Palm leaf sheath fiber powder modified polyadipic acid/butylene terephthalate composite material and preparation method thereof

A technology of butylene terephthalate and palm leaf sheath, which is applied in the field of polymer composite materials, can solve the problems of high cost and insufficient tensile strength, and achieve the effects of reducing interface resistance, shortening the degradation cycle and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

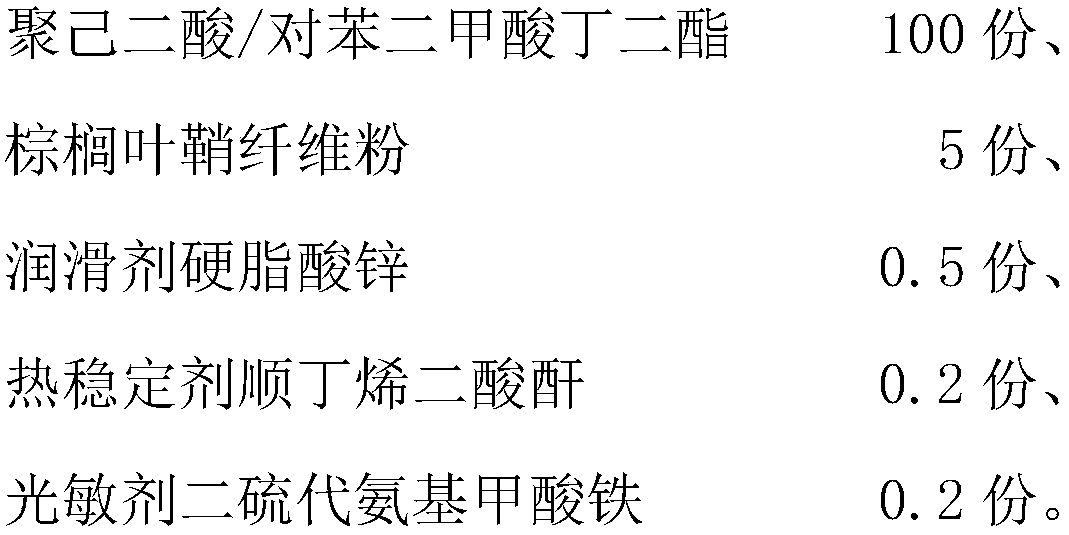

[0030] A modified polyadipate / butylene terephthalate composite material containing palm leaf sheath fiber powder and a preparation method thereof, calculated in parts by mass, its composition and content are as follows:

[0031]

[0032] Above-mentioned formula reacts according to the following steps:

[0033] (1) Place the dried palm leaf sheaths in a grinder and pulverize them into small pieces, then use a ball mill to grind them into powder, pass through a 100-mesh sieve to obtain powdery palm leaf sheaths, and then place them in a vacuum oven at 80°C for drying;

[0034] (2) Immerse the powdered palm leaf sheath in lye with a mass concentration of 4% (mixing ratio of solid to liquid mass: 1:20), treat it at 25°C for 2 hours, wash out the alkali with water, remove the alkali in an acid bath, and wash with water until neutral , after drying, palm leaf sheath fiber powder is obtained for subsequent use;

[0035] (3) the above-mentioned palm leaf sheath fiber powder is pla...

Embodiment 2

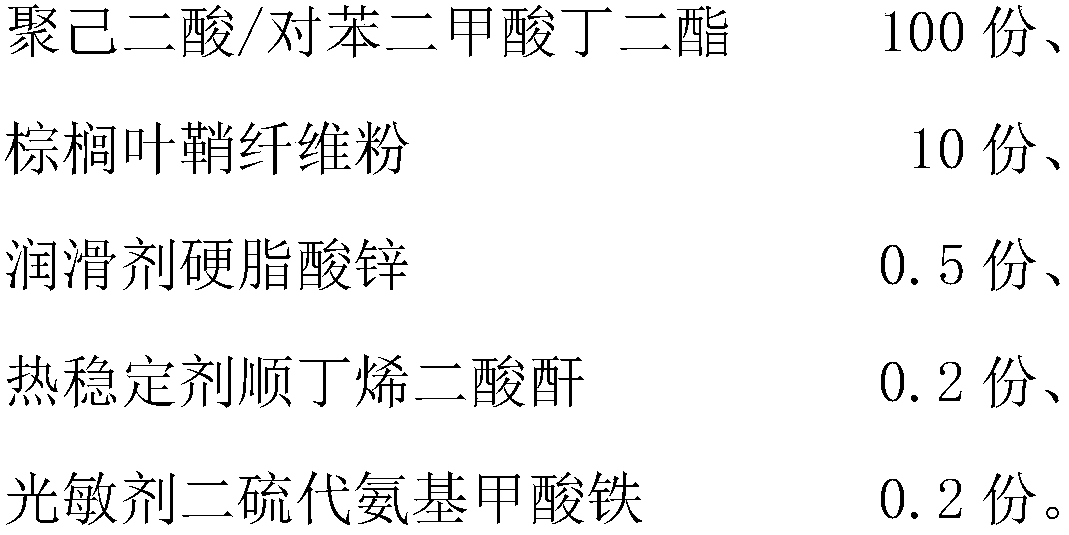

[0039] A modified polyadipate / butylene terephthalate composite material containing palm leaf sheath fiber powder and a preparation method thereof, calculated in parts by mass, its composition and content are as follows:

[0040]

[0041] Above-mentioned formula reacts according to the following steps:

[0042] (1) Place the dried palm leaf sheaths in a grinder and pulverize them into small pieces, then use a ball mill to grind them into powder, pass through a 100-mesh sieve to obtain powdery palm leaf sheaths, and then place them in a vacuum oven at 80°C for drying;

[0043] (2) Immerse the powdery palm leaf sheath in lye with a mass concentration of 3% (mixing ratio of solid to liquid mass: 1:20), treat it at 25°C for 3 hours, wash it with water to remove the alkali, acid bath, and wash to neutrality , after drying, palm leaf sheath fiber powder is obtained for subsequent use;

[0044] (3) the above-mentioned palm leaf sheath fiber powder is placed in a high-speed blender...

Embodiment 3

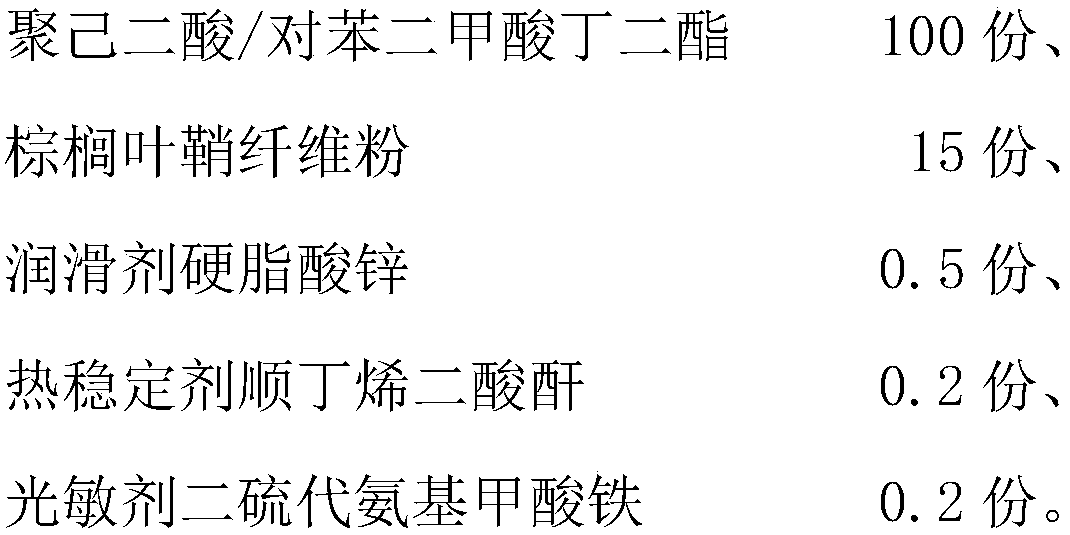

[0048] A modified polyadipate / butylene terephthalate composite material containing palm leaf sheath fiber powder and a preparation method thereof, calculated in parts by mass, its composition and content are as follows:

[0049]

[0050] Above-mentioned formula reacts according to the following steps:

[0051] (1) Place the dried palm leaf sheaths in a grinder and pulverize them into small pieces, then use a ball mill to grind them into powder, pass through a 100-mesh sieve to obtain powdery palm leaf sheaths, and then place them in a vacuum oven at 80°C for drying;

[0052] (2) Immerse the powdery palm leaf sheath in lye with a mass concentration of 2.5% (mixing ratio of solid to liquid mass: 1:20), treat it at 25°C for 3 hours, wash out the alkali with water, remove the alkali in an acid bath, and wash with water until neutral , after drying, palm leaf sheath fiber powder is obtained for subsequent use;

[0053](3) the above-mentioned palm leaf sheath fiber powder is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com