Preparation method for degradable polylactic acid-glycolic acid/polycaprolactone/I-type collagen electrospun fiber membrane material

A technology of glycolic acid and polycaprolactone, which is applied in the direction of cellulose/protein conjugated artificial filaments, textiles and papermaking, conjugated synthetic polymer artificial filaments, etc. Biological activity and other issues, to achieve the effect of short degradation cycle, improved repair effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

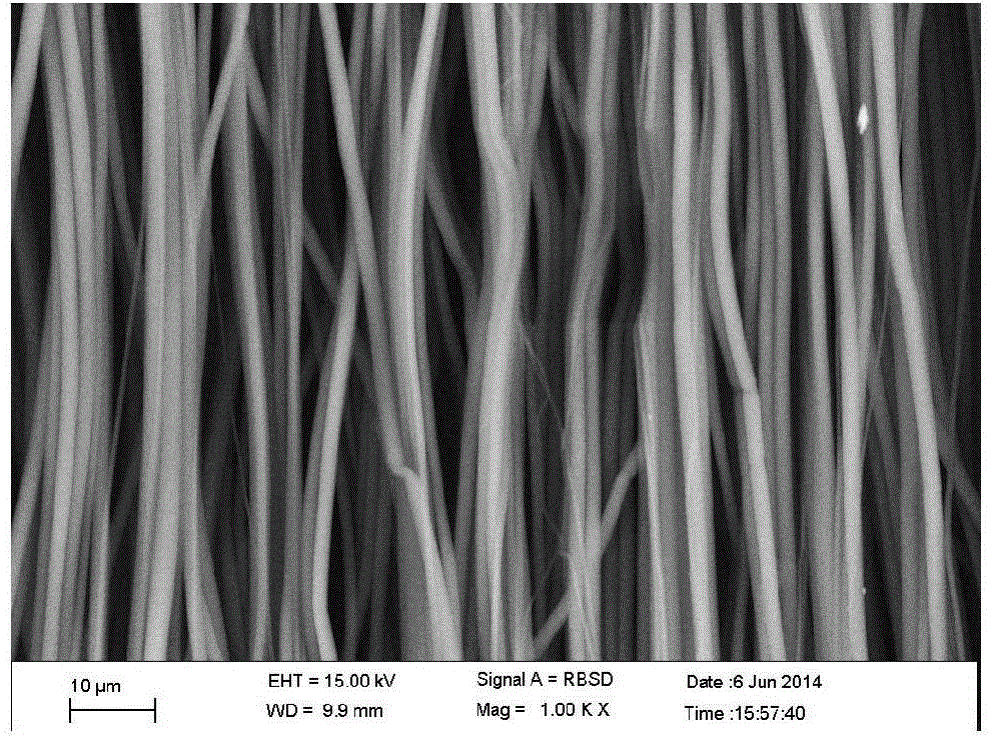

[0029] Cut polylactic acid-glycolic acid and polycaprolactone with a number average molecular weight of 110,000 into pieces, dissolve them in trifluoroethanol at a mass ratio of 1:1, and prepare a solution with a mass fraction of 8%, and then pour into the solution Add 0.5ml of 5mg / ml type I collagen solution, mix well, add the solution into the glass syringe, extrude through the propulsion device, the supply volume is 0.8mL / h, the electrospinning voltage is 15kV, the distance is 20cm, and the rotating cylinder The receiving device was set at a rotating speed of 3000rpm, and received continuously for 10 hours to obtain a 0.4mm thick electrospun fiber membrane with an average fiber diameter of 560nm and an electrospun fiber orientation rate of about 70%.

[0030] Scanning electron micrographs of the fibrous membrane as figure 1 shown.

Embodiment 2

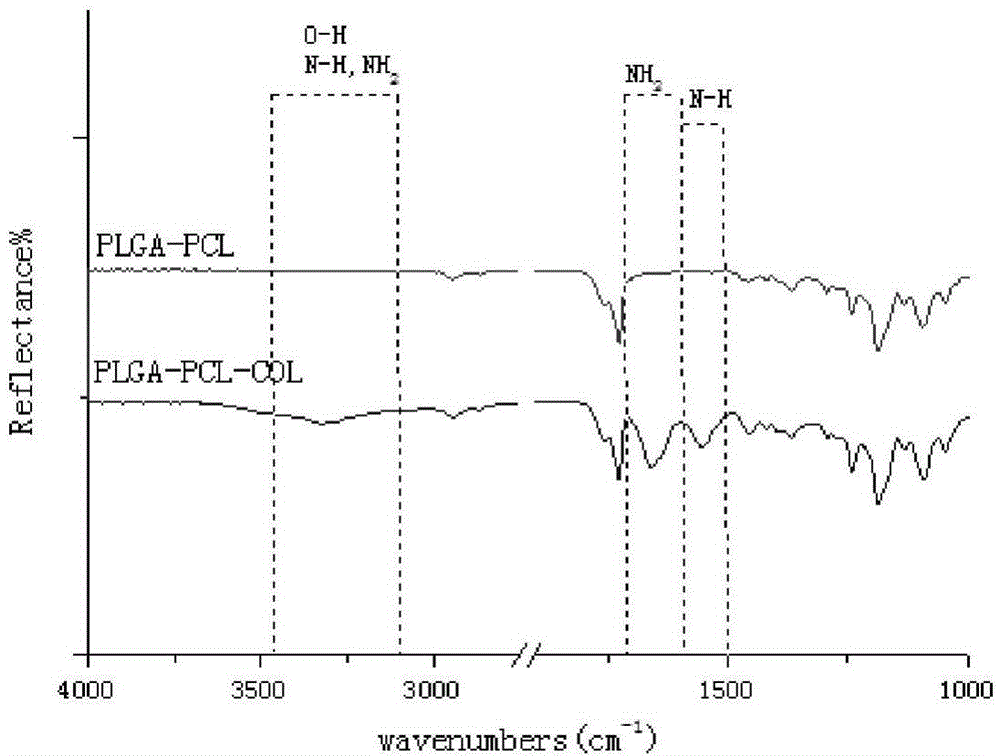

[0032] Shred polylactic acid-glycolic acid and polycaprolactone with a number average molecular weight of 110,000, dissolve them in trifluoroethanol at a mass ratio of 1:1, prepare a solution with a mass fraction of 12%, and then add 1ml of 5mg / ml type I collagen solution, after fully mixing, add the solution into the glass syringe, extrude through the propulsion device, the supply volume is 0.5mL / h, the electrospinning voltage is 15kV, the receiving distance is 20cm, and the drum receives The rotation speed of the device was set at 2400rpm, and the receiving was continued for 7 hours. Finally, a layer of electrospun fiber membrane with a thickness of about 0.45mm was obtained, the average fiber diameter was 600nm, and the orientation rate of the electrospun fiber was about 75%. Put it in a vacuum drying oven for 48 hours, detect its spectral distribution with an infrared spectrometer, and compare it with the electrospun membrane of polylactic acid-glycolic acid / polycaprolacton...

Embodiment 3

[0035] Shred polylactic acid-glycolic acid and polycaprolactone with a number average molecular weight of 110,000, dissolve them in trifluoroethanol at a mass ratio of 1:1, prepare a solution with a mass fraction of 15%, and then add 1ml of 5mg / ml type I collagen solution, after fully mixing, add the solution into the glass syringe, extrude through the propulsion device, the supply volume is 0.4mL / h, the electrospinning voltage is 15kV, the receiving distance is 20cm, and the rotating cylinder receives The rotation speed of the device was set at 2100rpm, and the receiving was continued for 5 hours. Finally, a layer of electrospun fiber membrane with a thickness of about 0.4mm was obtained, the average fiber diameter was 860nm, and the orientation rate of the electrospun fiber was about 80%. Mouse adipose stem cells were inoculated on the surface of the material.

[0036] attached image 3It is a polylactic acid-glycolic acid / polycaprolactone / type I collagen electrospun fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com