Full-biodegradable mulching film with controllable degradation period and preparation method thereof

A technology of degrading mulch film and degradation cycle, applied in the fields of botanical equipment and methods, plant protection, plant protection cover, etc. Excellent water vapor barrier properties, improved mechanical properties, and improved moisture retention properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

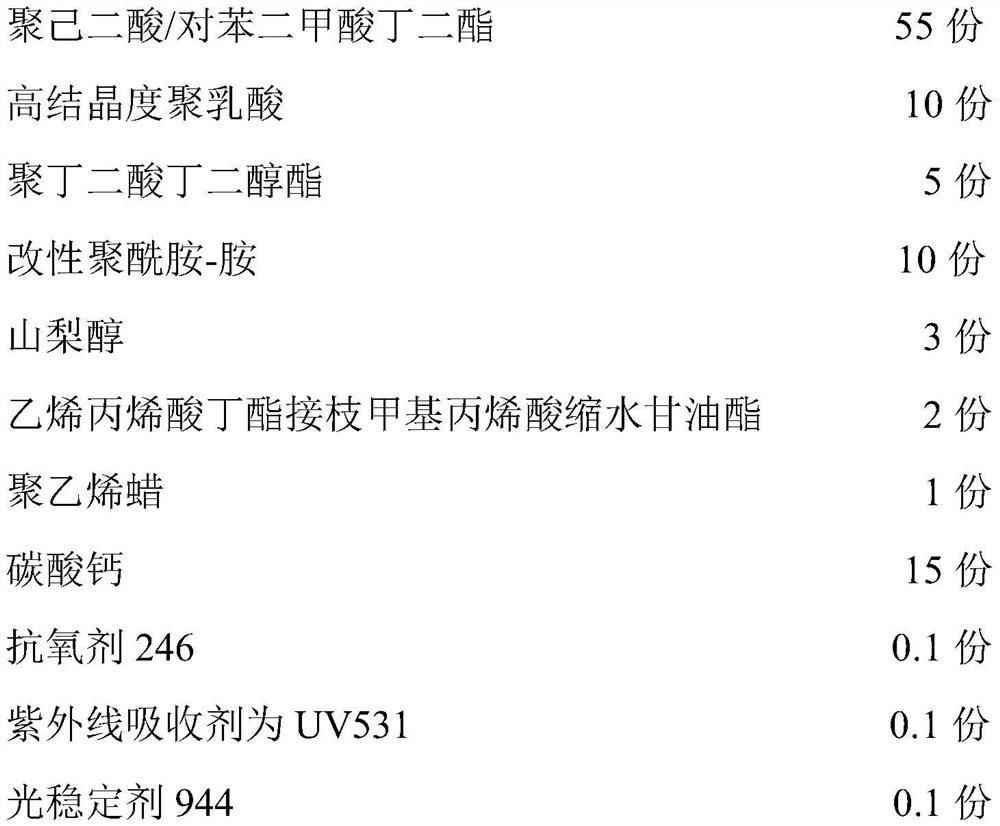

[0031] This embodiment provides a fully biodegradable mulch film with controllable degradation cycle. The raw materials include the following components in parts by weight:

[0032]

[0033] The preparation method comprises steps:

[0034] (1) Polybutylene adipate / terephthalate, high crystallinity polylactic acid, polybutylene succinate, modified polyamidoamine, sorbitol, polyethylene wax and ethylene butyl acrylate The grafted glycidyl methacrylate is stirred and mixed evenly, then calcium carbonate, antioxidant 246, ultraviolet absorber is UV531 and light stabilizer 944 are added, and stirring is continued for 5 minutes to obtain a mixture;

[0035] (2) The mixed material is melted and blended and extruded by a parallel reverse twin-screw extruder to obtain a modified material;

[0036] (3) The obtained modified material was blown into film at 175° C. by a film blowing machine to obtain a fully biodegradable mulch film with a thickness of 10 μm and a controllable period....

Embodiment 2

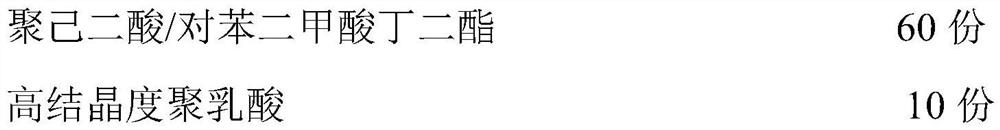

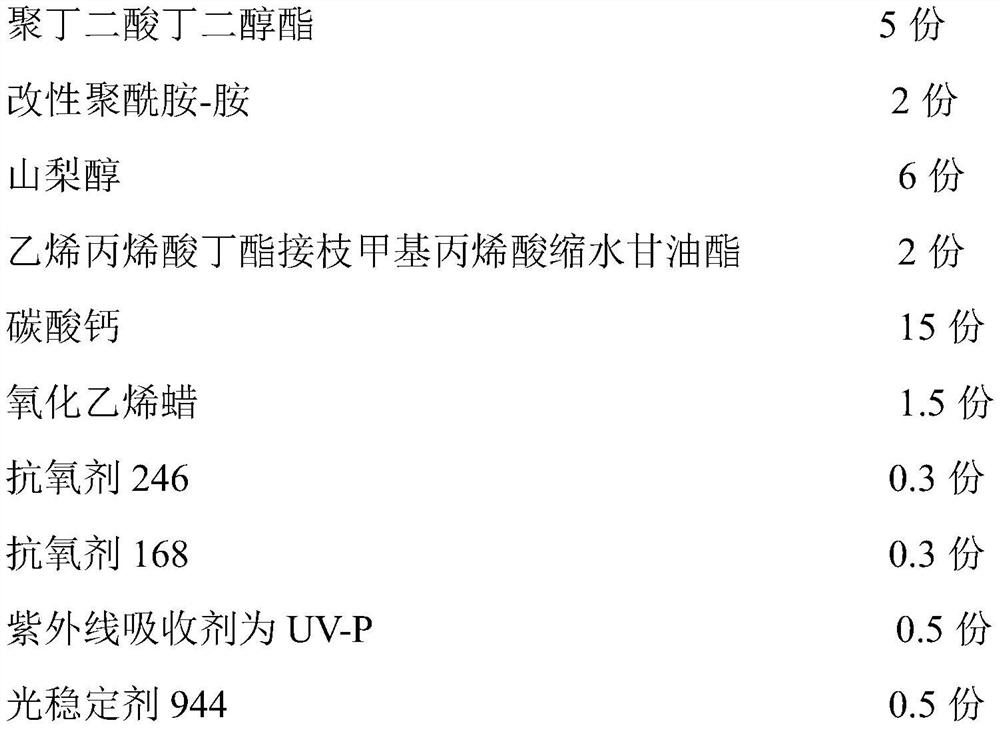

[0039] This embodiment provides a fully biodegradable mulch film with controllable degradation cycle. The raw materials include the following components in parts by weight:

[0040]

[0041]

[0042] The preparation method comprises steps:

[0043] (1) Polybutylene adipate / terephthalate, high crystallinity polylactic acid, polybutylene succinate, modified polyamide-amine, sorbitol, ethylene oxide wax and ethylene butyl acrylate Stir and mix the grafted glycidyl methacrylate evenly, then add calcium carbonate, antioxidant 246, antioxidant 168, ultraviolet absorber UV-P and light stabilizer 944, and continue stirring for 5 minutes to obtain a mixture;

[0044] (2) The mixed material is melted and blended and extruded by a parallel reverse twin-screw extruder to obtain a modified material;

[0045] (3) The obtained modified material was blown into film at 175° C. by a film blowing machine to obtain a fully biodegradable mulch film with a thickness of 10 μm and a controllable...

Embodiment 3

[0048] This embodiment provides a fully biodegradable mulch film with controllable degradation cycle. The raw materials include the following components in parts by weight:

[0049]

[0050]

[0051] The preparation method comprises steps:

[0052] (1) React ethylene bisstearamide, titanium salt and 1 / 2 ethylene oxide wax at 80°C for 40 minutes, regulator, and set aside;

[0053] (2) Polybutylene adipate / terephthalate, high crystallinity polylactic acid, polybutylene succinate, modified polyamide-amine, polyglycerol, ethylene oxide wax and ethylene butyl acrylate Stir and mix the grafted glycidyl methacrylate evenly, then add calcium carbonate, antioxidant 246, antioxidant 1076, ultraviolet absorber 234 and light stabilizer 770, and continue stirring for 5 minutes to obtain a mixture;

[0054] (3) The mixed material is melted and blended and extruded by a parallel reverse twin-screw extruder to obtain a modified material;

[0055] (4) The obtained modified material was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com