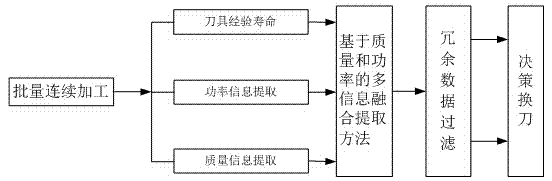

Multimodal fusion based gear machining process tool change decision method

A technology of processing process and decision-making method, which is applied in the fields of information processing, network and communication technology, and machinery manufacturing industry. It can solve the problems of inaccurate tool change guidance, high requirements for sensor stability and reliability, etc., and meet the processing quality requirements. , low cost, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Processing workpiece: gear;

[0026] Machine tool: YS3118CNC5 five-axis CNC high-speed gear hobbing machine;

[0027] Sensor: WBQ212P71;

[0028] Terminal: iTouch121A(-T) embedded information terminal;

[0029] A / D converter: HTK-NDC1 Ethernet field measurement and control server.

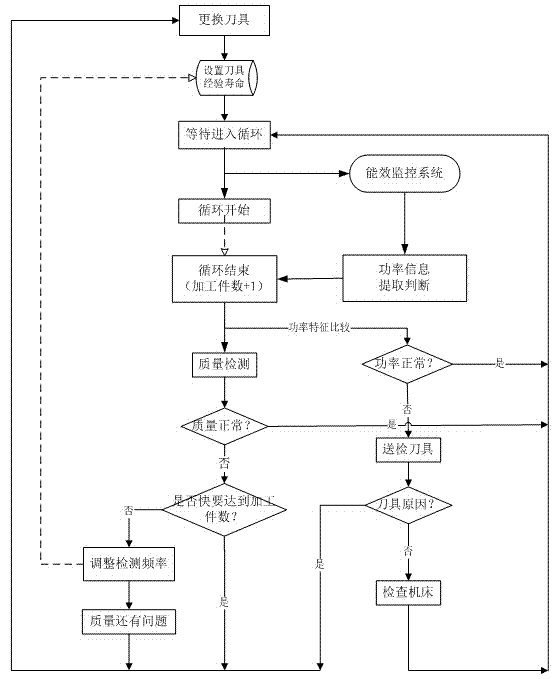

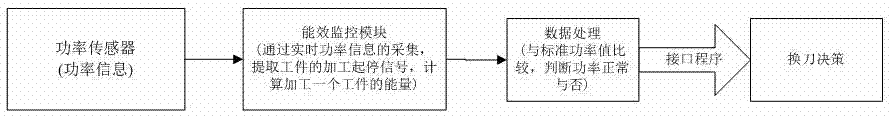

[0030] The decision-making process of tool change in the batch processing of gears is as follows: figure 2 As shown, after replacing a new tool, the empirical life of the tool is set according to experience. After adjusting the machine tool to process a qualified product, set the power information consumed by processing this workpiece as a standard value, and store it in the computer or embedded terminal as the basis for subsequent power information identification. Every time a workpiece is processed, the power information of this processing is processed and compared with the standard power data to obtain the power status of this processing. If necessary, conduct random inspection on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com