Intelligent debugging method and system based on handshake protocol

A technology of intelligent adjustment and handshake protocol, applied in control/adjustment system, general control system, computer control, etc., can solve problems such as material waste, achieve less handshake times, less macro variables, and save adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

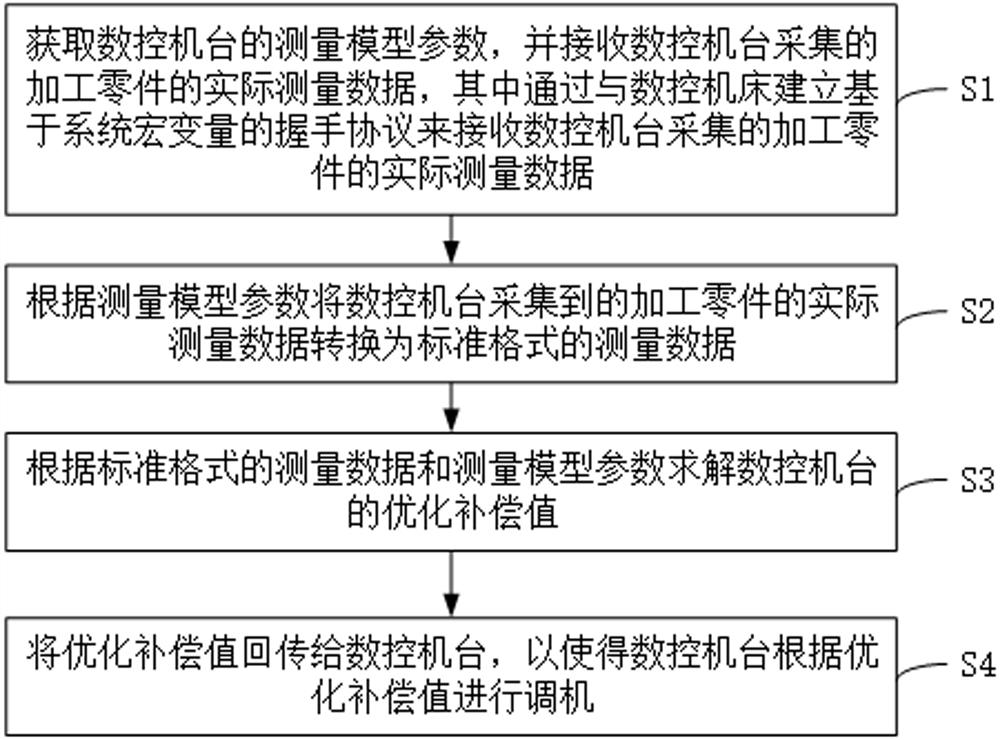

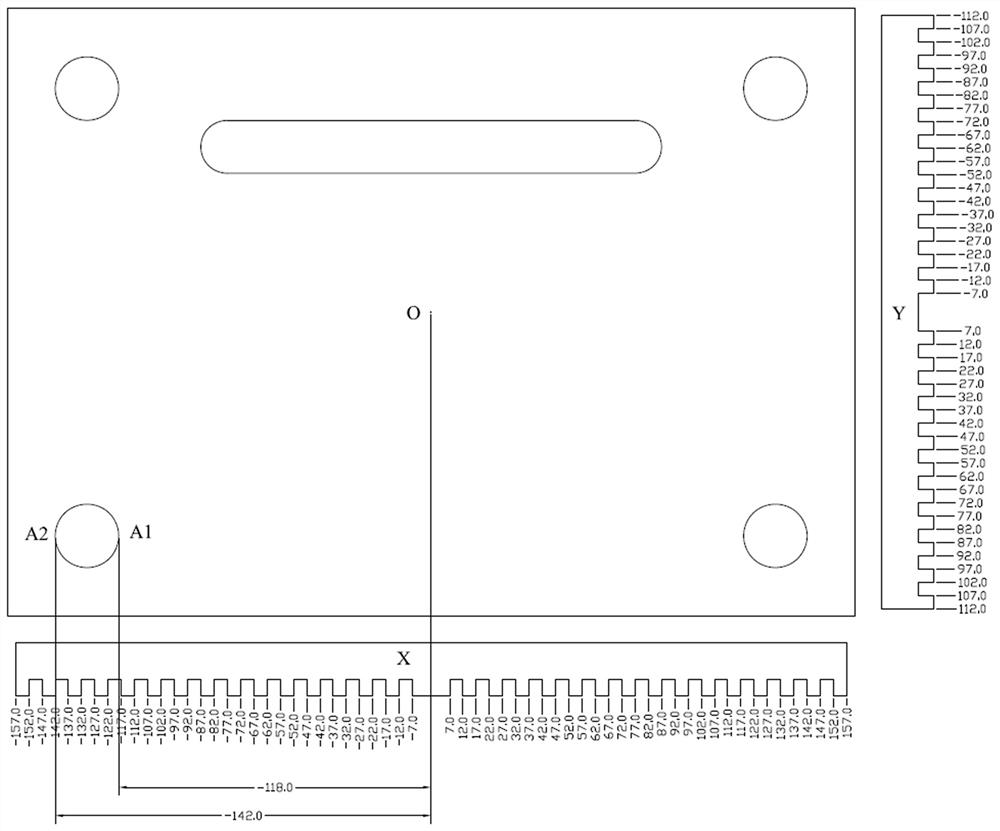

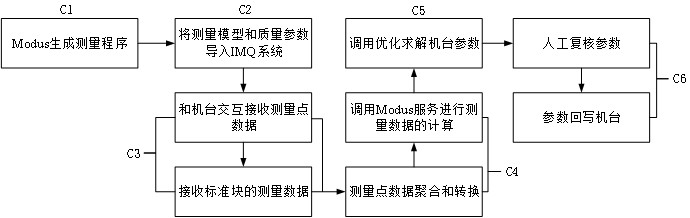

[0050] The preferred embodiment of the present invention discloses an intelligent adjustment method based on the handshake protocol, which is used for intelligent adjustment of at least one numerical control machine, so that the adjustment process is smoother, and the adjustment compensation data reaches the target at one time. The target process is: after the machining of the CNC machine is completed, the probe is used to measure the size points in the machine. The system collects the measurement points in real time to calculate each size value of the part. The system page visually displays the size measurement results of the processed parts and automatically calculates all The optimal value of the tool compensation and coordinate system compensation involved in the processing, the compensation value can be written back to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com