Method for catalyzing and degrading phenolic wastewater through microwaves

A technology of microwave catalysis and phenol wastewater, applied in oxidation water/sewage treatment, illumination water/sewage treatment and other directions, can solve the problems of high cost of oxidant, complicated operating conditions, low treatment concentration, etc., and achieve complete degradation and simple operation. , the effect of low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

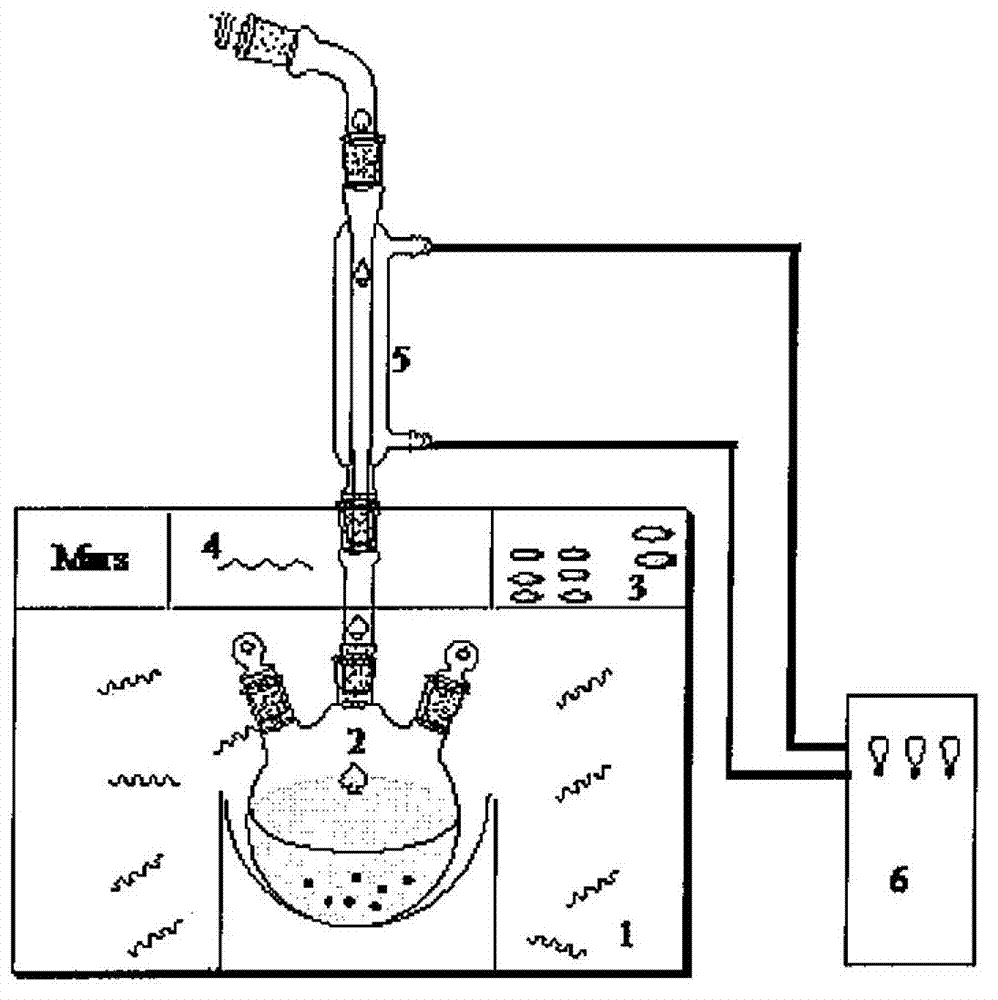

Method used

Image

Examples

Embodiment 1

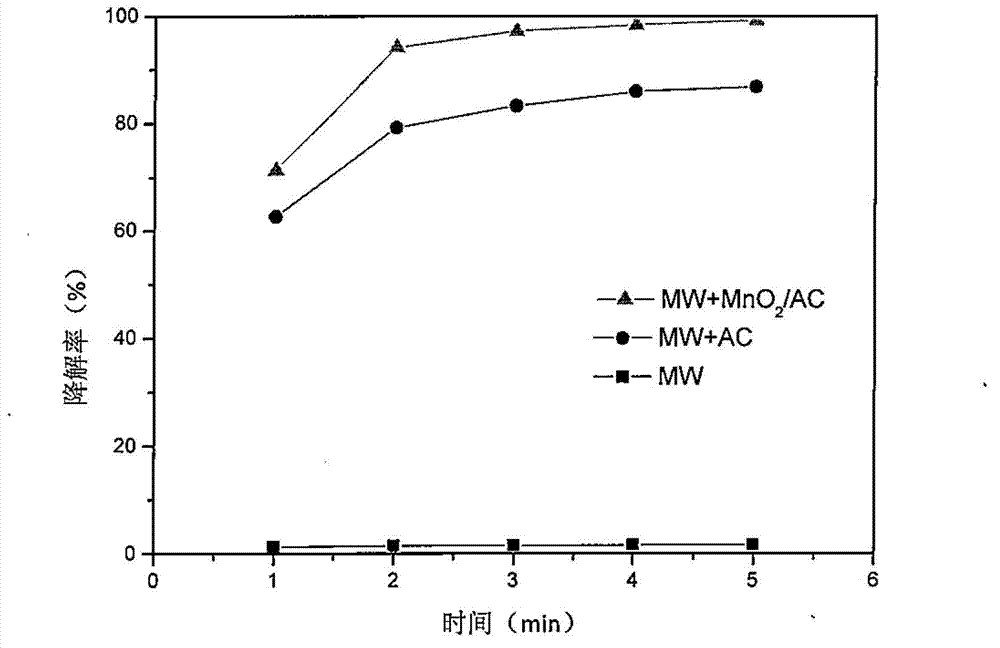

[0044] Take 100mL of 4-nitrophenol simulated wastewater with a concentration of 100mg / L, in only microwave radiation, microwave-activated carbon and microwave-MnO 2 Under the condition of / AC, the reaction was 1min, 2min, 3min, 4min and 5min respectively, the dosage of catalyst was 2g, and the microwave power was 400W. The above three kinds of reaction conditions affect the degradation rate of 4-nitrophenol as follows: figure 2 shown.

[0045] from figure 2 It can be seen that under the condition of only microwave radiation, the degradation rate is extremely low, and the existing partial degradation may be caused by thermal cracking of 4NP. After adding activated carbon into the microwave reaction system, the degradation rate reached 63.01% at 1 min, and reached 87.13% at 5 min with the extension of the reaction time. Because activated carbon is a very strong absorbing substance, when microwave is irradiated, activated carbon absorbs microwave energy, causing many active ...

Embodiment 2

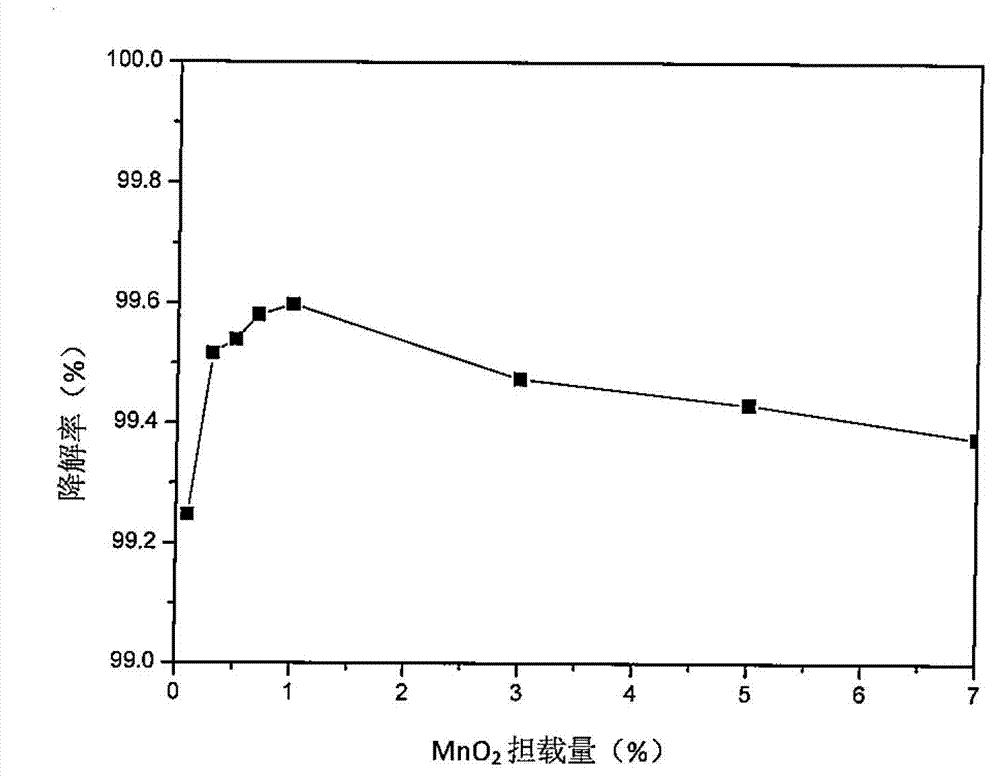

[0047] Take 100mL of 100mg / L 4-nitrophenol simulated wastewater, under the conditions of catalyst dosage 3g, microwave power 400W, and reaction time 5min, investigate MnO 2 The loads are respectively 0.1%, 0.3%, 0.5%, 0.7%, 1.0%, 3.0%, 5.0% and 7.0% on the degradation rate, the results are as follows image 3 shown.

[0048] AC load MnO 2 The post-degradation rate reached more than 99%, compared with that without loading MnO 2 Compared with the activated carbon catalytic degradation of 4-nitrophenol, the degradation rate is significantly improved. Because the load MnO 2 After that, the surface active components of the catalyst increased, and when the loading amount was 1%, the degradation rate was the highest, reaching 99.59%. However, when the loading amount is greater than 1%, since the adsorption of manganese nitrate on the surface of activated carbon reaches saturation during the impregnation process, the MnO 2 The dispersibility on the surface of activated carbon is ...

Embodiment 3

[0050] When the power is 400W, 100ml of 100mg / L 4-nitrophenol is experimentally analyzed. When the reaction time is 3min, 4min and 5min, the catalyst dosage is respectively 0.5g, 1g, 1.5g and 2g to degrade 4-nitrophenol. the influence of Figure 4 shown.

[0051] With the prolongation of catalyst dosage and reaction time, the degradation rate increased continuously, especially at 0.5-1g, the degradation rate increased the most. As the amount of catalyst increases, there are more "hot spots" on the surface of the catalyst and the rapid degradation of 4-nitrophenol. When the amount of catalyst is greater than 1g, most of the organic matter has been degraded, so the degradation rate basically tends to be stable. When the amount of catalyst is 2g and the reaction time is 5min, the degradation rate reaches 99.45%. If the amount of catalyst continues to increase, the degradation rate does not increase significantly, because the catalytic oxidation reaction is a reversible reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com