Surface treatment device for vehicle carrying board producing and manufacturing

A surface treatment device and a car carrier technology, which are applied in the direction of manufacturing tools, grinding machines, and parts of grinding machine tools, can solve the problems of poor grinding quality, low efficiency, and inconvenience in fixing the car carrier, so as to improve the grinding efficiency and quality. , easy to fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

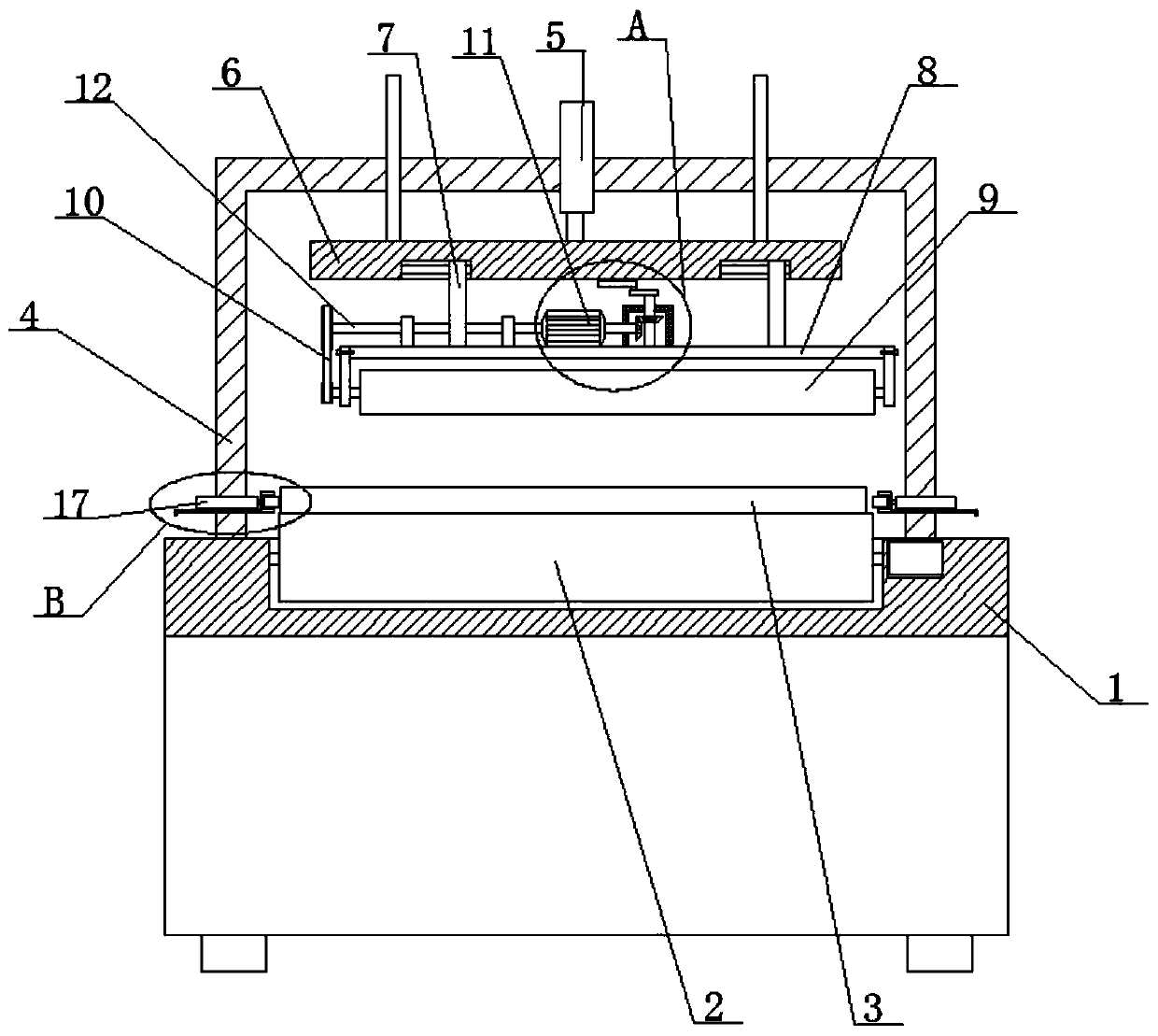

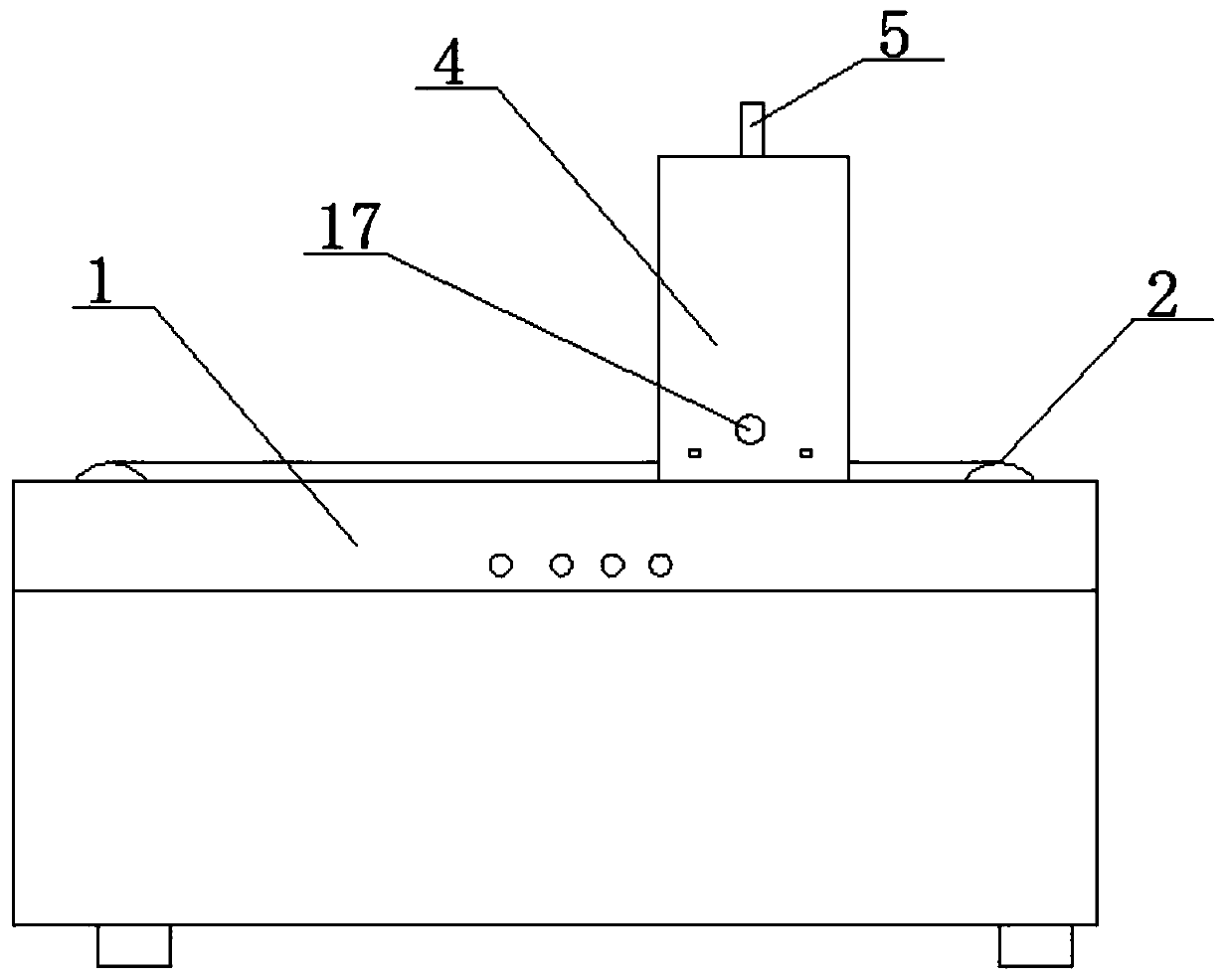

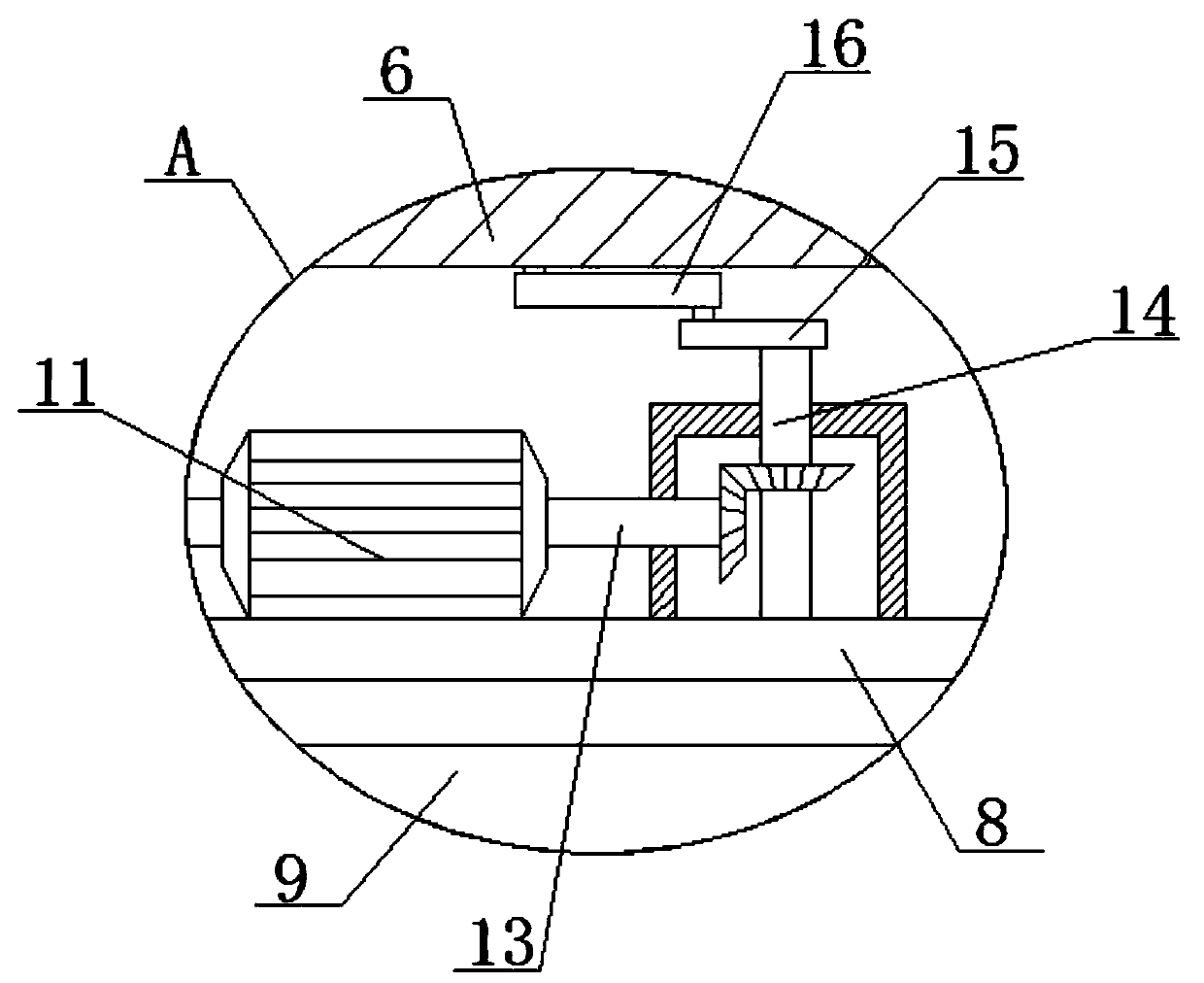

[0024] refer to Figure 1-5 , a surface treatment device for the production and manufacture of vehicle-carrying boards, including a frame 1, a conveyor belt device 2 is arranged on the frame 1, a plate 3 is conveyed on the conveyor belt device 2, a metal shell 4 is arranged on the top of the frame 1, and the metal shell 4 There is a push rod cylinder 5 on the top, the output of the push rod cylinder 5 is fixedly connected with a lifting plate 6, and the bottom of the lifting plate 6 is slidingly connected with two connecting rods 7, and the bottom ends of the two connecting rods 7 are fixedly installed with the same Housing 8, the top of the housing 8 is provided with a double-head motor 11, the bottom of the housing 8 is rotatably installed with a roller 9, the outer fixed sleeve of the roller 9 is provided with a grinding sleeve, and the two output shafts of the double-head motor 11 are respectively fixedly connected Left side shaft 12 and right side shaft 13 are arranged, a...

Embodiment 2

[0030] refer to Figure 1-5 , a surface treatment device for the production and manufacture of vehicle-carrying boards, including a frame 1, a conveyor belt device 2 is arranged on the frame 1, a plate 3 is conveyed on the conveyor belt device 2, a metal shell 4 is arranged on the top of the frame 1, and the metal shell 4 A push rod cylinder 5 is arranged on the top, and the output of the push rod cylinder 5 is fixedly connected with a lifting plate 6 through a screw thread. The bottom of the lifting plate 6 is slidingly connected with two connecting rods 7, and the bottom ends of the two connecting rods 7 are fixed by welding. The same shell 8 is installed, the top of the shell 8 is provided with a double-head motor 11, the bottom of the shell 8 is rotatably equipped with a roller 9, the outer fixed sleeve of the roller 9 is provided with a grinding sleeve, and the two output shafts of the double-head motor 11 The left shaft 12 and the right shaft 13 are respectively fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com