Biodegradable environment protection tableware and its processing method

An environmental protection and tableware technology, applied in the direction of dining table utensils, household utensils, applications, etc., can solve the problems of poor mechanical strength, fragile products, and not fully environmentally friendly, and achieve high mechanical strength and short degradation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The weight percentage of its components is: starch: 60%; low-density polyethylene: 2.5%; polyethylene: 20%; polyethylene wax: 3%; glyceryl monostearate: 2%; ethylene-vinyl acetate copolymer : 5%; titanium dioxide: 3%; light calcium carbonate: 2%; talcum powder: 2%; aluminum-titanium composite coupling agent: 0.35%; modifier: 0.01%; 0.04%.

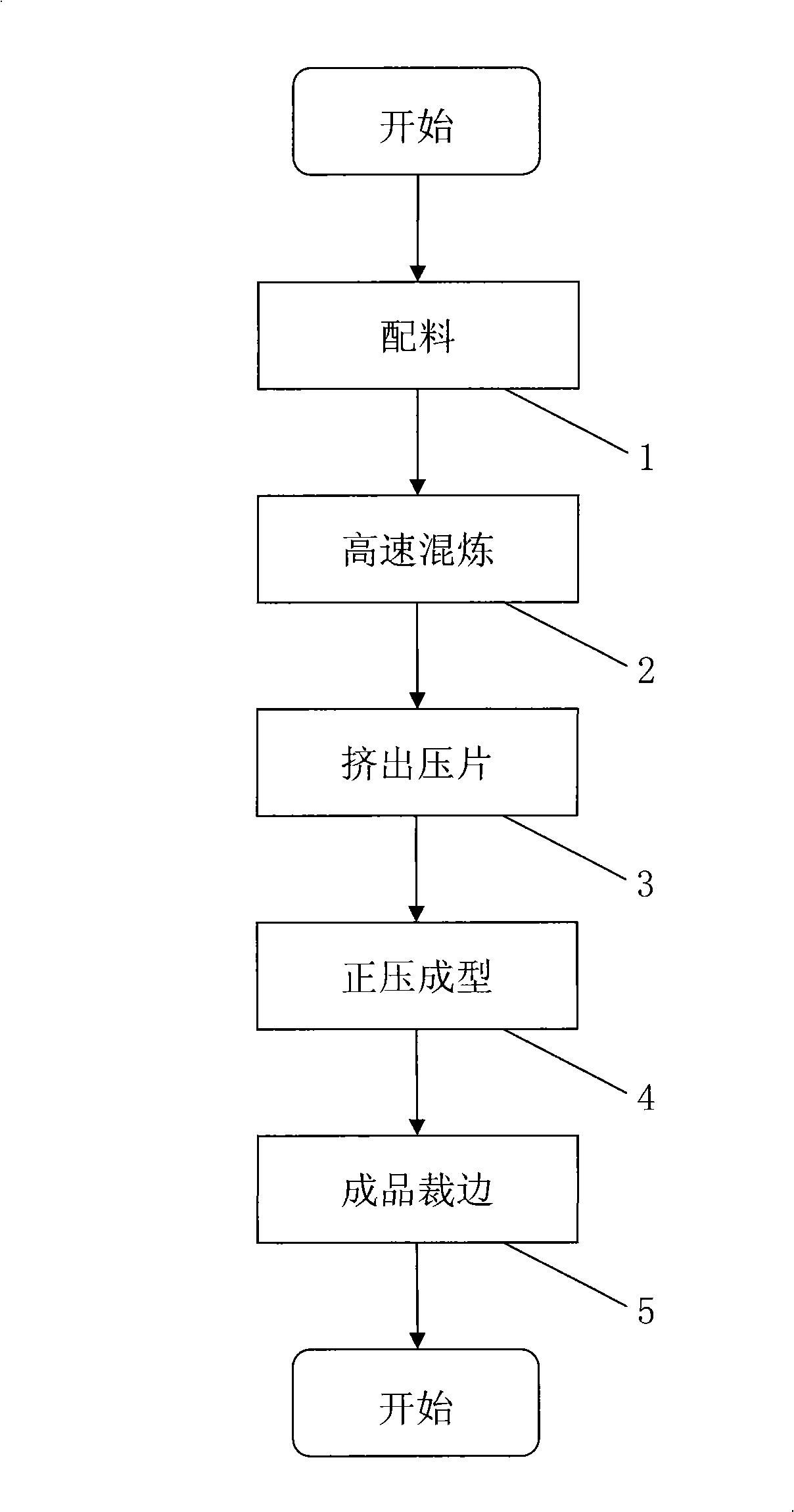

[0025] figure 1 It is a flow chart of the processing method of the biodegradable environment-friendly tableware in the present invention. Including the following steps:

[0026] Ingredient 1: Take the following materials and percentage by weight: starch: 30-60%; low-density polyethylene: 2.5-7%; polyethylene: 20-42%; polyethylene wax: 1-3%; monostearic acid Glyceride: 1-2%; Ethylene-vinyl acetate copolymer: 3-5%; Titanium dioxide: 1-3%; Light calcium carbonate: 2-6%; Talc powder: 1-3%; Aluminum-titanium composite Coupling agent: 0.2-0.5%; Improver: 0.01-0.02%; Antioxidant: 0.1-0.2%; Antioxidant: 0.04-0.06%.

[0027] High-speed m...

Embodiment 2

[0032] The difference between this embodiment and the first embodiment is that the weight percentage of each component is slightly changed, as follows: starch: 30%; low-density polyethylene: 7%; polyethylene: 42%; polyethylene wax: 3%; Glyceryl stearate: 2%; Ethylene-vinyl acetate copolymer: 5%; Titanium dioxide: 2%; Light calcium carbonate: 6%; Talc powder: 2.22%; Aluminum-titanium composite coupling agent: 0.5%; Improver: 0.02%; Antioxidant: 0.2%; Antioxidant: 0.06%.

Embodiment 3

[0034] The difference between this embodiment and the first embodiment is that the weight percentage of each component is slightly changed, specifically as follows: starch: 51%; low-density polyethylene: 4.5%; polyethylene: 35%; polyethylene wax: 1%; Glyceryl stearate: 1%; Ethylene-vinyl acetate copolymer: 3%; Titanium dioxide: 1%; Light calcium carbonate: 2.14%; Talc powder: 1%; Aluminum-titanium composite coupling agent: 0.2%; Improver: 0.01%; Antioxidant: 0.1%; Antioxidant: 0.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com