Edible camellia oil cold pressing process

A process and oil cooling technology, applied in the project field, can solve the problem of finished tea oil losing flavor, etc., achieve the effect of outstanding inherent flavor, good quality crude oil, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

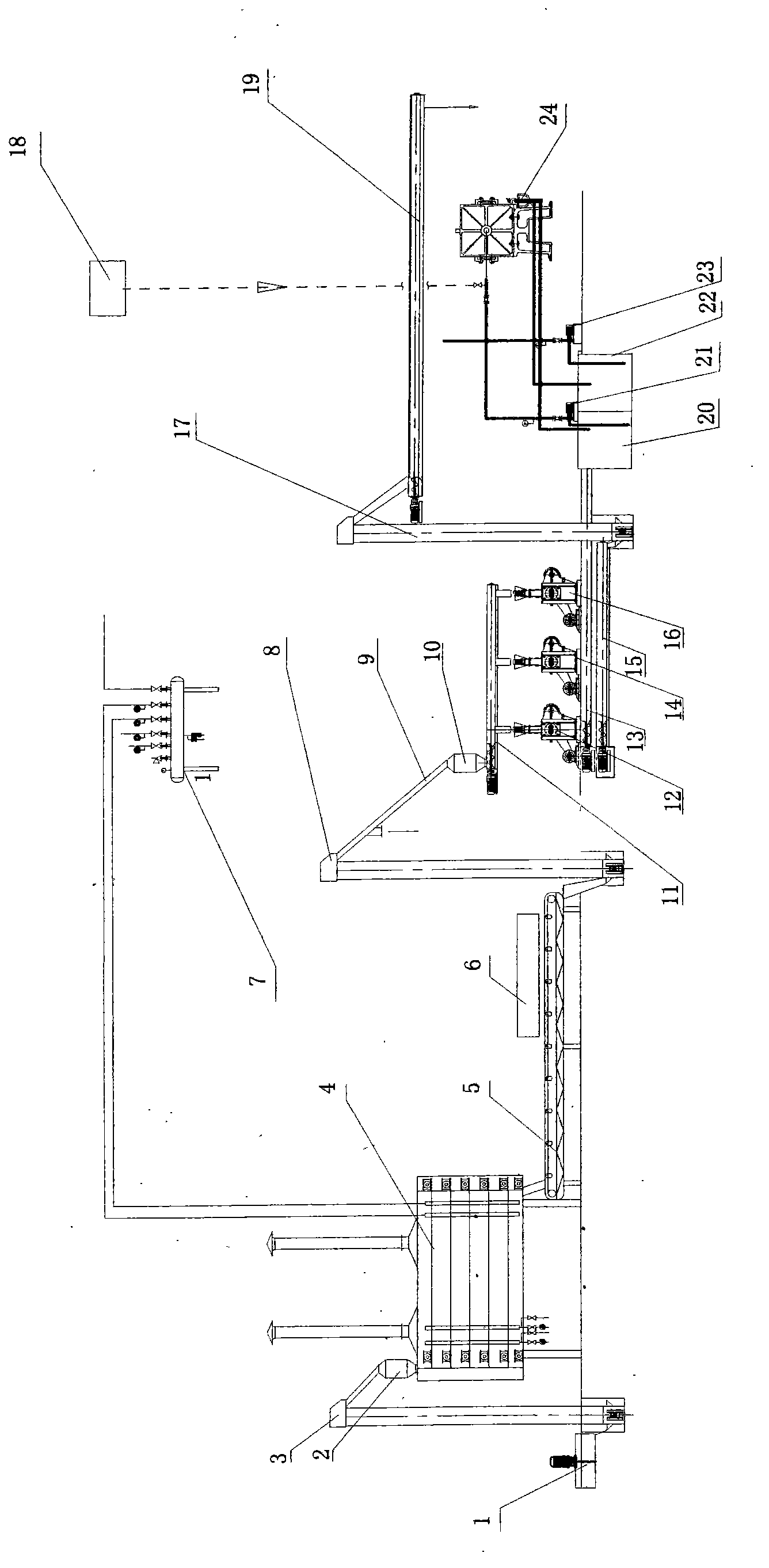

[0009] Process specific process of the present invention: the camellia oil seed enters the feeder 1 and is transported to the No. 1 hoist 3 with a constant flow rate; the No. 1 hoist 3 is transported to the No. 1 magnetic separator 2 arranged on the flat-plate dryer 4 . No. 1 magnetic separator 2 absorbs iron-containing substances in oilseeds. The oilseed enters the flat dryer 4, which is equipped with a heating system; the steam delivered from the boiler is distributed to the flat dryer 4 through the steam distributor 7; the oilseed enters from the top of the flat dryer 4 , run from top to bottom layer by layer; the excess water in the oilseed is heated and evaporated, and the water vapor is transported out of the room through the steam extraction pipe arranged in the flat dryer 4. The oilseeds are dried to the appropriate moisture and transported to the flat conveyor 5, and the flat conveyor 5 is equipped with a microwave conditioning machine 6; when the oilseeds pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com