A kind of soybean product sewage treatment method and system

A sewage treatment method and sewage pretreatment technology, which are applied in the fields of water/sewage multi-stage treatment, neutralized water/sewage treatment, food industry wastewater treatment, etc. Uneven water quality and other problems, to achieve the effect of large amount of water treatment, stable treatment and efficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

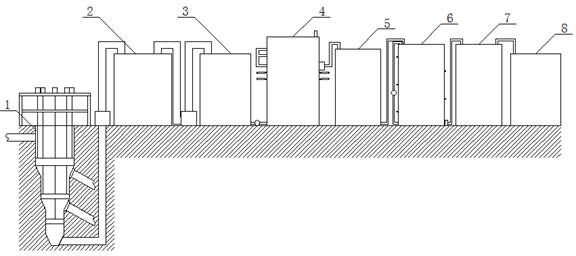

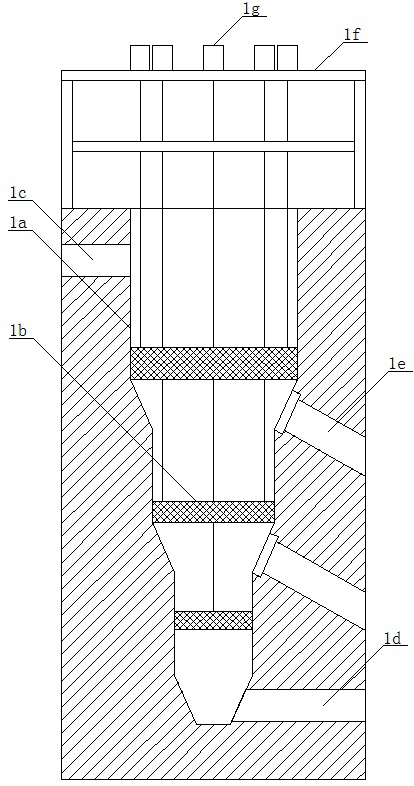

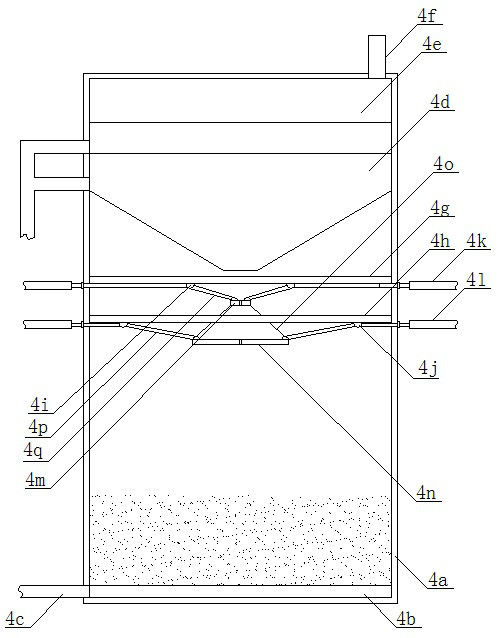

[0078] The method for treating soybean product sewage comprises the following steps: filtering the soybean product sewage with a filter grid, and transporting the suspended solids and floating objects; taking the filtered sewage and adding sodium hydroxide for primary precipitation; taking the upper liquid and adding pH Regulator, adjust the pH value to 6; then send the liquid into the anaerobic reaction tank for reaction, and recover the generated biogas; after the reacted liquid is filtered to remove scum, it is sent to the biological contact oxidation reaction tank for reaction; The reacted liquid is added with coagulant and flocculant for flocculation and precipitation, and after standing for stratification, the supernatant is discharged.

Embodiment 2

[0080] The method for treating soybean product sewage comprises the following steps: filtering the soybean product sewage with a filter grid, and transporting the suspended solids and floating objects; taking the filtered sewage and adding sodium hydroxide for primary precipitation; taking the upper liquid and adding pH Regulator, adjust the pH value to 8; then send the liquid into the anaerobic reaction tank for reaction, and recover the generated biogas; after the reacted liquid is filtered to remove scum, it is sent to the biological contact oxidation reaction tank for reaction; The reacted liquid is added with coagulant and flocculant for flocculation and precipitation, and after standing for stratification, the supernatant is discharged.

Embodiment 3

[0082] The method for treating soybean product sewage comprises the following steps: filtering the soybean product sewage with a filter grid, and transporting the suspended solids and floating objects; taking the filtered sewage and adding sodium hydroxide for primary precipitation; taking the upper liquid and adding pH Regulator, adjust the pH value to 7; then send the liquid into the anaerobic reaction tank for reaction, and recover the generated biogas; after the reacted liquid is filtered to remove scum, it is sent to the biological contact oxidation reaction tank for reaction; The reacted liquid is added with coagulant and flocculant for flocculation and precipitation, and after standing for stratification, the supernatant is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com