Pneumatic tyre

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc. to prevent cracks, maintain handling stability, and reduce air resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

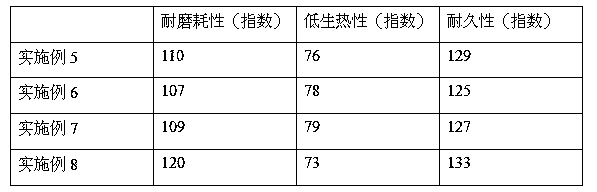

Embodiment 1

[0070] Weigh 50g of butadiene rubber, 4g of chlorinated butyl rubber, 3g of nitrile rubber, 3g of EPDM rubber and 4g of styrene-butadiene rubber, and then add 2g, 2g, 1g, 1g of 11N110, N22O, N330 and N326 respectively Carbon black, then add 4g of silane coupling agent, and finally add 3g of high styrene and 4g of reinforcing resin. Pneumatic tires are prepared through kneading, extrusion, calendering, cutting and molding vulcanization processes.

Embodiment 2

[0072] Weigh 45g of butadiene rubber, 5g of chlorinated butyl rubber, 5g of nitrile rubber, 4g of EPDM rubber and 4g of styrene-butadiene rubber, and then add 1g, 2g, 1g, 2g of 11N110, N22O, N330 and N326 respectively Carbon black, then add 5g of silane coupling agent, and finally add 4g of high styrene and 3g of reinforcing resin. Pneumatic tires are prepared through kneading, extrusion, calendering, cutting and molding vulcanization processes.

Embodiment 3

[0074] Weigh 60g of butadiene rubber, 4g of chlorinated butyl rubber, 4g of nitrile rubber, 3g of EPDM rubber and 3g of styrene-butadiene rubber, and then add 2g, 1g, 2g, 2g of 11N110, N22O, N330 and N326 respectively Carbon black, then add 5g of silane coupling agent, and finally add 3g of high styrene and 3g of reinforcing resin. Pneumatic tires are prepared through kneading, extrusion, calendering, cutting and molding vulcanization processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com