Tail gas aftertreatment device, selective catalytic reduction (SCR) front exhaust gas temperature control system and control method thereof

A technology of exhaust temperature and control system, which is applied in the direction of electronic control of exhaust gas treatment device, diagnosis device of exhaust gas treatment device, exhaust gas treatment, etc., can solve the problems of high cost, complicated structure of exhaust gas after-treatment device , to achieve the effect of low cost, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

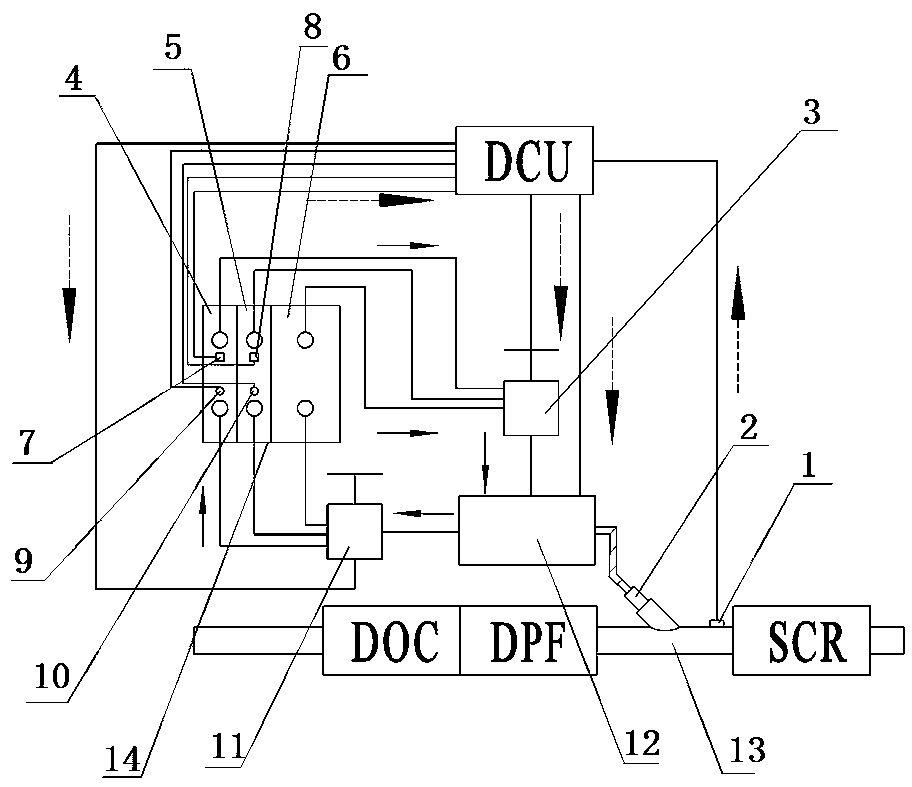

[0055] like figure 1 As shown, the exhaust temperature control system before the SCR includes a controller and a cooling channel 13 for connecting the DPF and the SCR. The controller includes a urea metering control unit (DCU); the cooling channel 13 is provided with installation holes for assembling urea injection Device 2. When the urea injector 2 is installed, its injection port extends into the inside of the cooling channel 13, and the joint between the urea injector 2 and the cooling channel 13 is provided with a gasket to seal the joint to prevent exhaust gas from leaking out. The end of the cooling channel 13 is used to connect the SCR, and the exhaust temperature sensor 1 is installed on the part between the connection of the urea injector 2 and the end of the cooling channel 13, and the urea metering control unit (DCU) can accept the exhaust temperature sensor 1 detected temperature signal.

[0056] The exhaust temperature control system before the SCR also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com