Garbage can with super-hydrophobic garbage bag

A garbage bag and super-hydrophobic technology, applied in the field of environmental hygiene products, can solve the problems of easy contamination with dirt and viruses, soil air pollution, etc., and achieve the effects of simple structure, easy dumping, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

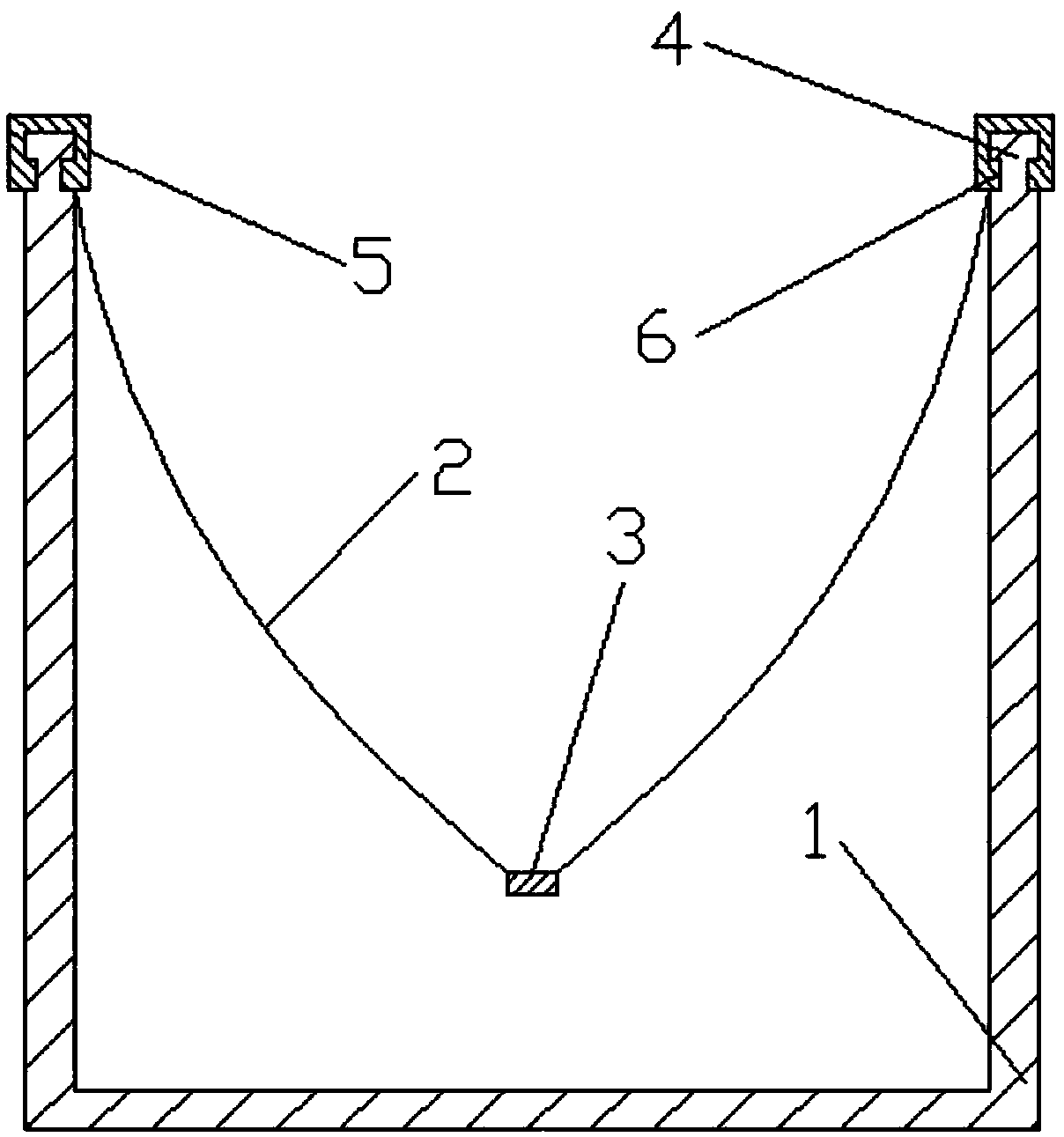

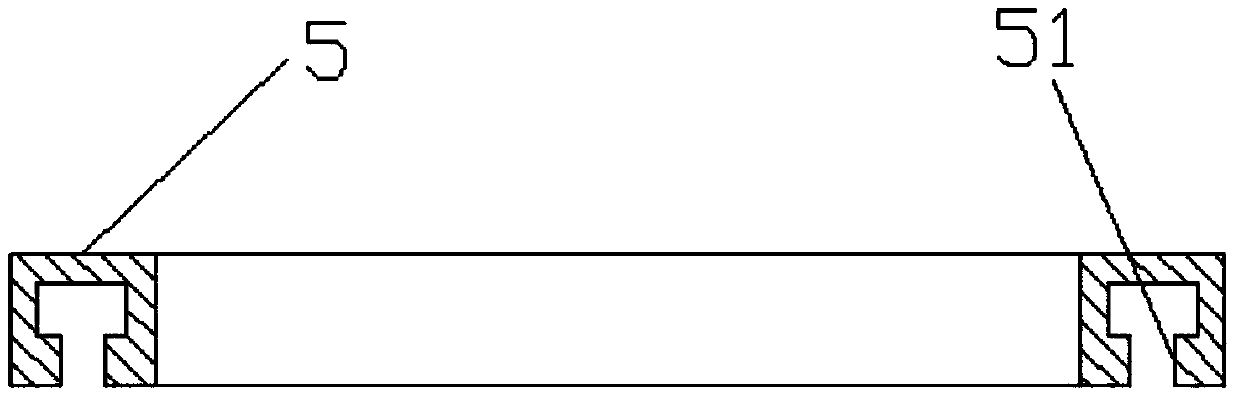

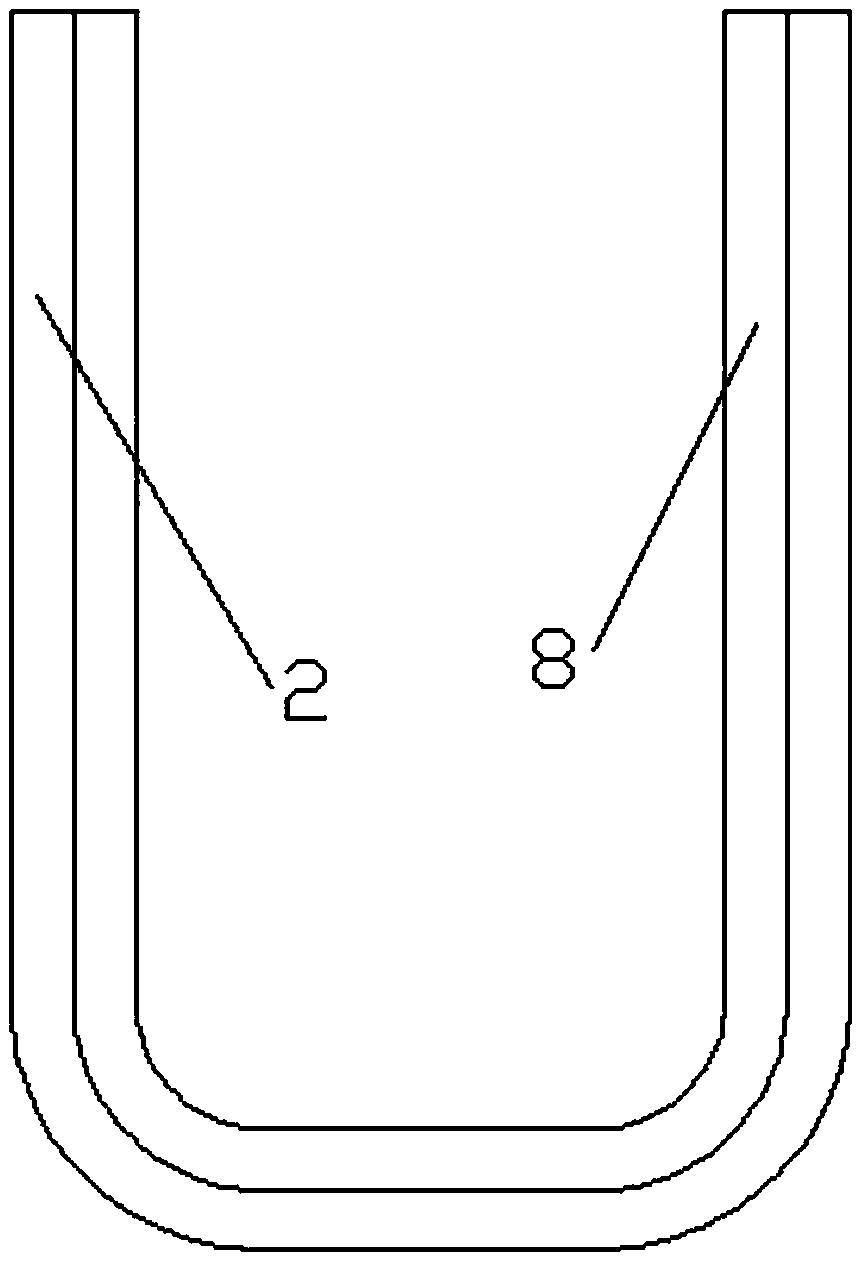

[0023] Such as Figure 1 to Figure 3 As shown, a trash can with a superhydrophobic garbage bag includes a barrel body 1, the upper port of the barrel body 1 is provided with a fastening connection part 4; the barrel body 1 is provided with a garbage bag 2, and the garbage bag 2 can be made of Kelaf cloth, the purpose is to achieve the purpose of anti-cutting, anti-puncture and anti-damage of the garbage bag 2, the present invention is coated with a super-hydrophobic coating 8 on the surface of the garbage bag 2, and the super-hydrophobic Material coating 8 can be wherein a kind of of polytetrafluoroethylene, polycarbonate or polyamide material; The upper port of described garbage bag 2 is also provided with reinforcement sideband 5; The fastening connection part 4 fits; the bottom of the garbage bag 2 is provided with a weight block 3 .

[0024] The present invention adopts different connection structures for fixing the barrel body and the garbage bag respectively, to replace...

Embodiment 2

[0028] Such as Figure 5 and Figure 6 As shown, another way of fixing the barrel body and the garbage bag of the present invention: the fastening connection part 4 is composed of a socket connection structure, bolt holes are arranged at equal intervals around the upper port of the barrel body 1, and the The bolt hole is fixed with the reinforcement sideband 5 with the fixing hole that the port on the garbage bag is provided with by the bolt 7 . After pressing the garbage bag with the reinforced sideband, punch a hole on the reinforced sideband. The hole should penetrate the garbage bag and into the upper end of the garbage bin. The garbage bags are combined to achieve the purpose of fixing the garbage bags.

Embodiment 3

[0030] The third way of fixing the barrel body and the garbage bag of the present invention is: the fastening connection part 4 is formed by a buckle-type connection structure, and the upper port of the barrel body 1 is provided with an eversion-type flanging, and the eversion-type After the flanging is overlapped with the upper port of the garbage bag 2, it is fixed by the buckle opening of the reinforced side belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com