Expanded-flow hybrid dynamic polymer and method for realizing expanded-flow property thereof

A dilatant, polymer technology, applied in dilatant hybrid dynamic polymers and its realization of dilatancy, can solve the problems of lack of sacrificial components, short service life, waste of resources, etc., and achieve excellent comprehensive expansion. The effect of fluidity, high performance controllability, and fast dynamic transition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0914]In the preparation process of the polymer, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam it.

[0915] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the polymer to make it a uniform foam, and then through physical or Chemical changes shape it into foam. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0916] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the polymer, which includes but is not limited to the following methods: (1) inert gas foaming method, that is, under pressure Under normal circumstances, the inert gas is pressed into the molten polymer or pasty material, and then the pressure is reduced and the tem...

Embodiment 1

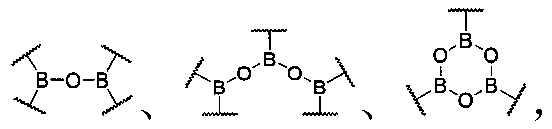

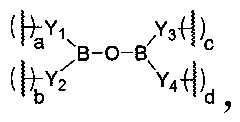

[0941]

[0942] Using pyridine as a catalyst and dichloromethane as a solvent, a dynamic crosslinking agent is prepared by reacting compound (a) with excess 4-vinylbenzoyl chloride; 110 molar equivalents of 1-(2-methylhexyl)- 4-vinylbenzene, 2 molar equivalents of dynamic cross-linking agent, 0.6 molar equivalents of benzoyl peroxide, placed in a reaction vessel, dissolved with an appropriate amount of toluene, stirred and reacted at 70°C for 24 hours under a nitrogen atmosphere to obtain a dynamic covalent Cross-linked polystyrene derivative. Take 60 molar equivalents of 1-(2-methylhexyl)-4-vinylbenzene, 50 molar equivalents of styrene, 6 molar equivalents of polyethylene glycol dimethacrylate (molecular weight is 1000), 0.6 molar equivalents of benzene peroxide Formyl, placed in a reaction vessel, record the total mass of the above reactants as 100wt%, then add 70wt% dynamically covalently cross-linked polystyrene derivatives, 300wt% dimethylformamide, stir and swell for ...

Embodiment 2

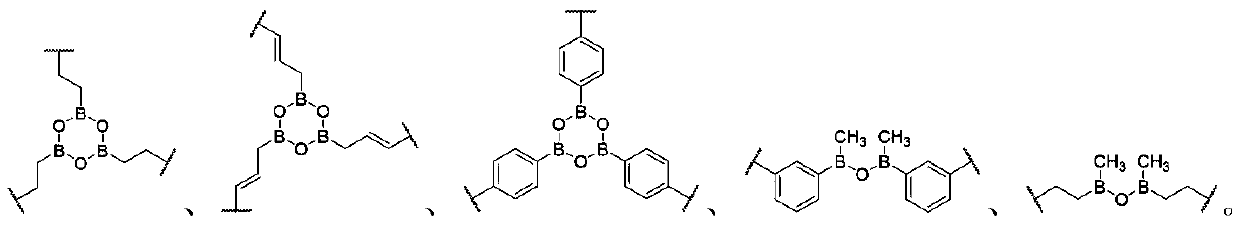

[0944]

[0945] Take 60 molar equivalents of 1-(2-methoxyethoxy)-4-vinylbenzene, 10 molar equivalents of compound (a), 10 molar equivalents of compound (b), 4 molar equivalents of N-(2-(4-vinyl Phenoxy)ethyl)acrylamide, 1.2 molar equivalents of divinylbenzene, placed in a reaction vessel, dissolved with an appropriate amount of toluene, added 0.4 molar equivalents of azobisisobutyronitrile, and stirred at 70°C for 24 hours under a nitrogen atmosphere , to prepare a dilatant polymer organogel. The gel had a tensile strength of 1.1 MPa and an elongation at break of 540%. The glass transition temperature of the dilatant gel is 52°C, and it also contains rich strong dynamic non-covalent interactions to obtain multiple dilation properties. It is made into a sample with a thickness of 2cm, according to EN1621-2012 method, the measured impact force of the sample passing through at 25°C is 19.9KN. The dilatant gel also has good tear resistance, and can be used in commodity packag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com