Sheet packaging apparatus

a technology of packaging apparatus and sheets, which is applied in the direction of packaging goods, tray containers, containers, etc., can solve the problems of difficult to accurately cut the connecting members, lack of versatility to use packs of different thicknesses, and difficult to use packaging of each corner of the pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

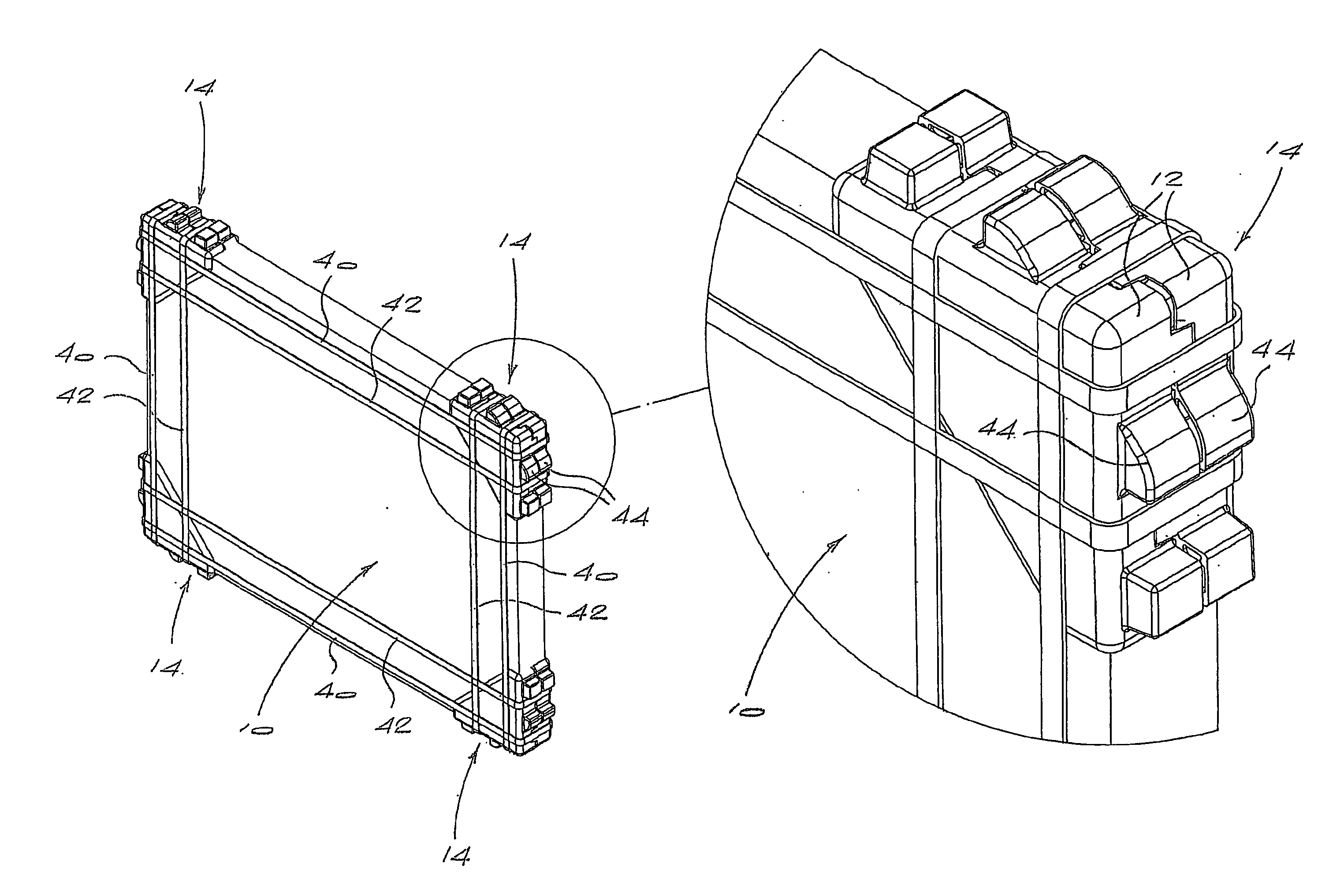

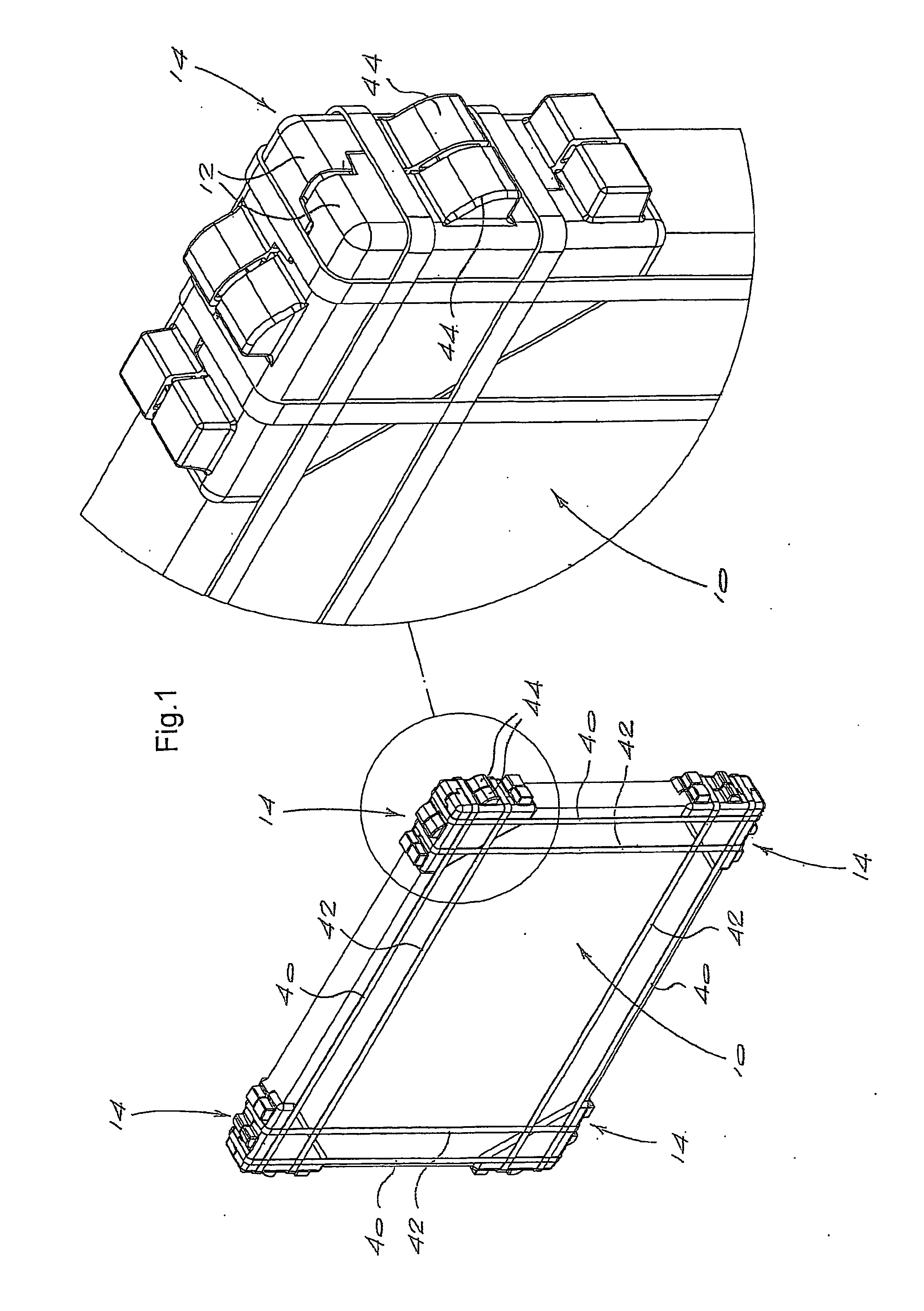

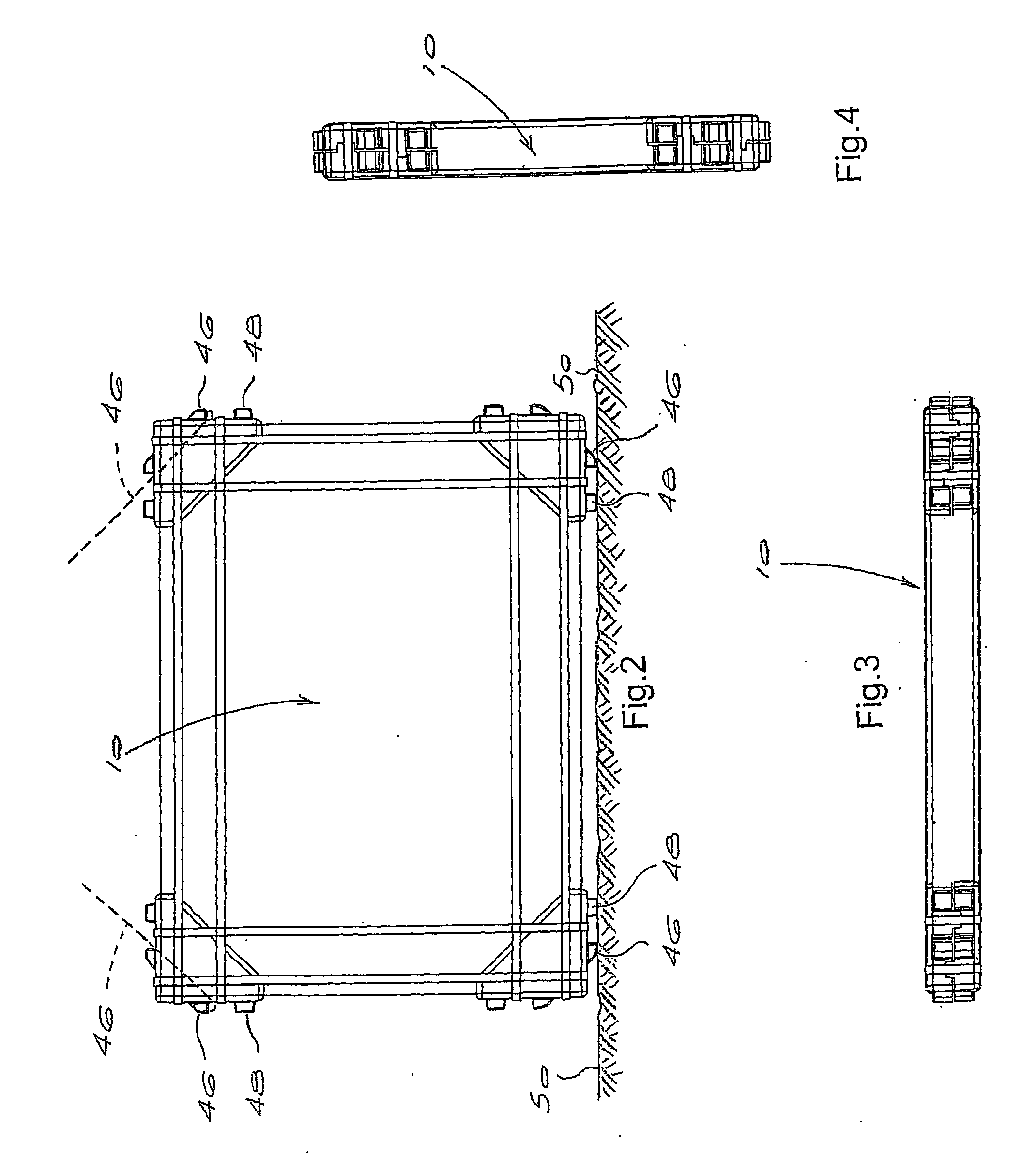

[0026] As described hereunder the invention is concerned with the packaging of a stack of glass sheets arranged in a polygonal, in this case rectangular, pack 10.

[0027] Reference is made firstly to FIGS. 5, 6 and 7 which illustrate a single packaging member 12 of a corner packaging device 14, one such corner packaging device 14 being provided for each corner of the pack 10. The packaging member 12 is moulded in one piece of a suitably robust plastics material and includes a generally triangular facing element 16 having a ribbed inner surface 18 and a flat outer surface 20. The member 12 also includes a pair of generally planar flanges 22 which meet one another at a corner 24 of the facing element and which extend transversely to the facing element.

[0028] As shown in FIG. 8, each flange has an inner edge 26. Extending beyond this edge, in the plane of the flange, is a projection 28. Spaced from the projection 28 is a recess 30 which extends into the flange from the inner edge 26. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com