionized water for 3 times after suction filtration , and dried at 60°C to obtain surface hydroxylated boron nitride micron short fibers.

[0073] (2) Make acetone and dilute hydrochloric acid with a pH of 3 into a solution at a volume ratio of 9:1, add 50 g of coupling agent KH570, hydrolyze at 60°C for 1 hour, and then use the surface hydroxylated product obtained in the above (1) Boron nitride micron-sized short fibers are added to the solution, mixed with the hydrolyzed coupling agent, stirred at 50°C for 3 hours, filtered with suction, rinsed with deionized water for 3 times, and dried to obtain nitrogen modified by the surface coupling agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com