Concrete anti-crack self-repairing agent, preparation method thereof and anti-crack self-repairing concrete

A self-repairing and concrete technology, which is applied in the field of concrete, can solve problems such as application limitations of repairing methods, and achieve the effects of strong practicability, simple preparation and operation, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

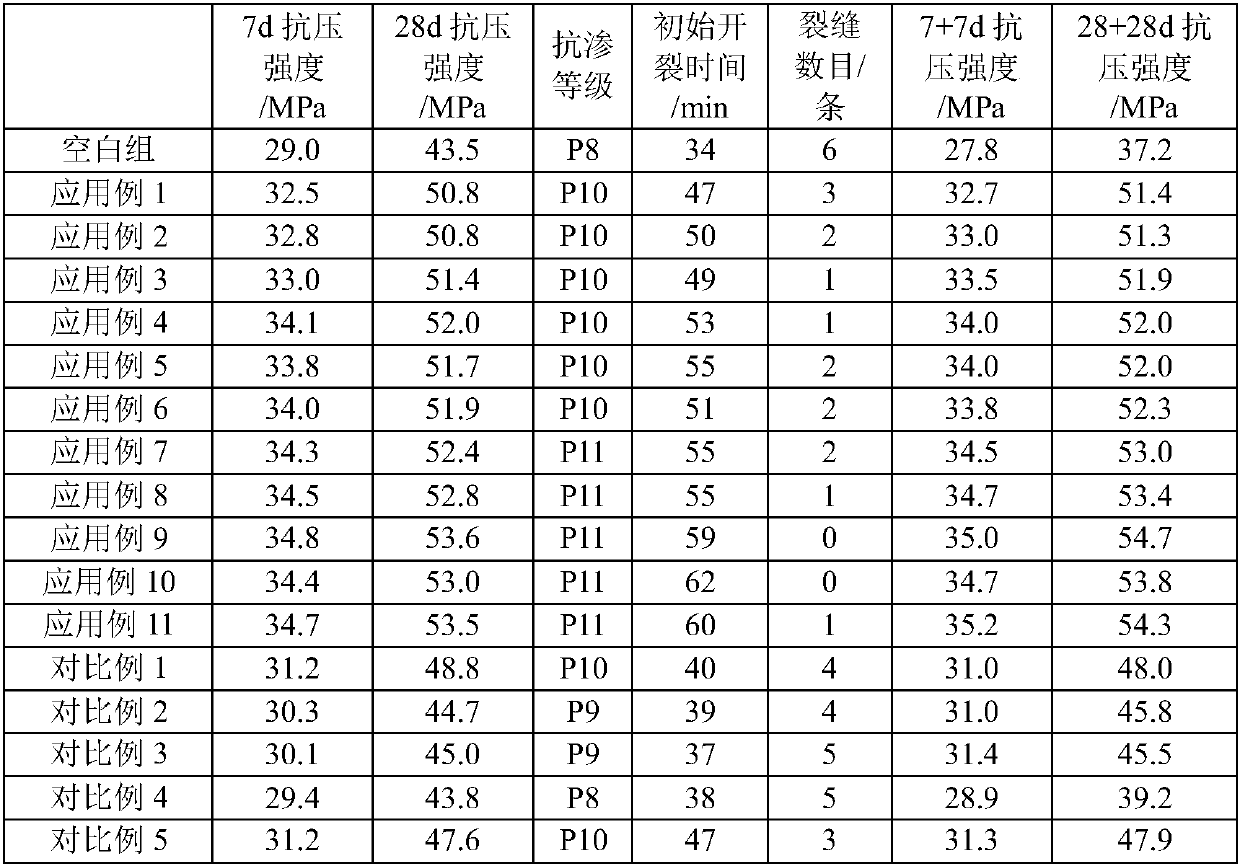

Examples

Embodiment 1

[0032]A concrete anti-cracking self-healing agent, which is prepared by the following method: 35kg of calcium sulfoaluminate, 0.1kg of magnesium aluminum silicate thixotropic agent, 0.3kg of polyvinyl alcohol fiber, 1kg of nano-scale carbon black, 2kg of glucose and phenolic acid Add 3kg of protein into the blender, mix and stir evenly.

Embodiment 2

[0034] A concrete anti-crack self-healing agent, which is prepared by the following method: calcium sulfoaluminate 10kg, calcium oxide 35kg, magnesium aluminum silicate thixotropic agent 0.3kg, polyvinyl alcohol fiber 0.1kg, nano-scale carbon black 1.5kg Add 3kg of glucose and 4kg of casein into a blender, mix and stir evenly.

Embodiment 3

[0036] A concrete anti-cracking self-healing agent, which is prepared by the following method: 20kg of silica fume, 32kg of calcium oxide, 0.5kg of magnesium aluminum silicate thixotropic agent, 1kg of polyvinyl alcohol fiber, 1.8kg of nano-scale carbon black, glucose Add 3.4kg and 5kg of casein into the blender, mix and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com