Asymmetric birefringence vortex fiber and manufacturing method of asymmetric birefringence vortex fiber

A birefringence and asymmetric technology, applied in cladding optical fiber, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult preparation of optical fiber, and achieve the effect of good spatial flexibility and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

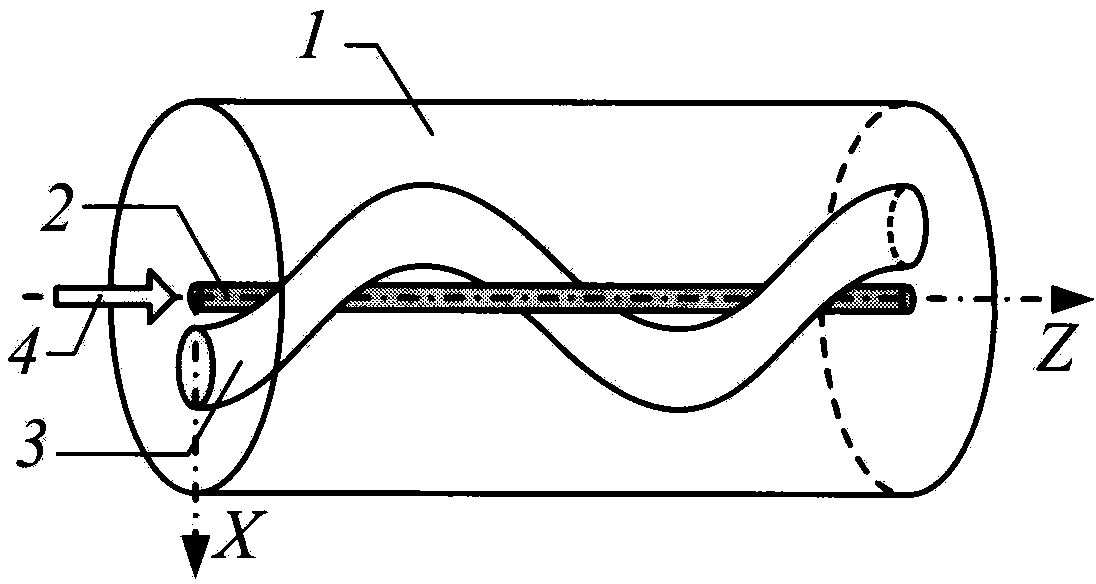

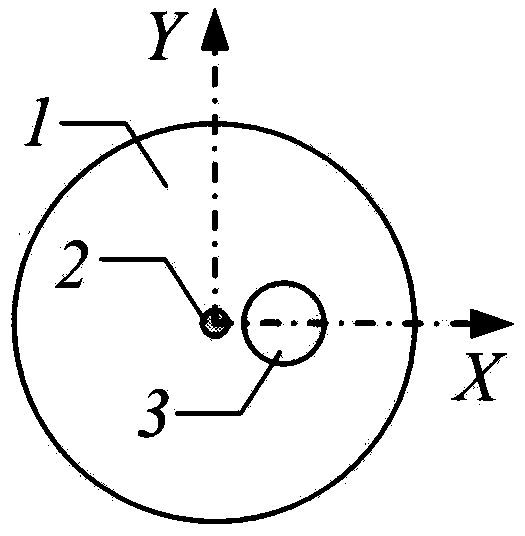

[0031] Secondly, the preparation method of the asymmetric birefringent vortex fiber is given. The preparation process of this asymmetric birefringent vortex fiber with a single helical stress region can be divided into the following steps (such as Figure 6 and Figure 7 ):

[0032] Step 1: If Figure 6 , punching an eccentric hole 7 in the optical fiber preform 6 containing the core 5, and then inserting the stress region preform 8 into the eccentric hole 7, thus obtaining an optical fiber preform 9 with a single stress region;

[0033] Step 2: If Figure 7 , the optical fiber preform 9 is placed on the drawing tower, under the joint action of the vertical traction force 10 and the torsional force 11, it is twisted and drawn, and after heating and corresponding post-treatment 12, it is prepared into an asymmetric birefringent vortex with a single helical stress region Spin the fiber 13.

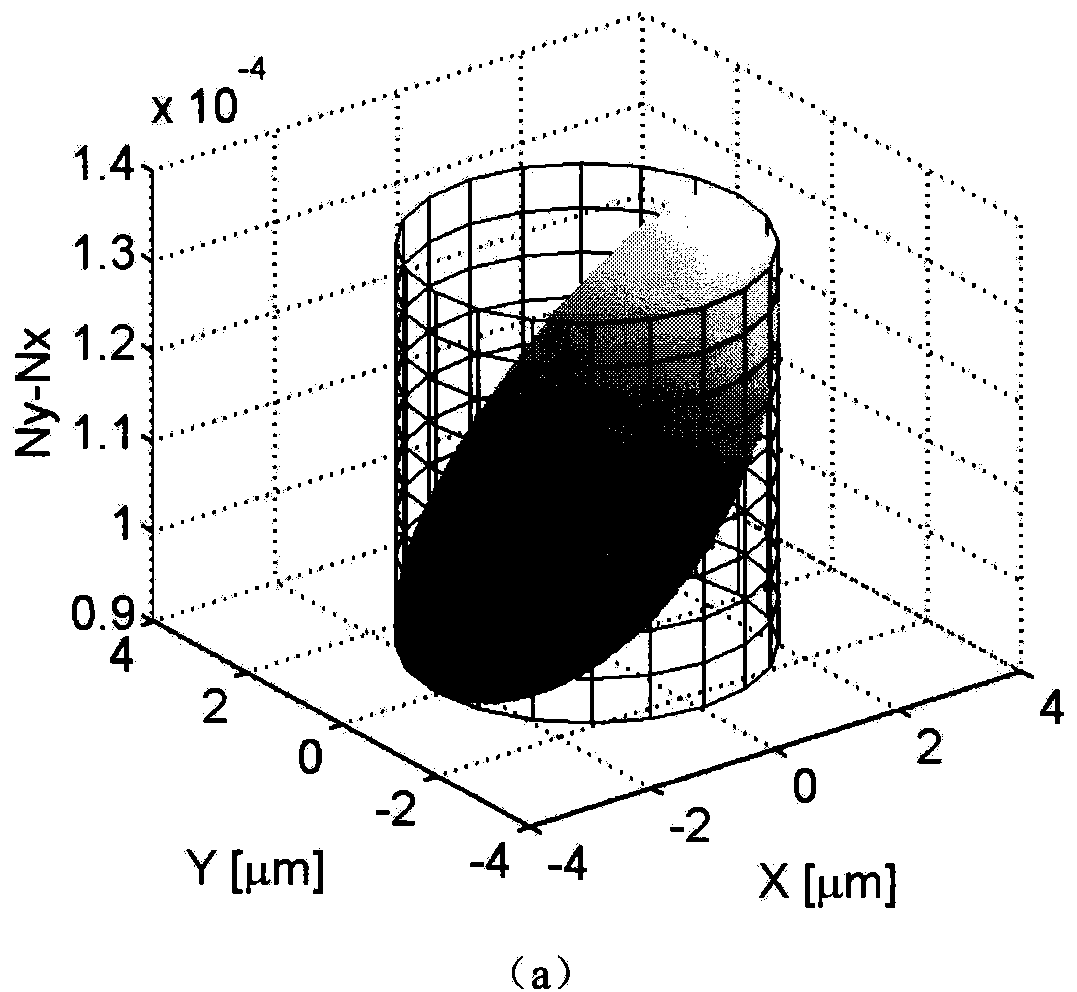

[0034] combine Figure 8 and Figure 9 Different from the first embodiment, the a...

Embodiment 1

[0039] 1. Optical fiber preparation: according to the optical fiber preparation method of the first embodiment, an asymmetric birefringent vortex optical fiber 13 with a single helical stress region is prepared;

[0040] 2. Light source coupling: cutting the prepared asymmetric birefringent vortex fiber 13 with a single helical stress region, and then aligning and welding it with the single-mode fiber 20 with a light source pigtail, such as Figure 13 shown;

[0041] 3. Generation of vortex beams: After inputting the laser light 21, the transmission of vortex light mode can be realized in the asymmetric birefringent vortex fiber 13 with single helical stress region, and the quasi-vortex beam can be output at the fiber end.

Embodiment 2

[0043] 1. Optical fiber preparation: according to the optical fiber preparation method of the second embodiment, an asymmetric birefringent vortex optical fiber 19 with a double helical stress region is prepared;

[0044] 2. Light source coupling: cutting the prepared asymmetric birefringent vortex fiber 19 with a double-helix stress zone, and then aligning and welding it with the single-mode fiber 20 with a light source pigtail, such as Figure 14 shown;

[0045] 3. Generation of vortex beams: After inputting laser light 21, vortex light mode transmission can be realized in the asymmetric birefringent vortex fiber 19 with double helical stress region, and vortex-like beams can be output at the fiber end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com