Glass-fiber membrane and glass-fiber vacuum bag

A technology of glass fiber film and glass fiber, applied in the field of composite film, can solve the problems of easy vacuum bag, loss of vacuum sealing effect, low strength, etc., and achieve the effect of improving the overall structural strength, improving connection stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

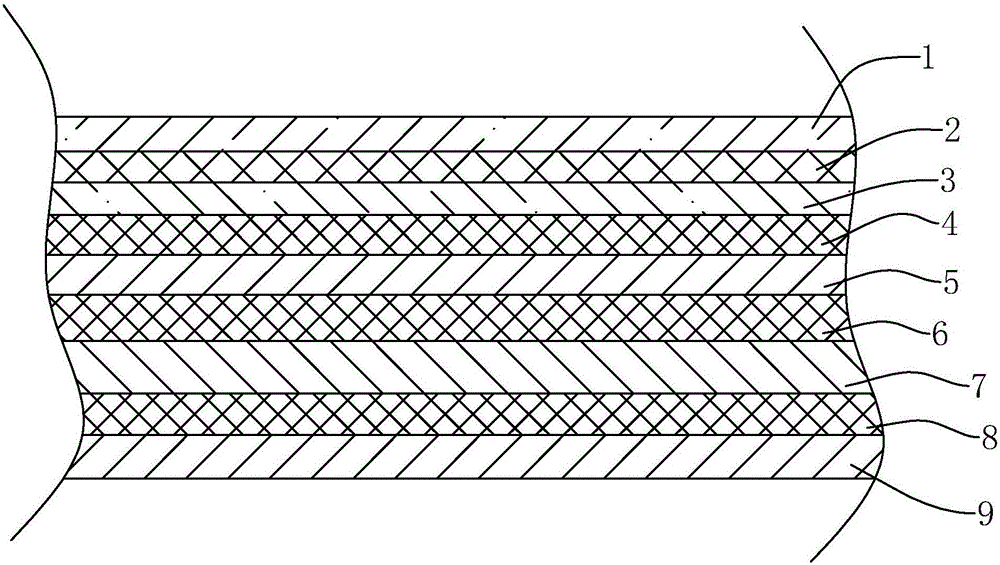

[0037] Embodiment 1: a kind of glass fiber membrane, such as figure 1 As shown, it includes glass fiber cloth layer 1, flame retardant adhesive layer 2, PET layer 3 (polyethylene terephthalate film), first adhesive layer 4, aluminum foil layer 5, The second adhesive layer 6, the PA layer 7 (nylon), the third adhesive layer 8 and the SPE layer 9 (super functional PE film) with a thickness of 65 μm.

[0038]Among them, the glass fiber cloth layer 1 is 110g / m; the thickness of the PET layer 3 and the PA layer 7 are both 15 μm, and the thickness of the aluminum foil layer 5 is 9 μm; the first adhesive layer 4, the second adhesive layer 6 and the second adhesive layer The three adhesive layers 8 are acrylic adhesive layer, methacrylic adhesive layer, acrylate adhesive layer, epoxy resin adhesive layer, polyurethane composite adhesive layer, methacrylate adhesive layer, silicone modified Any one of the acrylate adhesive layers, and different types of adhesive layers can also be use...

Embodiment 2

[0045] Embodiment 2: a glass fiber vacuum bag, a glass fiber vacuum bag made of the glass fiber film in embodiment 1.

Embodiment 3

[0046] Embodiment 3: a kind of glass fiber vacuum bag making process among making embodiment 2 comprises the following steps:

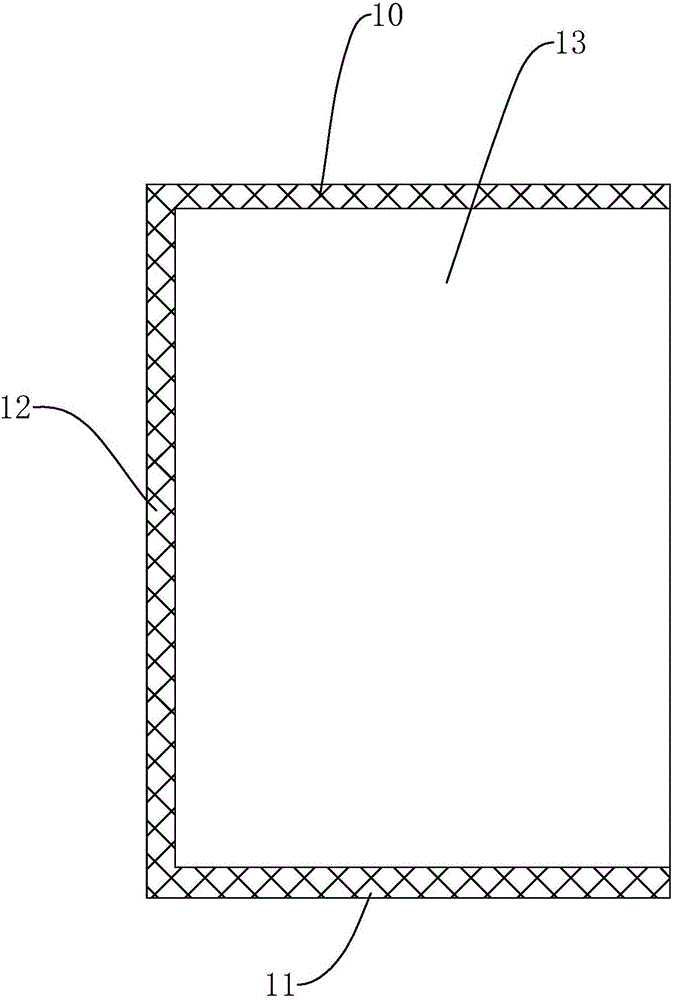

[0047] S1, combine figure 2 As shown, the glass fiber membrane is folded in half to form a bag-like opening with the upper side 10, the lower side 11 and the left side 12, and one side of the glass fiber cloth layer 1 is the outer surface of the glass fiber vacuum bag.

[0048] S2. Carry out thermal bonding of the segmented hot-pressing module to the lower side 11 of the bag sample. The heating of the segmented hot-pressing module is symmetrically set, and the temperature in the middle is higher than the temperature on both sides; this scheme adopts a five-segment module Thermal bonding, and the temperature range is 150°C to 250°C, that is, the temperature of the modules from left to right is 150°C, 200°C, 250°C, 200°C, and 150°C.

[0049] S3. Carry out hot-pressing bonding to the left side 12 of the bag sample, and the hot-pressing temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com