Multi-layer structure buffer packaging product comprising waste foamed plastic and preparation as well as application thereof

A multi-layer structure and layer structure technology, applied in the direction of packaging, wrapping paper, layered products, etc., can solve the problems of low recovery rate, product brittleness, low quality, etc., and achieve resource and energy saving, environmental protection, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials: waste expanded polystyrene particles, density 0.03g / cm 3 , the particle diameter is between 0.3 mm and 0.5 mm. Adhesive is polyvinyl acetal, paper material is quantitative 300g / m 2 kraft cardboard.

[0030] Production steps:

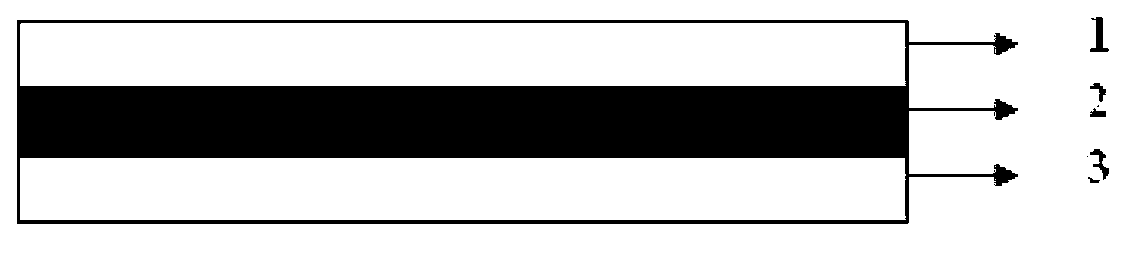

[0031] First, a polyvinyl acetal adhesive is sprayed on waste expanded polystyrene. Then, spread the waste polystyrene particles sprayed with the polyvinyl acetal binder solution evenly on a piece of kraft liner board, and then cover another piece of kraft liner board on the waste expanded polystyrene particles. Finally, at room temperature, the three-layer composite material was placed under a pressure of 20 kN / m, and after drying at room temperature, a three-layer composite material containing waste expanded polystyrene was obtained.

[0032] Product performance: The bonding strength of the three-layer structure composite product is 195.78N.

Embodiment 2

[0034] Raw materials: waste expanded polystyrene particles, density 0.03g / cm 3 , the particle diameter is between 0.3 mm and 0.5 mm. Adhesive is polyvinyl acetal, paper material is quantitative 300g / m 2 kraft liner board and basis weight 200g / m 2 of corrugated base paper.

[0035] Production steps:

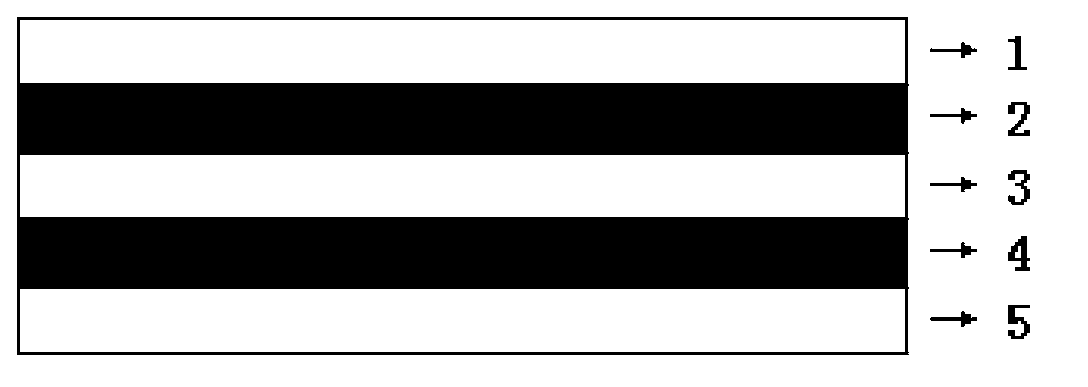

[0036] First, a polyvinyl acetal binder solution is sprayed on waste expanded polystyrene. Then, spread the waste polystyrene particles sprayed with polyvinyl acetal binder solution evenly on a piece of kraft cardboard, and then cover a layer of corrugated base paper on the waste expanded polystyrene particles. At normal temperature, the composite material with three-layer structure is placed under a pressure of 20 kN / m, and after drying at normal temperature, a composite material with three-layer structure including waste expanded polystyrene is obtained. On one side of the corrugated base paper of the three-layer structure composite material, a layer of waste expanded polys...

Embodiment 3

[0039] Raw materials: waste expanded polystyrene particles, density 0.03g / cm 3 , the particle diameter is between 0.3 mm and 0.5 mm. The adhesive is polyvinyl acetal, and the paper material is quantitative 250g / m 2 Flat pulp molded products.

[0040] Other steps are identical with embodiment 1.

[0041] Product performance: The bonding strength of the three-layer structure composite product is 2229.1N / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com