Beef cattle slaughtering method

A technology of beef cattle and bovine body, applied in the field of animal husbandry, can solve the problems of shortened shelf life of cold fresh beef, prolong fresh preservation time, rapid increase of safety risks, healthy development, etc. The effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

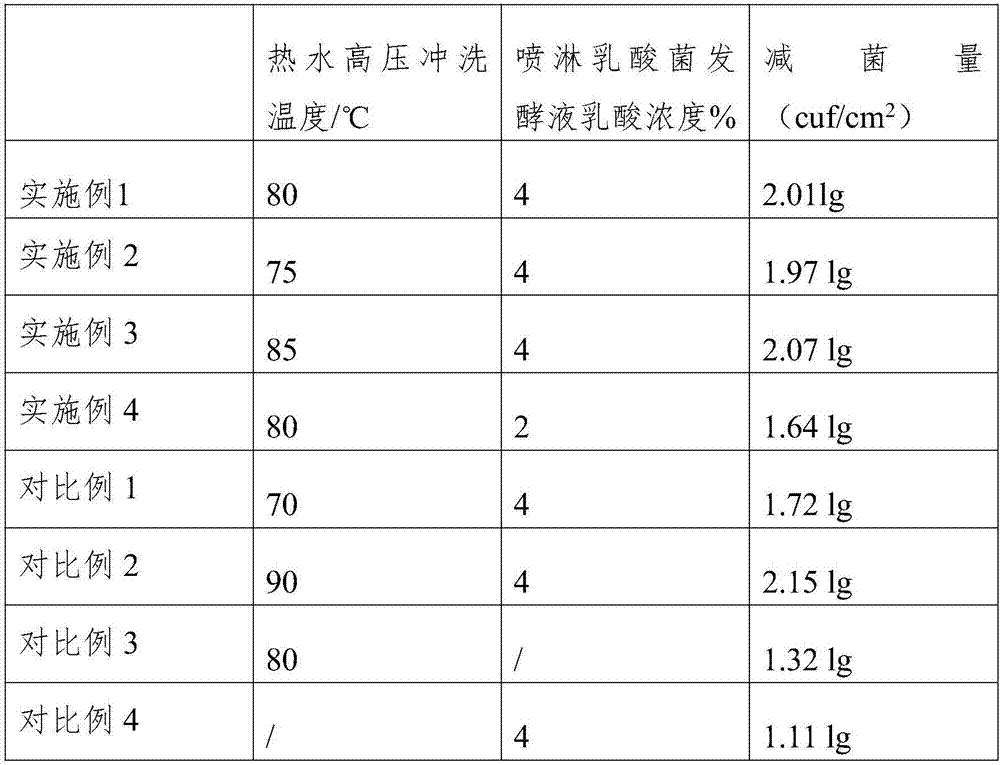

Examples

Embodiment 1

[0028] A method for slaughtering beef cattle, comprising the steps of:

[0029] (1) Pre-slaughter treatment: stop the cattle to be slaughtered for 24 hours, take a bath, weigh them, and drive them into the slaughter workshop;

[0030] (2) Assassination and bloodletting: assassination and bloodletting are carried out in the live slaughter method, the bleeding time is 10 minutes, electrical stimulation is performed, the electrical stimulation voltage is controlled at 8V, the current frequency is 50HZ, and the stimulation time is 30s. beef hind legs;

[0031] (3) Turning and pre-stripping: transfer and hang the cow body after cutting the hind legs, and stretch the cow's hind legs to pre-stretch the cow body;

[0032] (4) Peeling processing: the pre-peeled cow body is peeled by the machine, and the peeled cowhide is sent to the cowhide workshop;

[0033] (5) Carcass processing: cut off the head of the cow, tie the esophagus to prevent the stomach from flowing out, saw the chest ...

Embodiment 2

[0041] A method for slaughtering beef cattle, comprising the steps of:

[0042] (1) Pre-slaughter treatment: stop the cattle to be slaughtered for 24 hours, take a bath, weigh them, and drive them into the slaughter workshop;

[0043] (2) Assassination and bloodletting: assassination and bloodletting are carried out in the live slaughter method, the bleeding time is 10 minutes, electrical stimulation is performed, the electrical stimulation voltage is controlled at 8V, the current frequency is 50HZ, and the stimulation time is 30s. beef hind legs;

[0044] (3) Turning and pre-stripping: transfer and hang the cow body after cutting the hind legs, and stretch the cow's hind legs to pre-stretch the cow body;

[0045] (4) Peeling processing: the pre-peeled cow body is peeled by the machine, and the peeled cowhide is sent to the cowhide workshop;

[0046] (5) Carcass processing: cut off the head of the cow, tie the esophagus to prevent the stomach contents from flowing out, saw o...

Embodiment 3

[0054] A method for slaughtering beef cattle, comprising the steps of:

[0055] (1) Pre-slaughter treatment: stop the cattle to be slaughtered for 24 hours, take a bath, weigh them, and drive them into the slaughter workshop;

[0056] (2) Assassination and bloodletting: assassination and bloodletting are carried out in the live slaughter method, the bleeding time is 10 minutes, electrical stimulation is performed, the electrical stimulation voltage is controlled at 8V, the current frequency is 50HZ, and the stimulation time is 30s. beef hind legs;

[0057] (3) Turning and pre-stripping: transfer and hang the cow body after cutting the hind legs, and stretch the cow's hind legs to pre-stretch the cow body;

[0058] (4) Peeling processing: the pre-peeled cow body is peeled by the machine, and the peeled cowhide is sent to the cowhide workshop;

[0059] (5) Carcass processing: cut off the head of the cow, tie the esophagus to prevent the stomach contents from flowing out, saw o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com