Edible mushroom cultivation material

A technology for culture material and edible fungi, applied in the field of culture material, can solve the problems of insufficient utilization of tea residues, environmental pollution, waste of resources, etc., and achieve the effects of being beneficial to environmental protection, reducing environmental pollution and saving wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment (utilize tea dregs to cultivate Pingru, Hericium erinaceus, fungus, fragrant fungus, Flammulina velutipes):

[0016] Choose fresh, clean tea dregs and crushed corn cobs for cultivation according to the following formula:

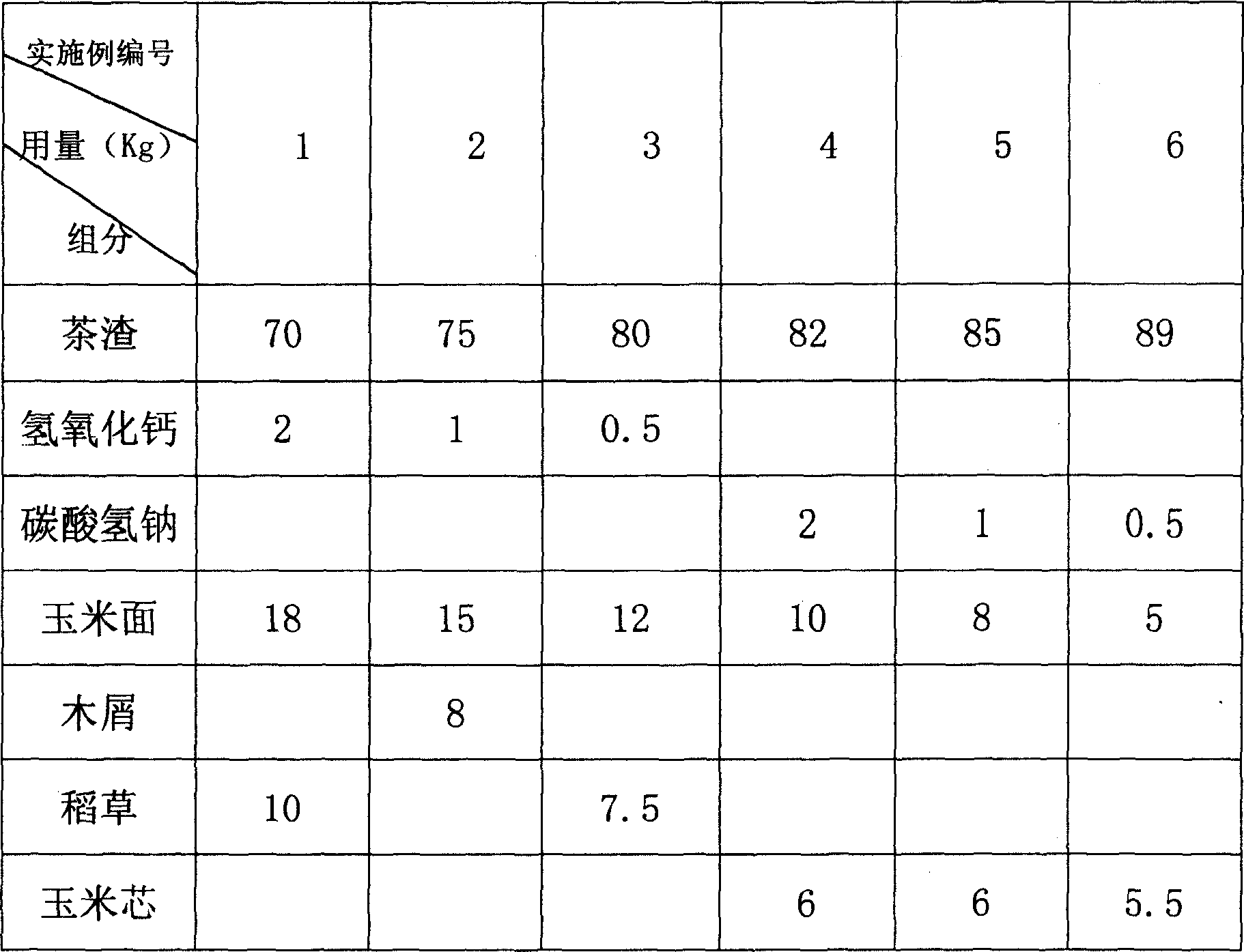

[0017] Formula 1: Composition and weight percentage of compost are: 70-89% of tea dregs, 0.5-2% of alkaline substances, 5-18% of cornmeal, 5-10% of sawdust, straw or / and pulverized corn cobs. Contain or add appropriate amount of water in this compost, with prior art; Concrete component and composition see the following table:

[0018]

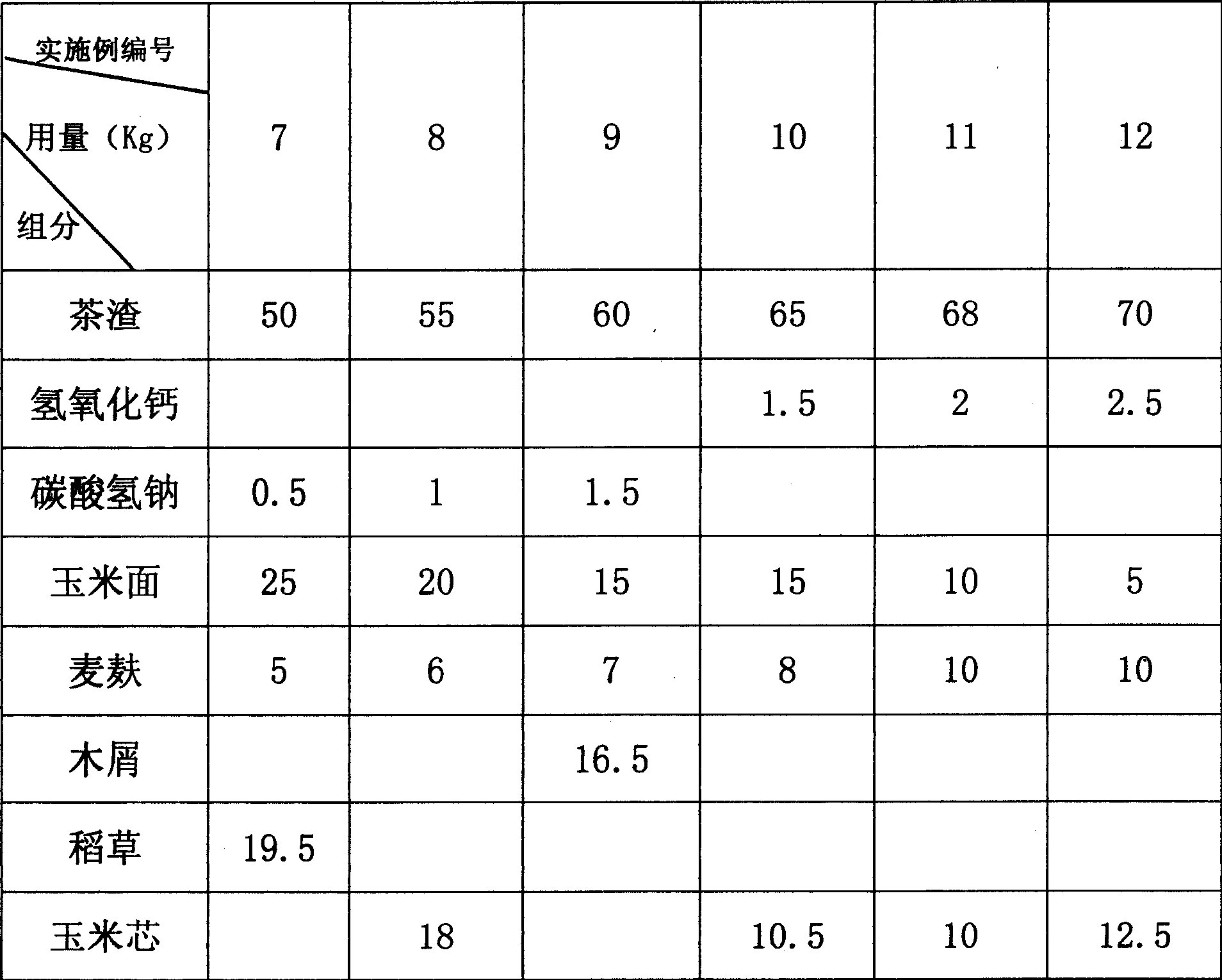

[0019] Formula 2: The compost composition and weight percentage are: 50-70% of tea dregs, 0.5-2.5% of alkaline substances, 5-25% of cornmeal, 5-10% of wheat bran, sawdust, straw or / and crushed corn cobs 5-20%. Contain or add appropriate amount of water in this compost, with prior art; Concrete component and composition see the following table:

[0020]

[0021] The original formula (comparison formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com