Production method of amine borane complex

A production method and complex technology, applied in the field of amine borane complex production, can solve the problems of high production process cost, harsh experimental conditions, slow reaction, etc., and achieve moderate cost, equipment compatibility, and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, preparation of ethylenediamine borane complex

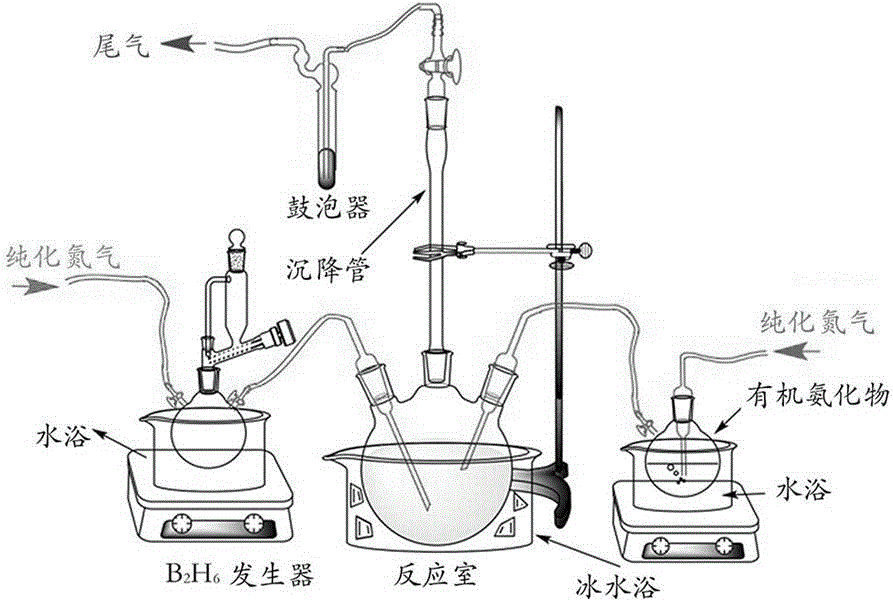

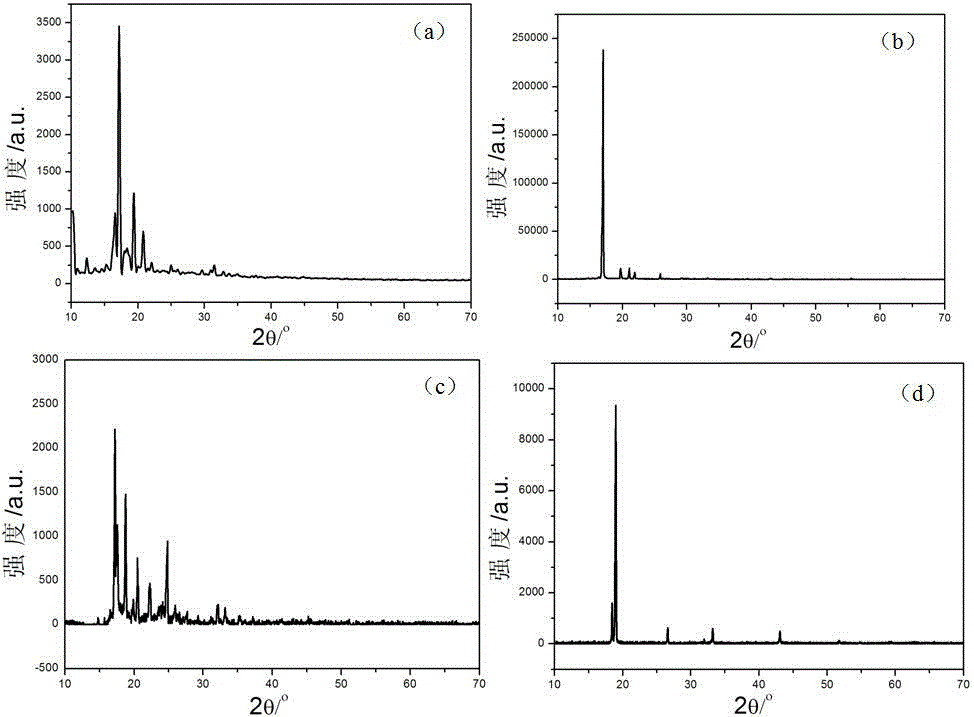

[0034] use figure 1 The reaction device, wherein the reaction chamber is a 1000mL glass three-necked bottle, operates at room temperature. 6.5g NaBH 4 Put it into the borane generator after grinding, put 5ml H2 SO 4 The solution was added to a constant pressure funnel, and the air in the reaction chamber was replaced with nitrogen, and 3 ml of anhydrous ethylenediamine was added to a flask placed in a hot water bath. During the reaction, the inert gas flow of ethylenediamine and the carrier gas of borane were connected, and the concentrated H 2 SO 4 Put the solution into the borane generator, react for 2 hours, close the settling tube and the ethylenediamine inert gas flow inlet valve after the white mist in the reaction chamber settles, and continue to add concentrated H 2 SO 4 After 0.5 hours of solution, the white pure EDAB product was collected. Product XRD results see figure 2 (a). This substan...

Embodiment 2

[0035] Embodiment 2, preparation of dimethylamine borane complex

[0036] use figure 1 A similar reaction device, wherein the reaction chamber is a 1000mL glass three-necked bottle, the three-necked bottle is placed in an ice-salt bath, and the borane uses industrial borane gas diluted with argon. The reaction chamber was first replaced with argon for air. During the reaction, the borane diluted with argon was first passed into the inert gas flow of dimethylamine, and after 1 hour of reaction, the borane gas was turned off, and the dimethylamine inert gas flow was continued to be passed into for 1 hour. After the ice-salt bath was removed, the reaction The chamber performs vacuum operation. The white dimethylamine borane complex product was collected after 3 hours in vacuo. Product XRD such as figure 2 (b) shown.

Embodiment 3

[0037] Embodiment 3, preparation of tert-butylamine borane complex

[0038] use figure 1 Reaction device, wherein the reaction chamber is a 1000mL glass three-necked bottle, and the borane generator is a 150mL glass three-necked bottle. 5 g LiBH 4 Put into the borane generator after grinding, put 4ml BCl 3 The solution was added to the constant pressure funnel. The reaction chamber was replaced with nitrogen for air. During the reaction, the inert gas flow of tert-butylamine and borane carrier gas were connected, and BCl was slowly added dropwise. 3 Put the solution into the borane generator, react for 2 hours, close the settling tube and the outlet valve of the borane generator after the white smoke in the reaction chamber settles, and collect the white pure tert-butylamine borane complex. Product XRD such as figure 2 (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com