Carbon fiber composite material for reinforcing notebook computer shell and preparation method thereof

A notebook computer and composite material technology, applied in the field of composite materials, can solve the problems of large volume, reduced portability, and heavy weight of the reinforced shell, and achieve the effects of increased portability, good protection, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a carbon fiber composite material for reinforcing a notebook computer casing, comprising the following steps:

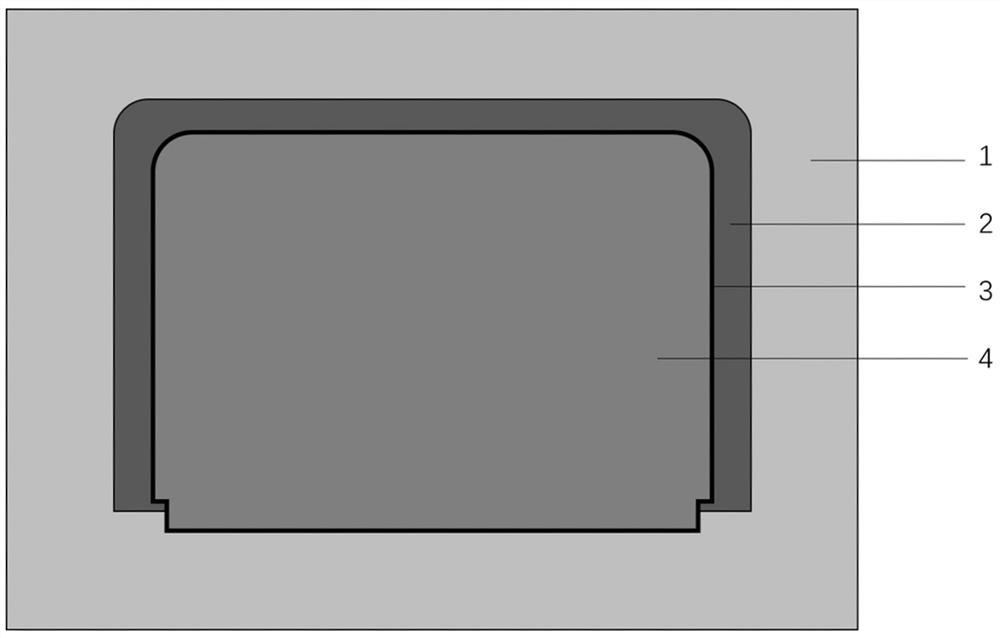

[0037]The notebook computer shell mold is divided into a hardening zone and a buffer zone, the hardening zone is the central part of the notebook computer shell mold, the buffer zone is the peripheral edge part of the notebook computer shell mold, the hardening zone and the buffer Die isolation boards are set between zones;

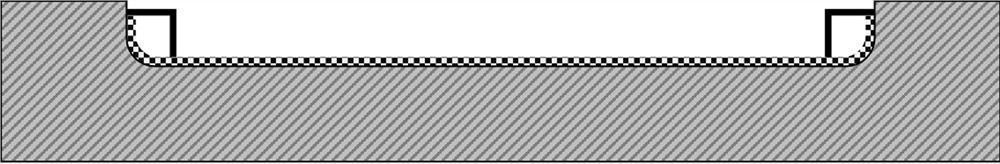

[0038] The carbon fiber cloth is laid flat in the notebook computer casing mold to obtain a mold for laying the carbon fiber cloth;

[0039] Mixing bisphenol A type diglycidyl ether prepolymer and amine curing agent, pouring in the hardening area, and then pre-curing to obtain the pre-curing hardening area;

[0040] After removing the mold isolation plate, apply a silane coupling agent at the interface between the hardening zone and the buffer zone;

[0041] Mix isocyanate and hydroxyl-termi...

Embodiment 1

[0066] Fiber laying: Cut T700 plain weave carbon fiber cloth according to the size of the mold (T700 carbon fiber cloth, the surface density is 198g / m 2 , with a thickness of 0.23mm), and lay 15 layers in the mold;

[0067] Casting in the hardening area: fully mix the bisphenol A diglycidyl ether prepolymer and the curing agent diethyltoluenediamine, the mixing mass ratio is 78 parts of T700 carbon fiber cloth, 18 parts of bisphenol A diglycidyl ether, two 6 parts of ethyltoluenediamine, poured in the hardening area, heated to 90°C, and continued for 60 minutes for pre-curing;

[0068] Remove the mold isolation plate between the hardening zone and the buffer zone, and apply silane coupling agent KH-570 on the interface between the hardening zone and the buffer zone, and the dosage of the silane coupling agent is 24mg / cm 2 ;

[0069] Dehydration treatment: Carry out dehydration treatment on dimethylene phenyl diisocyanate and hydroxyl-terminated isoprene respectively: heat to...

Embodiment 2

[0074] Fiber laying: Cut T700 plain weave carbon fiber cloth according to the size of the mold (T700 carbon fiber cloth, the surface density is 198g / m 2 , with a thickness of 0.23mm), and lay 10 layers in the mold;

[0075] Casting in the hardening area: fully mix the bisphenol A diglycidyl ether prepolymer and the curing agent diethyltoluenediamine, the mixing mass ratio is 82 parts of T700 carbon fiber cloth, 15 parts of bisphenol A diglycidyl ether, two 4 parts of ethyltoluenediamine, poured in the hardening area, heated to 90°C, and continued for 50 minutes for pre-curing;

[0076] Remove the mold isolation plate between the hardening zone and the buffer zone, and apply silane coupling agent KH-570 on the interface between the hardening zone and the buffer zone, and the dosage of the silane coupling agent is 24mg / cm 2 ;

[0077] Dehydration treatment: perform dehydration treatment on dimethylene phenyl diisocyanate and hydroxyl-terminated isoprene respectively: heat to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com