Application of food-grade microorganism in degradation of zearalenone

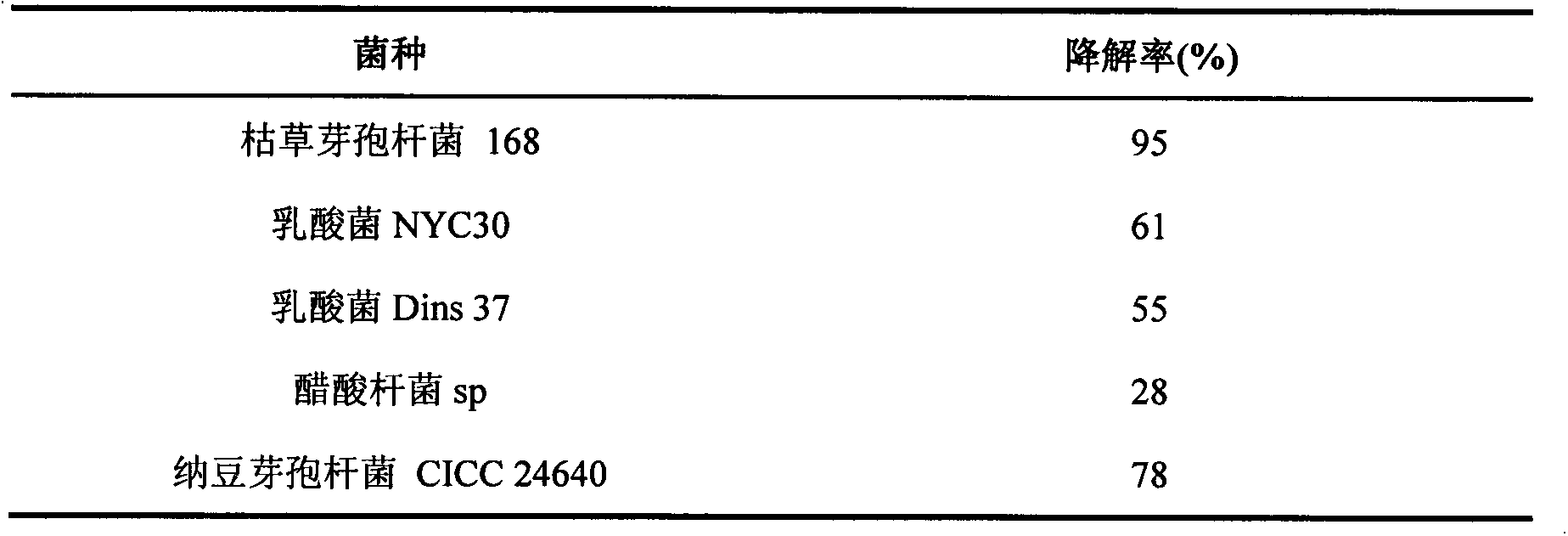

A zearalenone and microorganism technology, applied in the field of microorganisms, can solve the problems of low degradation rate, time-consuming and laborious organic solvents, high cost, and achieve the effects of high degradation efficiency, short degradation period and product safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

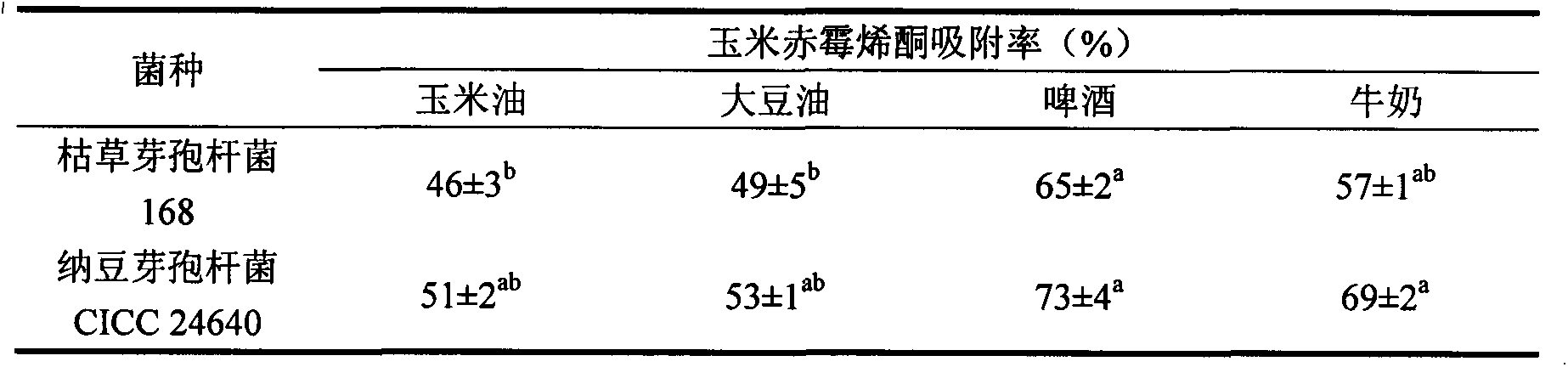

[0027] (1) Bacillus subtilis 168 and Bacillus natto CICC24640 were selected as the experimental strains, and appropriate medium and culture conditions were selected for inoculation and activation.

[0028] (2) Take 4 mL of corn oil, soybean oil, beer and milk, and add ZEN to make liquid food with a final concentration of ZEN of 0.5 μg / mL as the degradation matrix.

[0029] (3) Take Bacillus subtilis 168 and Bacillus natto CICC246403g respectively, and inactivate them by high-pressure steam (121°C, 20min). The inactivated Bacillus subtilis 168 and Bacillus natto CICC24640 were inoculated in the aforementioned strain degradation matrix. The samples were incubated under anaerobic conditions at 30°C for 1 h. The obtained suspension was centrifuged at 10000rpm, 4°C for 10min. The supernatant was collected and ZEN was extracted with a mixture of chloroform-methanol (9:1 v / v) for detection. The adsorption rates of ZEN in different liquid food matrices adsorbed by two kinds of inac...

Embodiment 2

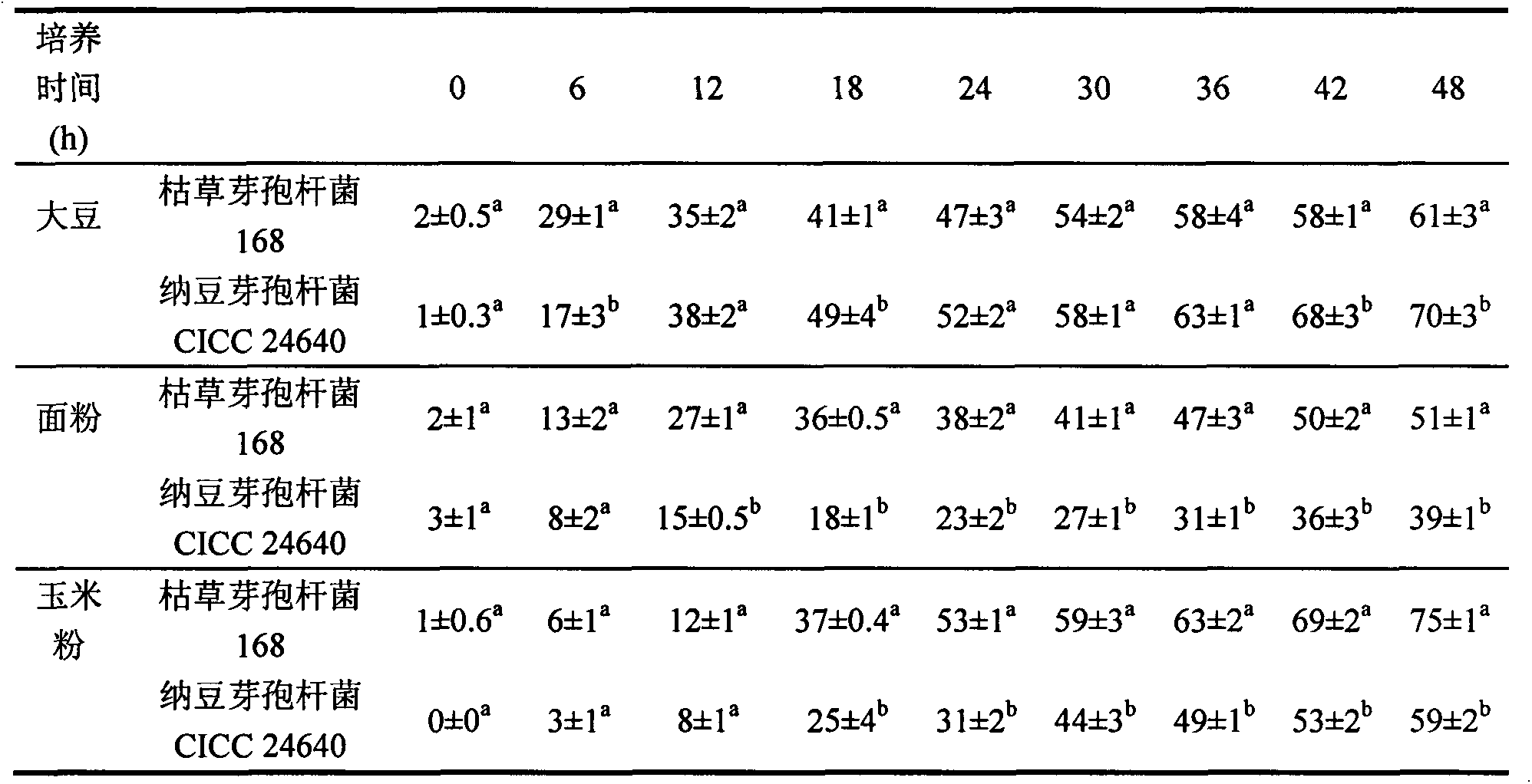

[0035] (1) Bacillus subtilis 168 and Bacillus natto CICC24640 were selected as the experimental strains, and appropriate medium and culture conditions were selected for inoculation and activation.

[0036] (2) Soybean, flour and corn flour were selected as solid substrates, and the moisture content and pH value of the samples were adjusted to 30% and 7, respectively. The solid substrate was stirred to form a paste, followed by autoclaving at 121° C. for 20 minutes.

[0037] (3) Add ZEN to the sample base to make the final concentration 1mg / kg, and then inoculate 1mL of the overnight cultured strain (10 8 cfu / mL), all samples were performed in duplicate. The samples were incubated in a 37°C incubator after mixing. After 0h, 6h, 12h, 18h, 24h, 30h, 36h, 42h, and 48h, take out a certain amount and add chloroform-methanol (9:1, v / v) mixture to extract zearalenone, and use UPLC-DAD The ZEN in the sample is determined. Table 3 shows the degradation rates of ZEN in different soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com