Antistatic master batches and preparation method and application thereof

A technology of antistatic masterbatch and antistatic agent, applied in the field of antistatic masterbatch and its preparation, can solve the problems of being easily adsorbed to the edge of the hopper, the color masterbatch becomes less, and the color of the product is unstable, and the surface is dust-proof. Good, stable product quality, the effect of improving the color difference problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a kind of antistatic masterbatch, the raw material formula of this antistatic masterbatch is as follows:

[0030] Antistatic agent 2%, carrier resin 96%, auxiliary agent 2%, wherein, antistatic agent is aliphatic amine polyoxyethylene ether, purchased from Kunshan Shixin Plastic Co., Ltd., brand name is RMPA000175; carrier resin is polypropylene resin, purchased from From SABIC company, the brand is PP575; the auxiliary agent is vinyl bis stearamide, purchased from Changshu Huibang New Material Co., Ltd., the brand is RMPA000092.

[0031] The following preparation method is used to prepare the antistatic masterbatch. The preparation method is to mix the antistatic agent, carrier resin and additives uniformly, add them to the screw extruder, melt and knead and extrude at 160-230°C, and cool After granulation and drying, the antistatic masterbatch is obtained.

[0032] The antistatic masterbatch prepared by the above method has milky white appear...

Embodiment 2

[0035] Embodiment 2 (application of antistatic masterbatch in injection molding products)

[0036] The antistatic masterbatch of Example 1 is applied to the production of scissor handles.

[0037] The raw material formula of the scissors handle is 1kg of antistatic masterbatch, 1kg of color masterbatch, 15.5kg of polypropylene resin, and 7.5kg of calcium carbonate. The above raw materials are mixed and injection molded to make scissors handle. The above-mentioned medium color masterbatch is purchased from Kunshan Shixin Plastic Co., Ltd., the trademark is RMPA000805.

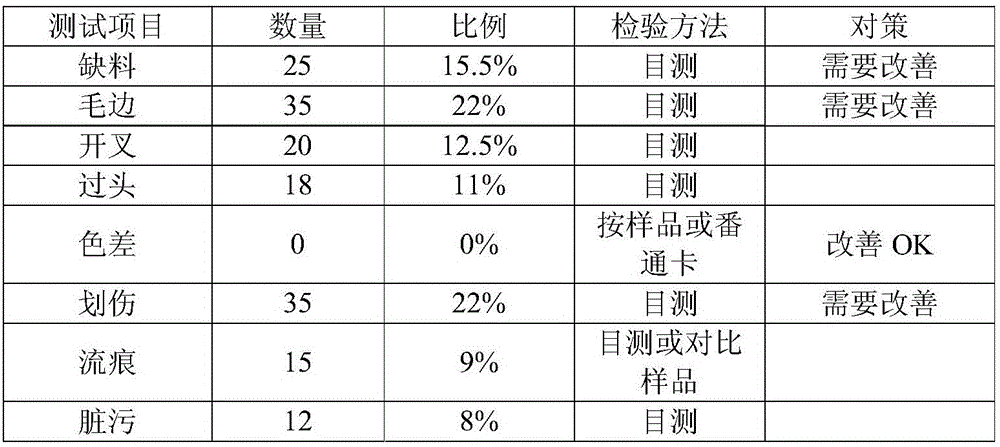

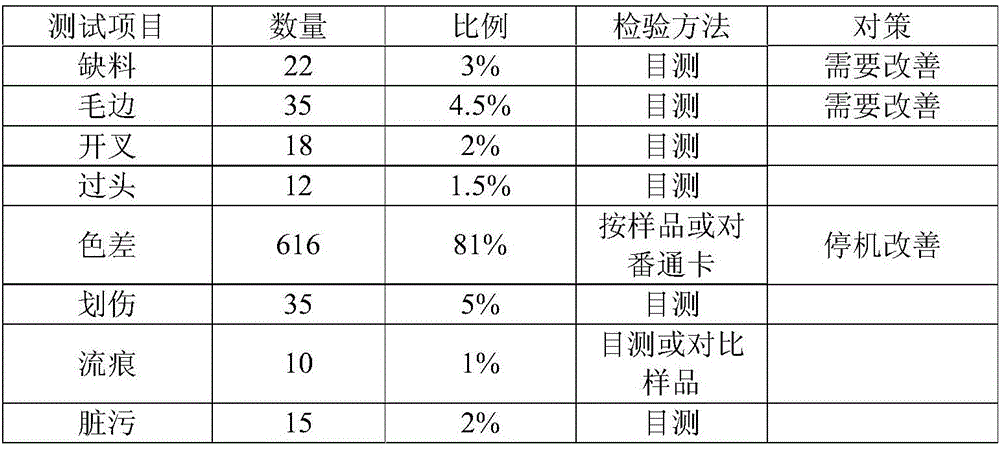

[0038] The results of scissors handles produced using the above raw materials are shown in Table 2.

[0039] Table 2 is the production situation of the handle of scissors of embodiment 2

[0040]

[0041] The above results show that the scissors handle produced by using the antistatic masterbatch of the present invention has no color difference in product color, stable quality, and a color difference ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com