High-barrier multi-layer coextrusion functional packaging film with ultraviolet resistance effect

A multi-layer co-extrusion and high barrier technology, applied in the field of packaging materials, can solve the problems of solvent residue and achieve excellent anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

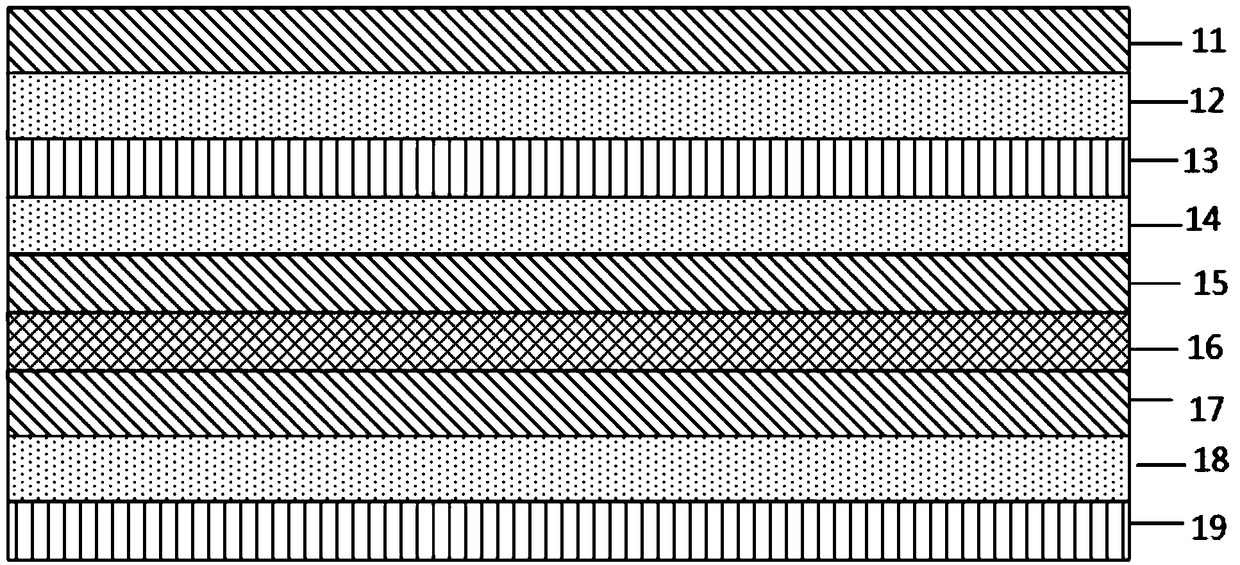

Image

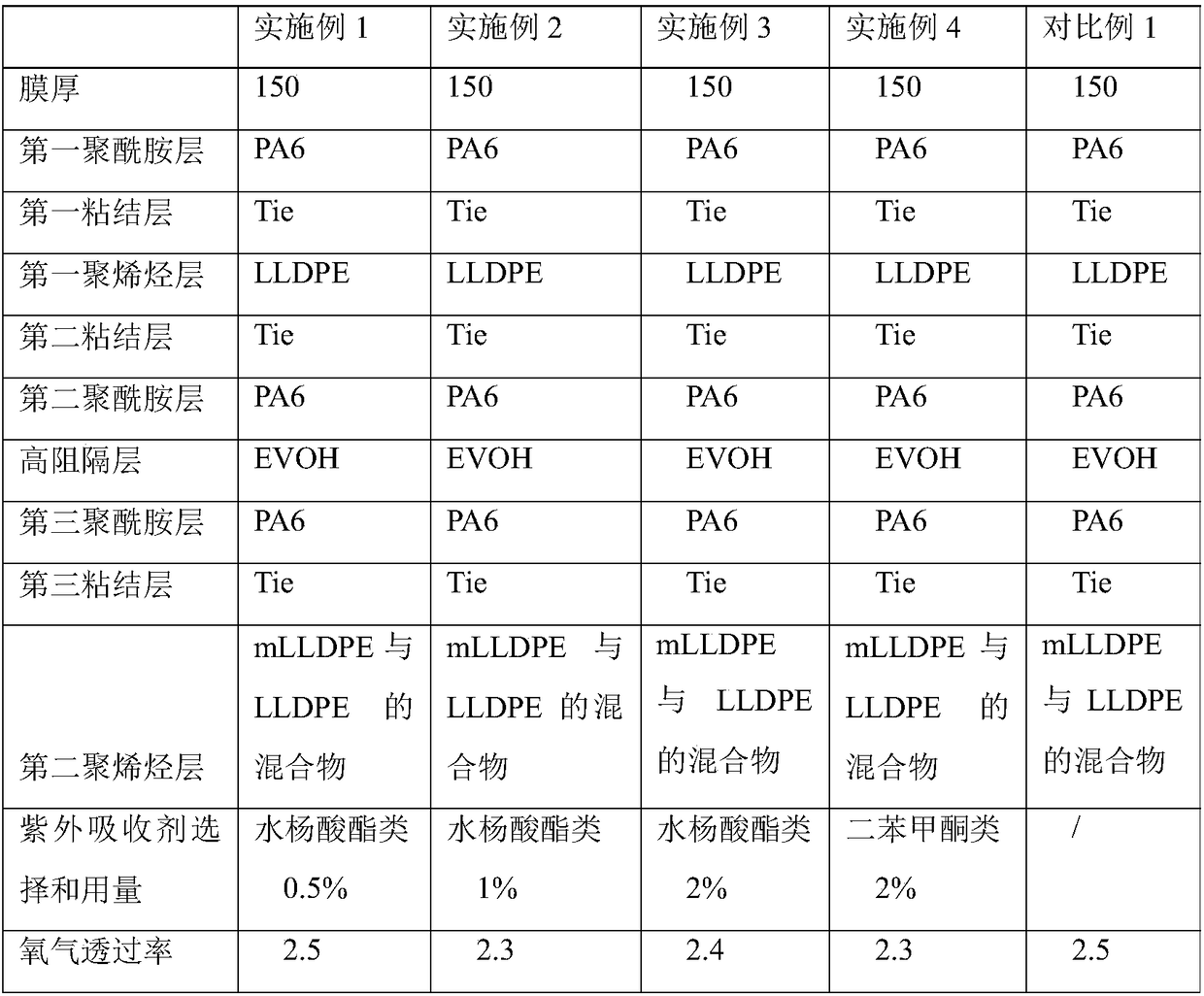

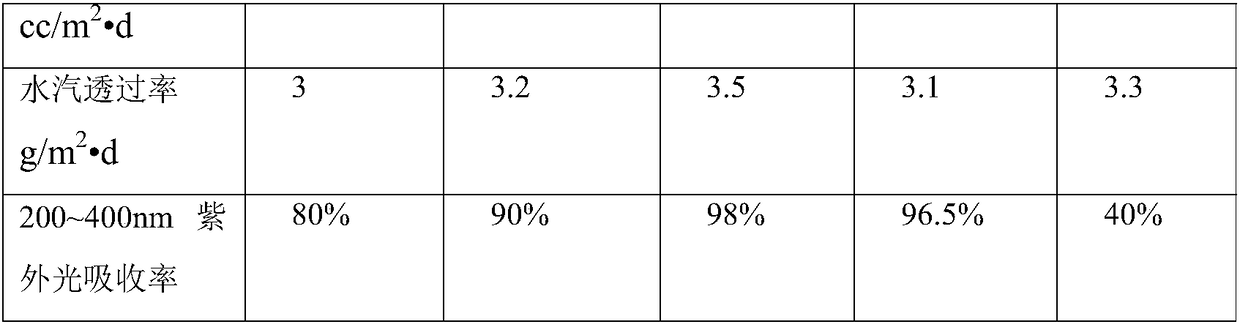

Examples

Embodiment 1

[0045] A preparation method of a high-barrier multilayer co-extruded functional packaging film with anti-ultraviolet effect, comprising the following steps:

[0046] 1) Feeding: Weighing type flow adjustment system and weighing type raw material proportioning system are adopted. At the same time, during the process of raw material configuration to entering the extruder, the mixed material is always kept in a continuous stirring state to ensure that the raw material is evenly mixed.

[0047] For the first polyamide layer, the raw polyamide is added to the hopper 1 of the extruder, melted at a temperature of 220-260°C, and enters the die;

[0048] For the first bonding layer, the raw material maleic anhydride-modified polyethylene (Tie) is added to the hopper 2 of the extruder, melted at a temperature of 195-220 ° C, and enters the die;

[0049] For the first polyolefin layer, the raw material polyethylene and the ultraviolet absorber are mixed and then put into the hopper 3 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com