Super-wear-resistant coating for ground decoration and preparation method thereof

A ground decoration and ultra-wear-resistant technology, applied in the field of wear-resistant coatings, can solve the problems of large changes in curing time with temperature, high requirements for construction process control, and difficult anti-static functions, and achieve uniform anti-static performance, easy construction, and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

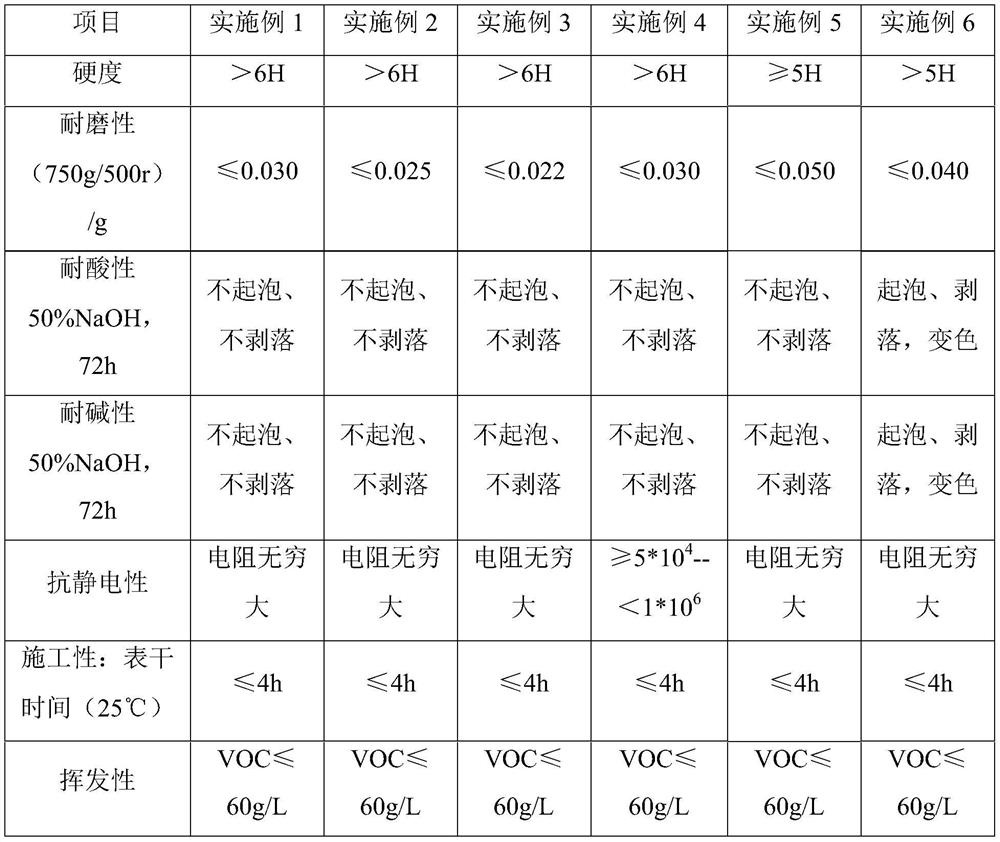

Examples

Embodiment 1

[0048] This embodiment provides a super wear-resistant paint for floor decoration, which is composed of A component and B component;

[0049] The A component is composed of the following components: epoxy resin, amino resin, alkyl glycidyl ether, filler, defoamer, leveling agent, silicon aluminum compound and color paste;

[0050] The B component is a modified amine curing agent;

[0051] In terms of parts by mass, the epoxy resin is 30 parts, the amino resin is 2 parts, the alkyl glycidyl ether is 3 parts, the filler is 15 parts, the defoamer is 0.3 parts, the leveling agent is 0.3 parts, silicon The aluminum compound is 10 parts, the color paste is 6 parts, and the modified amine curing agent is 15 parts.

Embodiment 2

[0053] This embodiment provides a super wear-resistant paint for floor decoration, which is composed of A component and B component;

[0054] The A component is composed of the following components: epoxy resin, amino resin, alkyl glycidyl ether, filler, defoamer, leveling agent, silicon aluminum compound and color paste;

[0055] The B component is a modified amine curing agent;

[0056] In parts by mass, the epoxy resin is 40 parts, the amino resin is 3 parts, the alkyl glycidyl ether is 4 parts, the filler is 20 parts, the defoamer is 0.6 parts, the leveling agent is 0.6 parts, silicon Aluminum compound is 15 parts, color paste is 8 parts, and modified amine curing agent is 20 parts.

Embodiment 3

[0058] This embodiment provides a super wear-resistant paint for floor decoration, which is composed of A component and B component;

[0059] The A component is composed of the following components: epoxy resin, amino resin, alkyl glycidyl ether, filler, defoamer, leveling agent, silicon aluminum compound and color paste;

[0060] The B component is a modified amine curing agent;

[0061] In parts by mass, the epoxy resin is 50 parts, the amino resin is 4 parts, the alkyl glycidyl ether is 5 parts, the filler is 25 parts, the defoamer is 0.8 part, the leveling agent is 0.8 part, silicon The aluminum compound is 20 parts, the color paste is 10 parts, and the modified amine curing agent is 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com