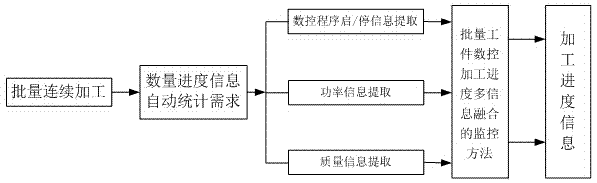

Multi-information fusion based automatic collection method for batched numerical control workpiece machining progress

A technology of multi-information fusion and automatic collection, which is applied in the fields of information processing, network and communication technology, and machinery manufacturing, can solve the problems of redundant statistics of processing quantities and inaccurate acquisition of production progress information, etc., achieve timely data feedback and improve optimization Run, statistic rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Processing workpiece: gear;

[0028] Machine tool: YS3118CNC5 five-axis CNC high-speed gear hobbing machine;

[0029] Sensor: WBQ212P71;

[0030] Terminal: iTouch121A(-T) embedded information terminal;

[0031] Analog / digital converter: HTK-NDC1 Ethernet field measurement and control server;

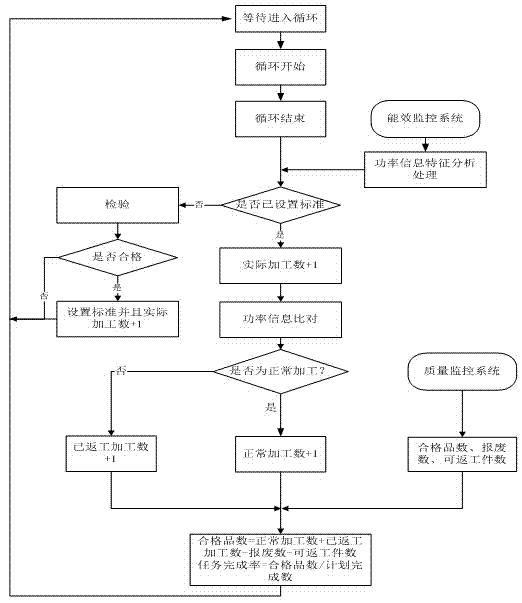

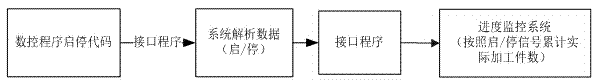

[0032] For the automatic collection process of gear hobbing batch processing progress, please refer to figure 2 As shown, the processing starts after the extra bed is running, and the processing start and stop information in the NC program is obtained through the interface program during the processing; the actual number of pieces processed increases by 1 when the cycle is started and stopped, and the power information of this processing is analyzed and processed, and Compare with the standard power information (if the standard has not been set, the workpiece will be inspected, and if it is qualified, the power information of the processed workpiece will be set as the standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com