Water-blocking enhanced degradable antibacterial film as well as preparation method and application thereof

An enhanced, antibacterial film technology for sustainable manufacturing/processing, climate sustainability, sustainable packaging, etc., that solves problems such as short shelf life, failure to meet requirements to reduce plastic use, and no active additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

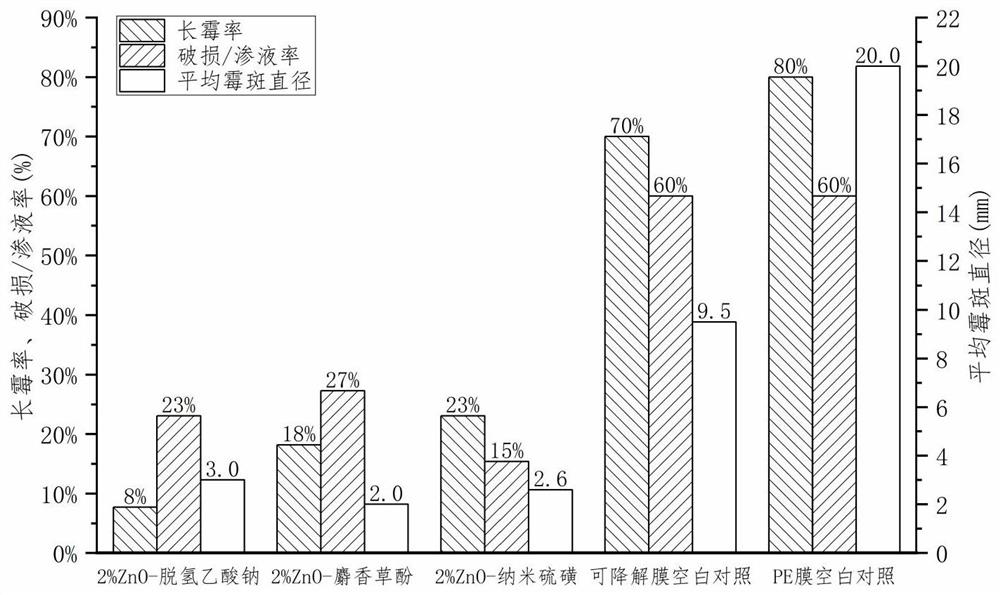

Embodiment 1

[0041] A degradable antibacterial film with enhanced water resistance, the inner layer is PLA and PBAT modified by composite antibacterial agent nano-zinc oxide-nano-sulfur, and the outer layer is coated with a layer of nano-SiO 2 , stearic acid, glutaraldehyde modified water-resistant barrier PVA coating sol, the specific steps of its preparation are as follows, including the following steps:

[0042] The first step is to weigh the raw materials of the composite antibacterial agent: 10g of nano zinc oxide of 30nm, 0.2g of titanate coupling agent TC-1140.2g, 10ml of isopropanol, and 10g of the second antibacterial agent are weighed according to the ratio of parts by mass. The second antibacterial agent is the nanometer sulfur of 50nm;

[0043] The second step: take 10g of nano-zinc oxide and place it in a vacuum drying oven, and fully dry it at 60°C for 12 hours;

[0044] Step 3: Take 0.2g of titanate coupling agent TC-114 and drop it into 10ml of isopropanol, heat to 50°C an...

Embodiment 2

[0061] A water blocking enhanced degradable antibacterial film, the inner layer is PLA and PBAT modified by antibacterial agent nano-zinc oxide-sodium dehydroacetate, and the outer layer is coated with a layer of nano-SiO 2 , stearic acid, glutaraldehyde modified water-resistant barrier PVA coating sol, the specific steps of its preparation are as follows:

[0062] The first step is to weigh the raw materials of the composite antibacterial agent: weigh 10g of nano-zinc oxide of 10-50nm, 0.3g of titanate coupling agent TC-1140.3g, 10ml of isopropanol, and the second antibacterial agent Sodium hydroacetate 10g;

[0063] Step 2: Take 10g of nano-zinc oxide and put it in a vacuum drying oven, and fully dry it at 60°C for 12 hours;

[0064] Step 3: Take 0.3g of titanate coupling agent TC-114 and drop into 10ml of isopropanol, heat to 50°C and stir, fully mix and dissolve;

[0065] Step 4: Take 10g of dried nano-zinc oxide and add it to the titanate coupling agent solution, stir e...

Embodiment 3

[0081] A degradable antibacterial film with enhanced water resistance, the inner layer is PLA and PBAT modified by the antibacterial agent nano-zinc oxide-thymol, and the outer layer is coated with a layer of nano-SiO 2 , stearic acid, glutaraldehyde modified water-resistant barrier PVA coating sol, the specific steps of its preparation are as follows:

[0082] The first step is to weigh the raw materials of the composite antibacterial agent: 10g of nano zinc oxide of 30nm, 0.2g of titanate coupling agent TC-1140.2g, 10ml of isopropanol, and 10g of the second antibacterial agent are weighed according to the ratio of parts by mass. The second antibacterial agent is Thymol;

[0083] Step 2: Take 10g of nano-zinc oxide and put it in a vacuum drying oven, and fully dry it at 60°C for 12 hours;

[0084] Step 3: Take 0.2g of titanate coupling agent TC-114 and drop it into 10ml of isopropanol, heat to 50°C and stir, fully mix and dissolve;

[0085] Step 4: Take 10g of dried nano-zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com