Production line of spunbond pulp-based nonwoven fabric and production technology thereof

A woven fabric and production line technology, applied in the production line and production process of non-woven fabrics, can solve the problems of not being able to avoid cellulose fiber pollution on the production line and production process, so as to avoid pollution and waste of resources, reduce production costs, loss avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

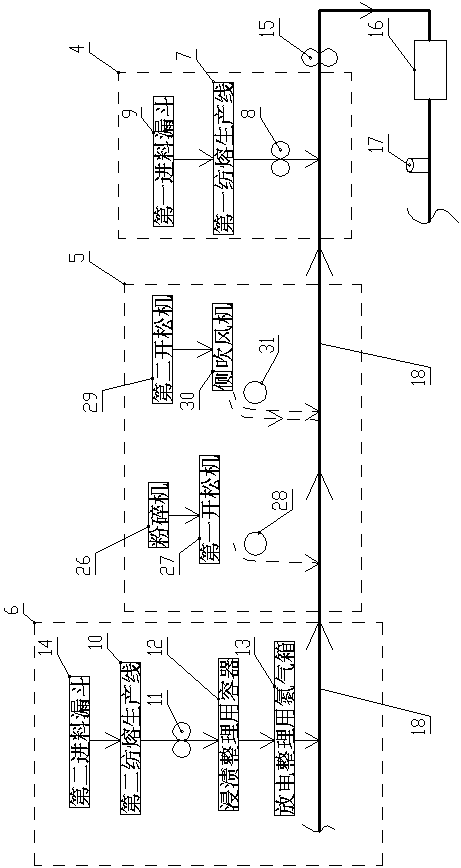

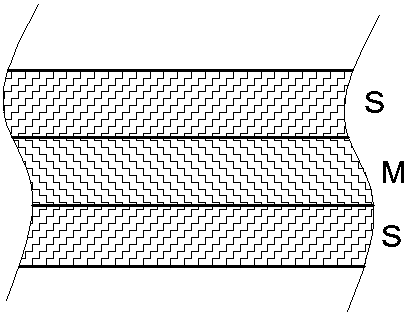

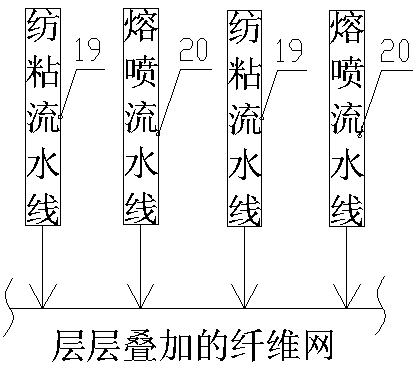

[0055] Such as Figure 1 to Figure 5 As shown, the present invention discloses a production line for the production of spunbonded pulp nonwoven fabrics, along the direction from raw material to finished product, which is upstream to downstream direction, including a layer of spunbonded nonwoven material for making a third layer The third layer line 6, the second layer line 5 for preparing the second layer of cellulose fiber layer and the first layer line 4 for preparing the first layer of spunbond nonwoven material layer;

[0056] Taking the direction from raw material to finished product as the direction from upstream to downstream, the third layer assembly line 6 is located at the most upstream of the production line of spunbonded pulp nonwoven fabric, and the first layer assembly line 4 is located in the downstream direction of the second layer assembly line 5;

[0057] The first layer of assembly line 4 includes a first spunmelt production line 7 and a first hot press 8 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com