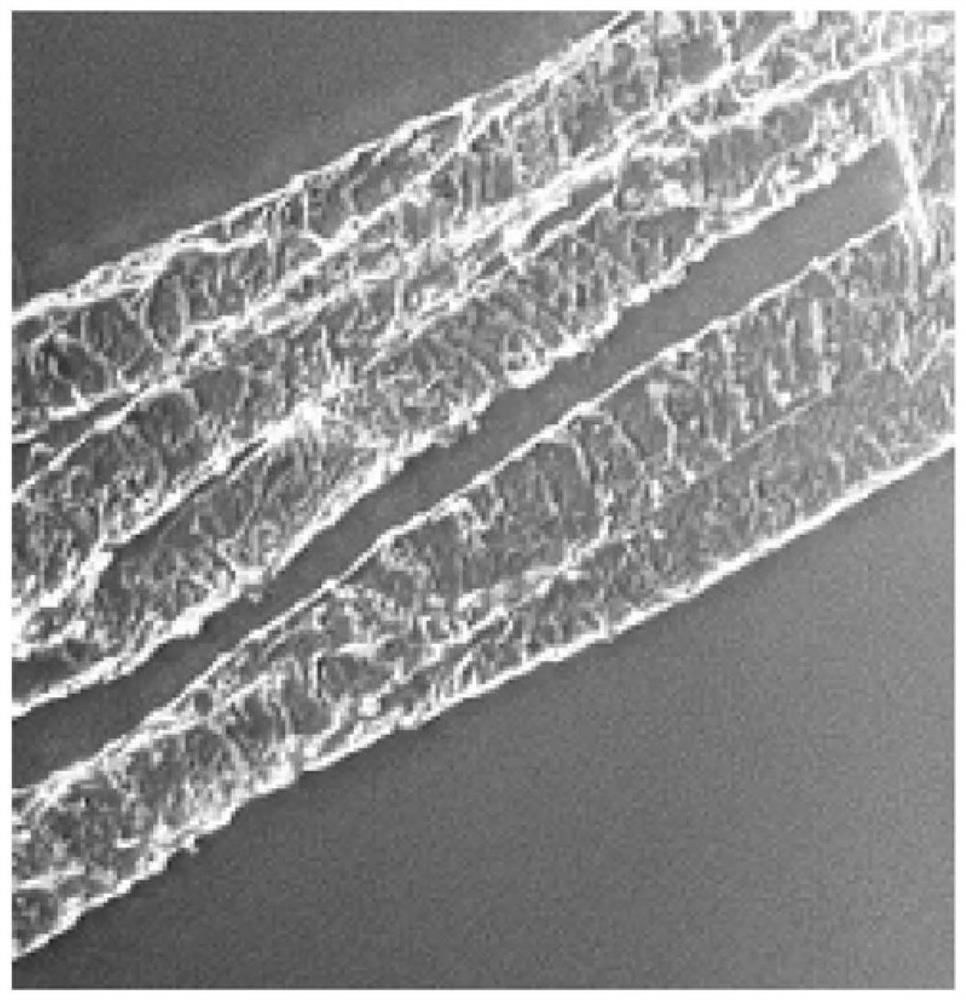

Method for producing Anti-shrinkage animal hair fibers

A manufacturing method and shrink-proof technology, which can be used in fiber processing, animal fibers, textiles and papermaking, etc., can solve problems such as hindering the practical application of liquid-liquid interface polymerization methods and hindering the formation of nylon and polymers, and achieve excellent shrinkage resistance. High performance and thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] The concentration of chloride ions contained in the wool fiber obtained in Example 1 was measured in accordance with the following method. According to JIS K 0127 chloride ion concentration, the wool sample was boiled in distilled water, and the extracted chloride ion was measured by ion chromatography. The measurement was carried out by the Environmental Materials Division of the Industrial Technology Center of "Aichi Center for Industry and Science Technology".

[0155] [table 5]

[0156] Chloride ion concentration (mg / L) measurement results

[0157]

[0158] (Example 1)

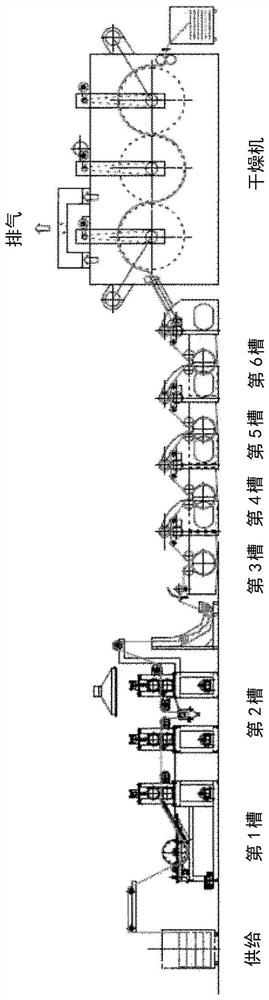

[0159] use figure 2 The shown apparatus continuously produces shrink-resistant animal hair fibers according to the following method.

[0160] The first process: at a running speed of 2m / min, put the well-washed wool top yarn ((Aust.MerinoWool Top 18.5μm) 25g / m, (one piece)) in the first bath in the first tank (including 0.2 mol / L of hexamethylenediamine, 0.2 mol / L of sodium hydroxide, and 1...

Embodiment 2

[0171] In addition to changing the concentration of hexamethylenediamine in the first bath to 0.1mol / L, changing the concentration of sodium hydroxide in the first bath to 0.1mol / L, and changing the concentration of sebacic acid dichloride in the second bath to Except that the concentration was changed to 0.1 mol / L, the production and evaluation of shrink-resistant animal hair fibers were performed by the same method as in Example 1.

Embodiment 3

[0173] In addition to changing the concentration of hexamethylenediamine in the first bath to 0.05mol / L, changing the concentration of sodium hydroxide in the first bath to 0.05mol / L, and changing the concentration of sebacic acid dichloride in the second bath to Except that the concentration was changed to 0.05 mol / L, the production and evaluation of shrink-resistant animal hair fibers were performed by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com