Patents

Literature

72results about "Food ingredient as raising agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite food raising agent and applications thereof

InactiveCN103564273AQuality improvementImprove qualityFood ingredient as raising agentFood shapingSodium bicarbonateFood additive

The invention discloses a composite food raising agent. The raising agent comprises, by weight, a first component and a second component accounting for 40% of the first component, wherein the first component comprises 10% of sodium bicarbonate, 15% of calcium hydrogen phosphate, 35% of potassium bitartrate, 25% of sodium lactate, and 15% of citric acid, and the second component selects corn starch. The composite food raising agent can be used as a food additive replacing alum and used in food processing, especially in starch product (such as dry vermicelli, vermicelli and sheet jelly) processing. The composite food raising agent improves the quality and the grade of the products, thus achieving an objective of replacing the alum innocuously and harmlessly and improving the comprehensive quality and grade of the products. In addition, the invention also discloses applications of the composite food raising agent.

Owner:QINGJIAN COUNTY JIUTIAN POTATO IND

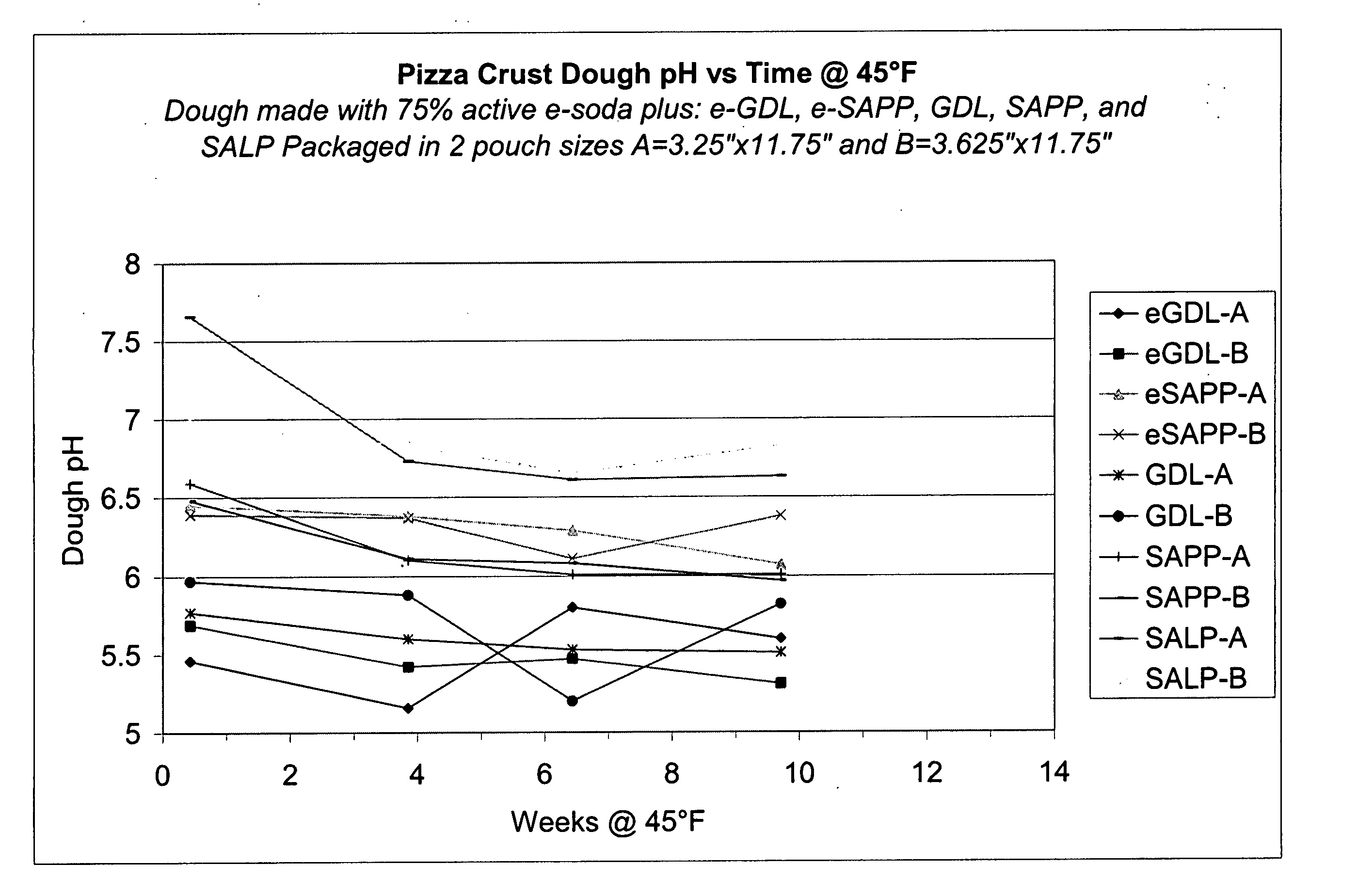

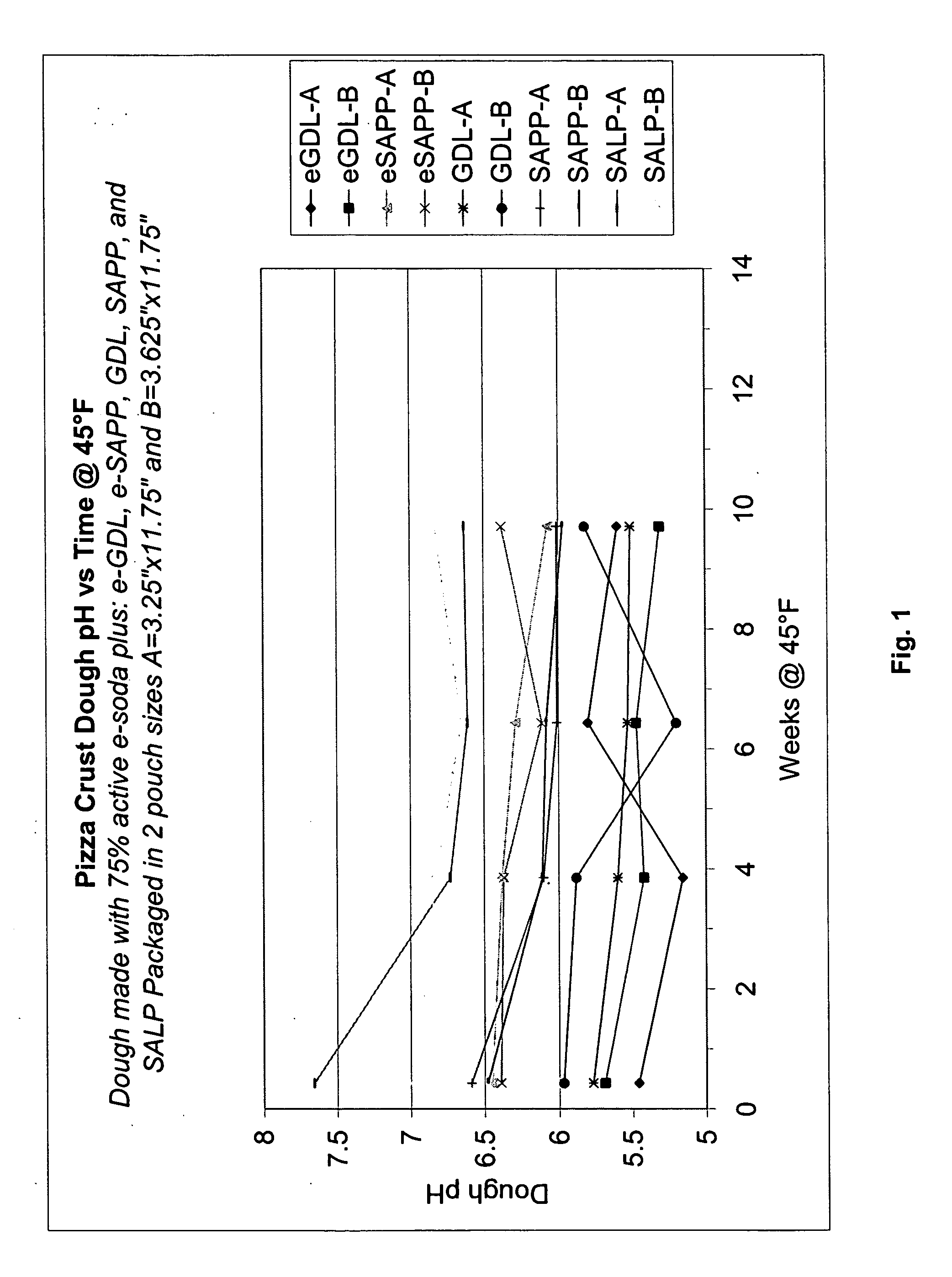

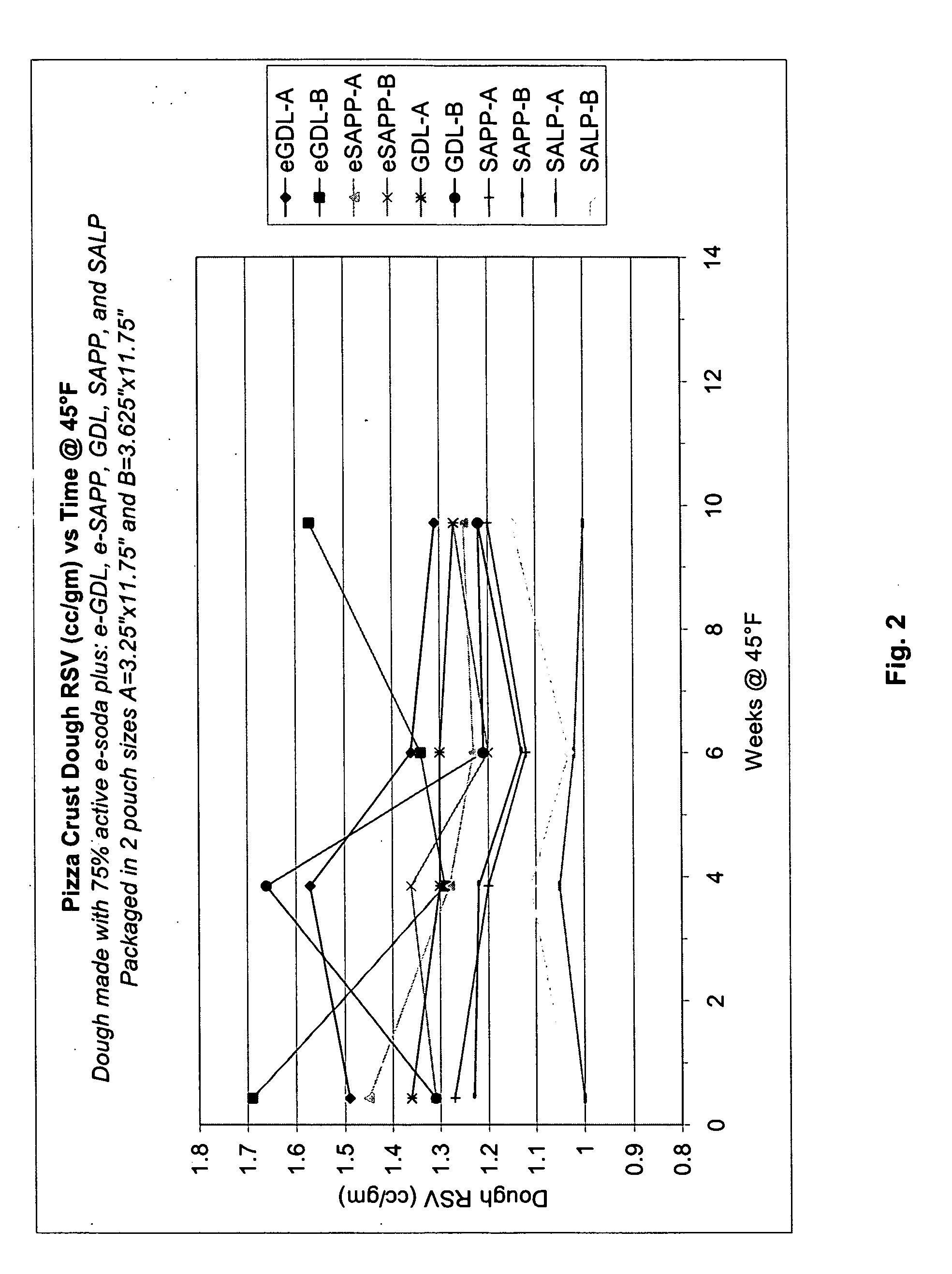

Packaged, developed dough production in low pressure package, and related methods

ActiveUS20050281922A1Sufficient volumeIncrease volumeReady-for-oven doughsConfectioneryCompound (substance)Refrigerated temperature

Owner:GENERAL MILLS INC

Alkaline leavening agent microcapsule and preparation method thereof

ActiveCN105310055AImprove stabilityStrong controllabilityFood ingredient as raising agentGaseous food ingredientsOrganic solventDecomposition

The invention discloses an alkaline leavening agent microcapsule. The alkaline leavening agent microcapsule is prepared through adopting glycerin monostearate as the wall material and adopting an alkaline leavening agent as the core material, has good stability, gas generation controllability and granulation performance, is not influenced by the external environment at a low temperature, and is stable in physicochemical performance; when the temperature reaches 65 DEG C, the wall material melts, the core material, namely, the alkaline leavening agent, is released, and at the moment, the core material can release CO2 more effectively through thermal decomposition or neutralization or double decomposition reaction with acid matters, so that the purpose of better leavening is achieved. With supercritical CO2 fluid adopted as a solvent, a preparation method provided by the invention has the characteristic that the preparation technology is simple, the traditional drying process is not required, the preparation condition is easy to control, an organic solvent is not used in the preparation process, and the obtained product is safe and nontoxic.

Owner:YANGTZE UNIVERSITY

Caramel-flavor melon seeds and preparation method thereof

InactiveCN106333325AIncrease appetiteEnhanced caramel flavorSugar food ingredientsFood ingredient as raising agentTriticum turgidumSugar

The invention relates to the technical field of food processing, in particular to caramel-flavor melon seeds and a preparation method thereof. The caramel-flavor melon seeds are prepared from 380-420 parts of shelled melon seeds, 250.3-270.3 parts of high gluten wheat flour, 115.1-145.1 parts of low gluten wheat flour, 80-94 parts of corn starch, 27.2-35.2 parts of glutinous rice flour, 18.8-22.8 parts of edible salt, 4.0-5.6 parts of raising agent, 108-120 parts of white granulated sugar, 108-120 parts of water, 4.5-4.9 parts of caramel syrup and 0.6-0.8 part of caramel essence. Crispy shells are formed on the surfaces of the melon seeds, the taste is crispy and delicious, the melon seeds are brown, smooth in appearance and rich in caramel fragrance after being fried, the appetite of people can be promoted, and energy lacked in the body can be supplemented in time. The preparation method is easy to operate and control and suitable for industrial application and popularization.

Owner:ZHENGZHOU RONGLIDA BIOLOGICAL TECH CO LTD

Filling improver, soup-stock filling, double-layer soup-protecting steamed stuffed bun, and preparation method thereof

ActiveCN106962763AImprove freeze-thaw stabilityRich in physiological nutritionFood ingredient as thickening agentYeast food ingredientsFiberFreeze thawing

The invention relates to the technical field of cooked wheaten food processing, in particular to a filling improver, soup-stock filling, a double-layer soup-protecting steamed stuffed bun, and a preparation method thereof. The filling improver is prepared by compounding wheat fiber, orange fiber, oat fiber and edible gelatin; and the filling improver is added in the filling. The double-layer soup-protecting steamed stuffed bun by wrapping the filling with two layers of wrappers comprising inner-layer unleavened dough wrapper or spring roll wrapper and outer-layer leavened dough wrapper. Three kinds of dietary fiber and the edible gelatin are compounded and used, high water-retaining property, oil-retaining property, thermal reversibility and freeze-thaw stability are given to the filling, the soup content is not reduced when the soup is reheated after long-time quick-frozen preservation of the filling, the soup is locked and is prevented from being permeated into the wrapper, and the taste of the whole product is improved. The double-layer steamed stuffed bun provided by the invention protects the soup of the filling from permeating outwards, solves the problems that the filling of the quick-frozen steamed stuffed bun is dry and does not have soup and the wrapper absorbs the soup of the steamed stuffed bun and is sticky, and achieves the taste and the state of the fresh steamed stuffed bun.

Owner:SYNEAR FOOD CO LTD

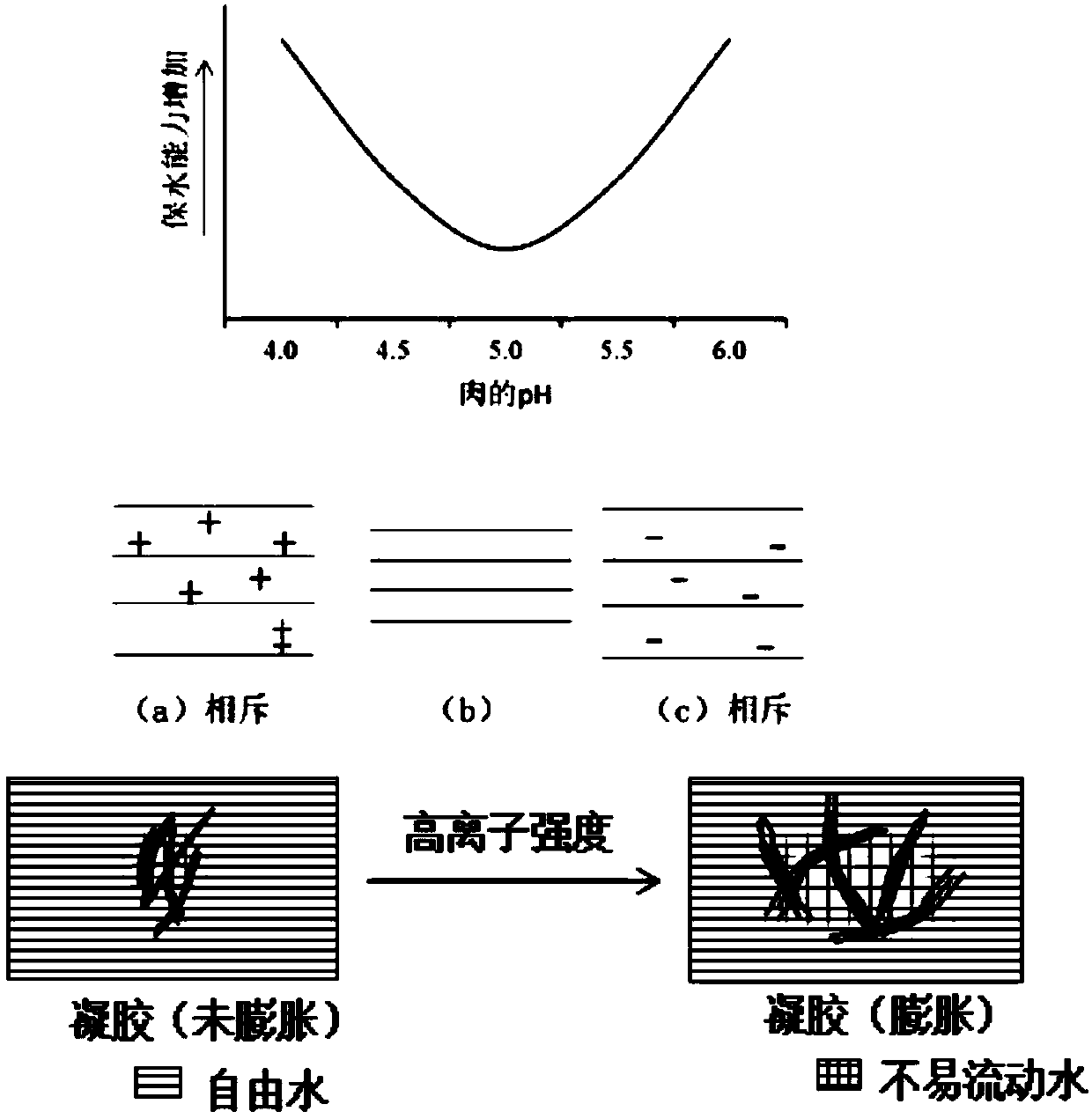

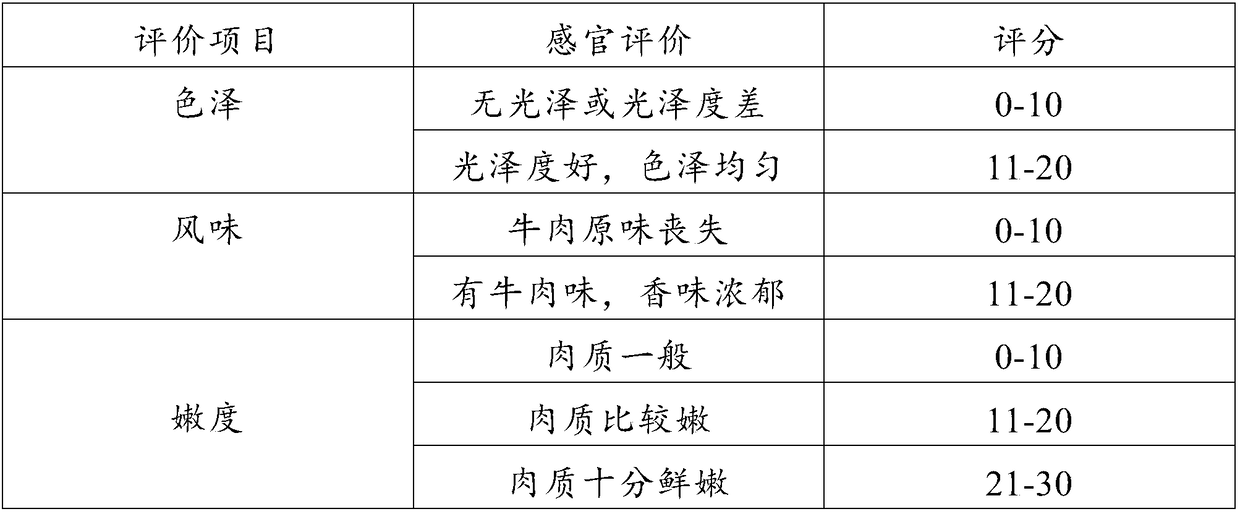

Compound water retaining agent capable of improving bullfrog quality and application method of compound water retaining agent

InactiveCN109588645AImprove water retentionImprove qualityFood ingredient as antioxidantFood ingredient as raising agentSodium bicarbonateSolubility

The invention provides a compound water retaining agent capable of improving bullfrog quality and an application method of the compound water retaining agent. Raw materials of the compound water retaining agent comprise polyphosphate and sodium bicarbonate, polyphosphate is basic, can increase pH of bullfrog and can also binds with polyvalent metal ions binding with structural protein of muscle, so that carboxyl groups get free from protein, the protein is enabled to be negatively charged, and electrostatic repulsion between the carboxyl groups is increased. Polyphosphate can provide higher ionic strength, can improve solubility of myofibrillar proteins and the like, is beneficial to transformation of muscle protein into a loose state and can also dissociate actomyosin, water retention ofmeat is improved, and tenderness of the meat is improved. Sodium bicarbonate can also provide a basic environment and improve meat bulkiness, so that the protein structure of the treated bullfrog getslooser, the water retention is improved substantially, the tenderness is improved, eating quality of the bullfrog is improved, and the market of the bullfrog is further expanded.

Owner:新派(上海)餐饮管理有限公司

Fermented bean coated food and production method thereof

InactiveCN106900964ASolve indigestibleClear grainConfectioneryFood ingredient as raising agentAdditive ingredientPre treatment

The invention relates to fermented bean coated food. The food is prepared from components in parts by weight as follows: 100 parts of pretreated fermented beans, 50-100 parts of coating powder, 50-100 parts of syrup and 5-10 parts of a flavoring. The fermented bean coated food solves the problem that common bean coated food cannot be digested easily, and meanwhile, the fermented bean coated food has more substances which are produced through fermentation metabolism and are beneficial to the human body than common beans.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Formula and preparation process of tartary buckwheat caramel treats suitable for diabetics

InactiveCN107927289AImprove nutritional balanceHigh nutritional valueConfectioneryFood ingredient as raising agentAlcohol sugarsSugar free

The invention relates to a formula and preparation process of tartary buckwheat caramel treats suitable for diabetics. The formula of the tartary buckwheat caramel treats suitable for the diabetics comprises the following components in parts by weight: 50 parts of fried fruit strips and 50 parts of sugar alcohol. The preparation process of the tartary buckwheat caramel treats suitable for the diabetics comprises the following steps: step 1, blending materials for the fried fruit strips according to fried fruit strip components and proportioning of the components, and conducting dough kneading;and step 2, wrapping dough with plastic cloth, and putting the wrapped dough at a temperature of 30-32 DEG C and at a humidity of 55-59 RH%, and conducting dough curing for 3.5 hours. The formula ofthe tartary buckwheat caramel treats suitable for the diabetics disclosed by the invention has higher and more uniform nutritional value and higher protein content, reduces risk of blood sugar risingafter eating, and is beneficial to the effective control of blood sugar of the diabetics. The preparation process of the tartary buckwheat caramel treats suitable for the diabetics processes the blended raw materials, and employs proper process conditions, so that the high-quality sugar-free caramel treats can be produced.

Owner:TIANJIN ALPHA HEALTH-CARE PROD CO LTD

Quick-frozen pan-fried pork buns and making method thereof

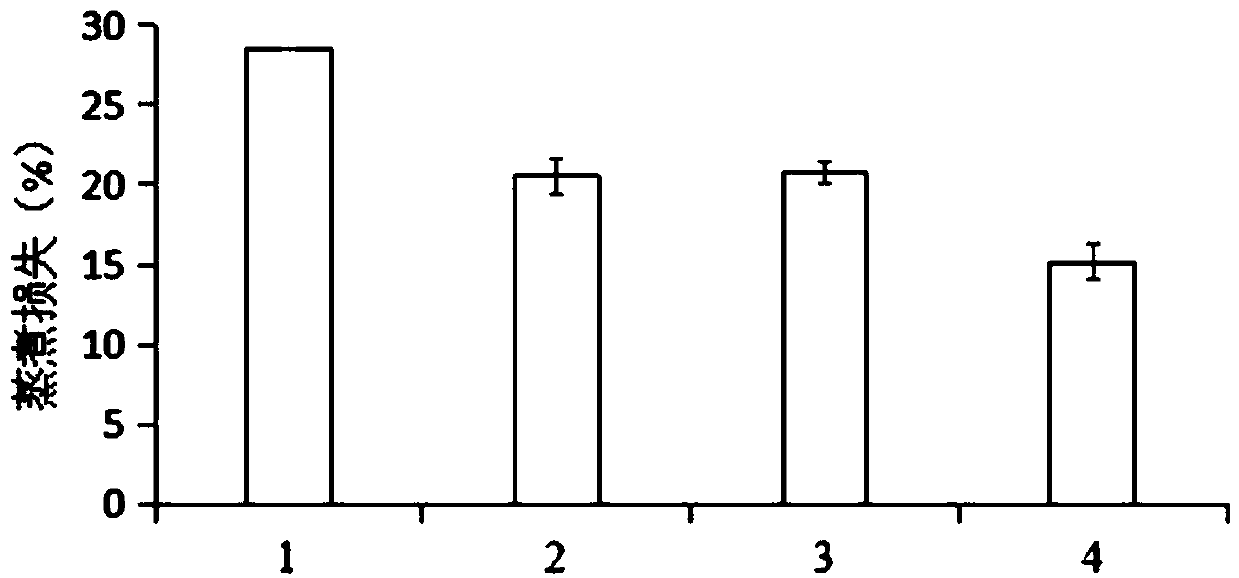

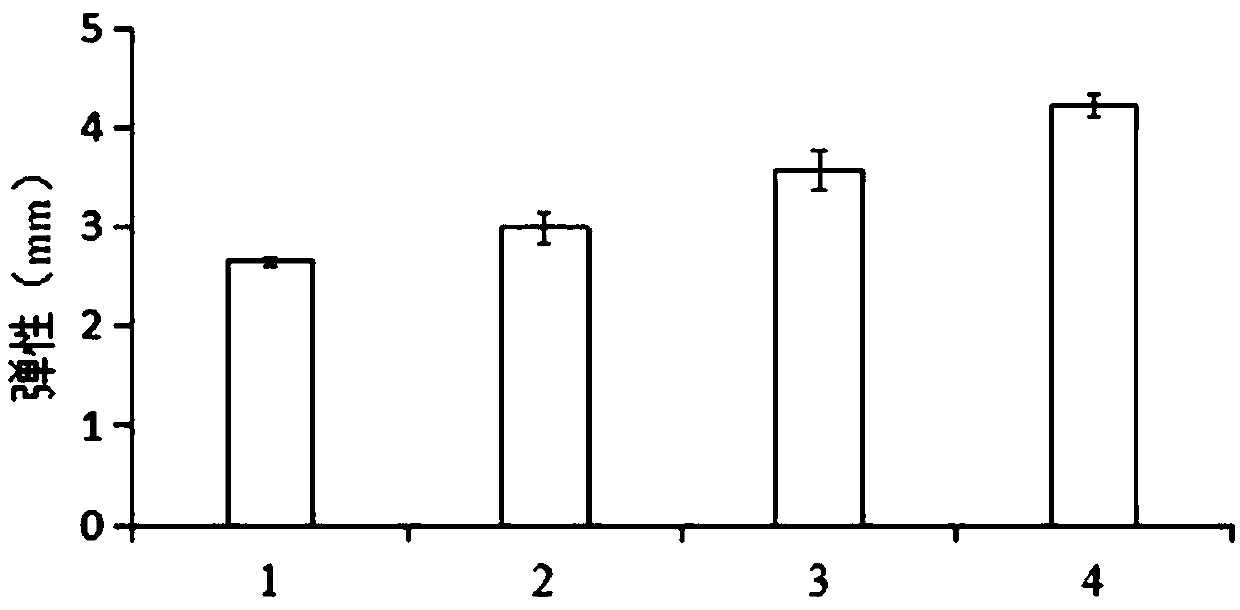

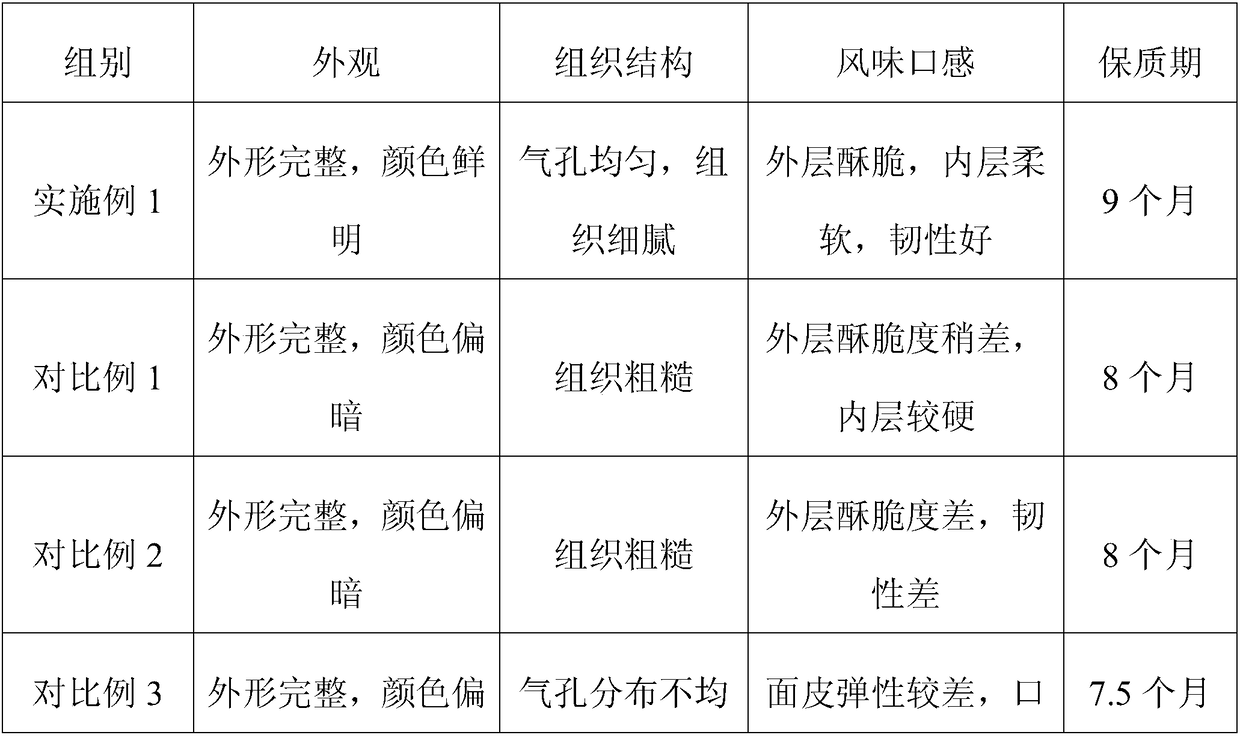

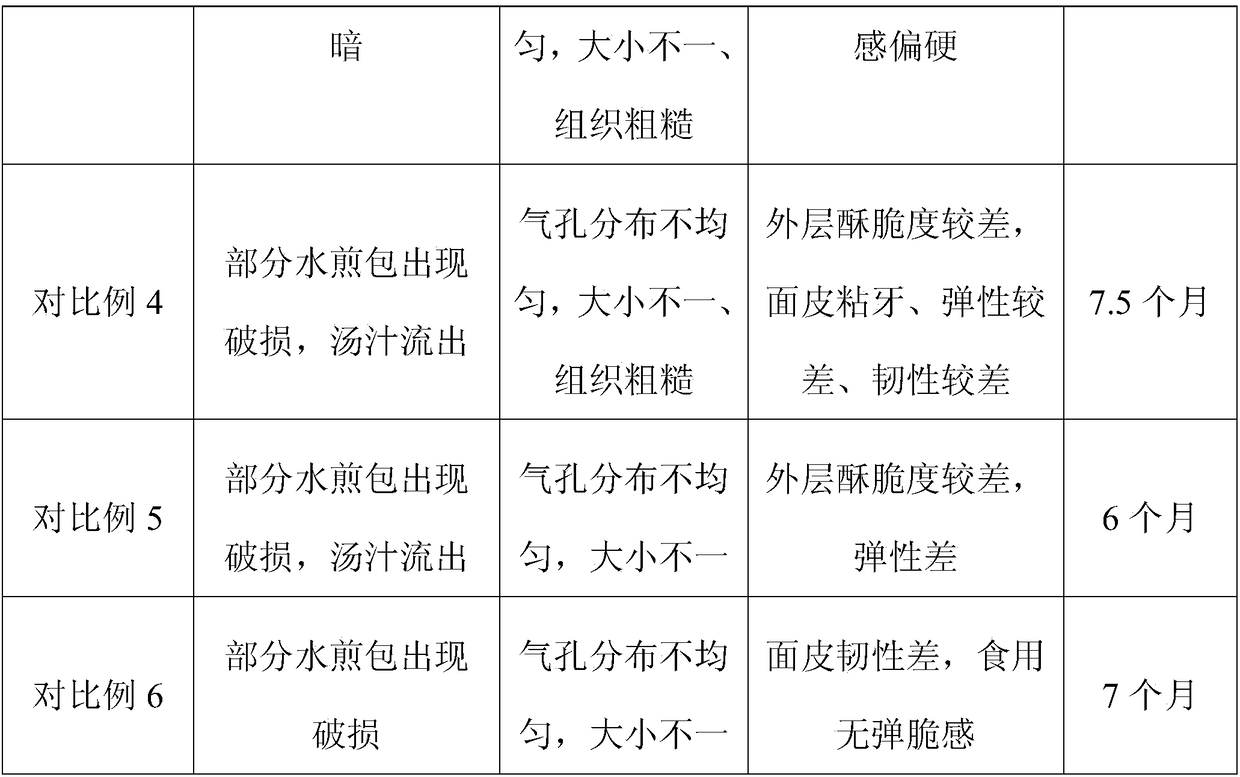

InactiveCN109480184AIncrease surface areaCrispy tasteFood freezingYeast food ingredientsGlutenBaking powder

The invention discloses quick-frozen pan-fried pork buns. The wrappers of the pan-fried pork buns comprise the following raw materials in parts by weight of 95-105 parts of medium-gluten flour, 0.15-0.35 part of yeast, 0.8-1.3 parts of white sugar, 0.3-0.5 part of baking powder, 0.8-1.3 parts of emulsified oil, 2-5 parts of lard, 0.2-0.4 part of a wrapper modifier and 51-54 parts of water. The wrapper modifier is added to the wrappers, so that the mouth feel of the wrappers can be notably improved, the stability can be improved, and the quality guarantee period can be prolonged. The inventionalso provides a making method of the quick-frozen pan-fried pork buns. Dough leavening is performed in a freezer, fermentation is performed in the freezer of 0-5 DEG C for one night, on the next day,the effect of half-leavened dough can be achieved, and the wrappers of the pan-fried pork buns can be tenacious and cannot retract; and dough is put in a pork bun making machine for shaping, secondaryleavening is not used, the pan-fried pork buns are directly put in a tunnel for quick-freezing, the technology is simplified and controllable, and the production efficiency is greatly improved.

Owner:河南创新研霖食品科技有限公司

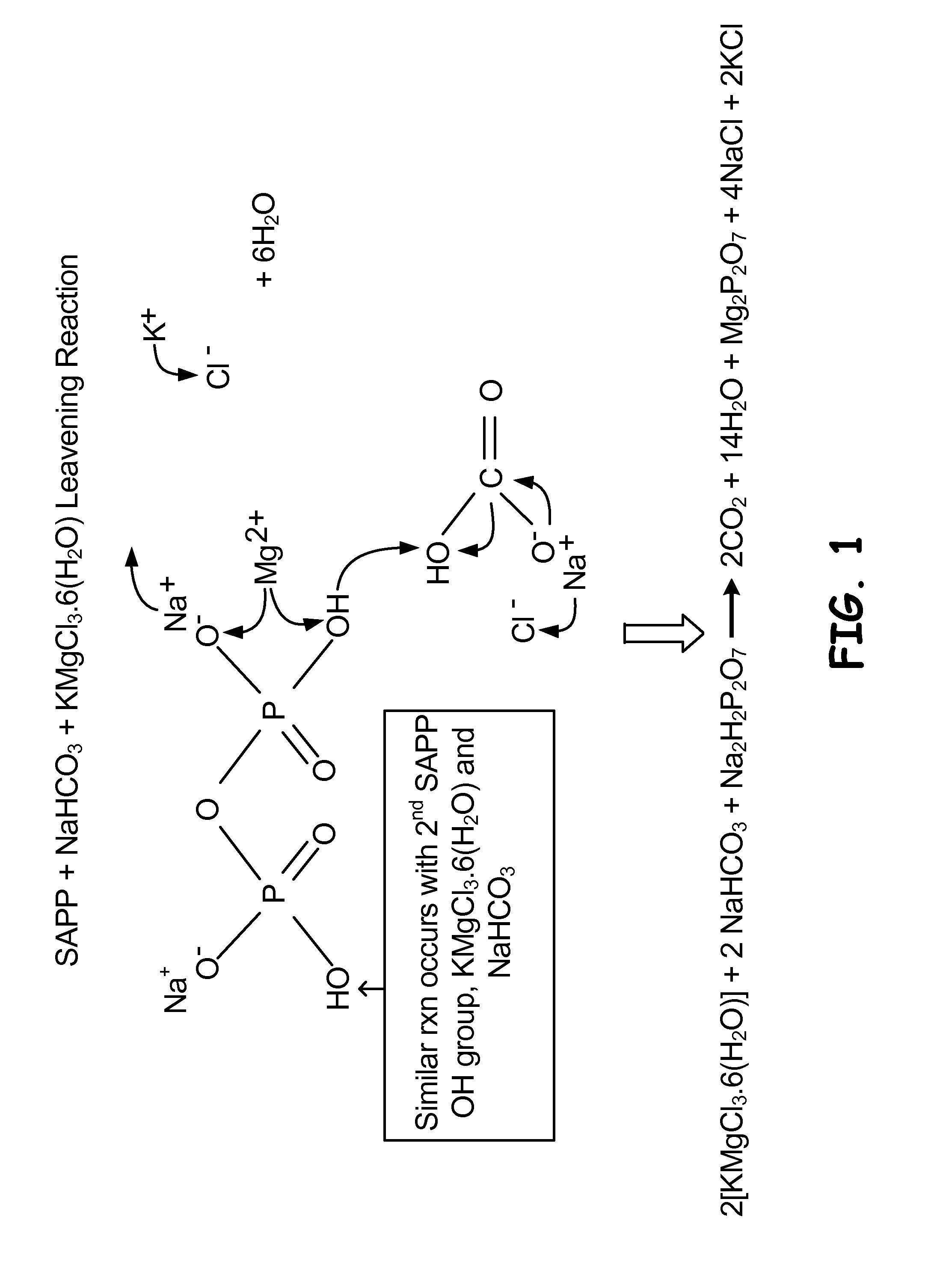

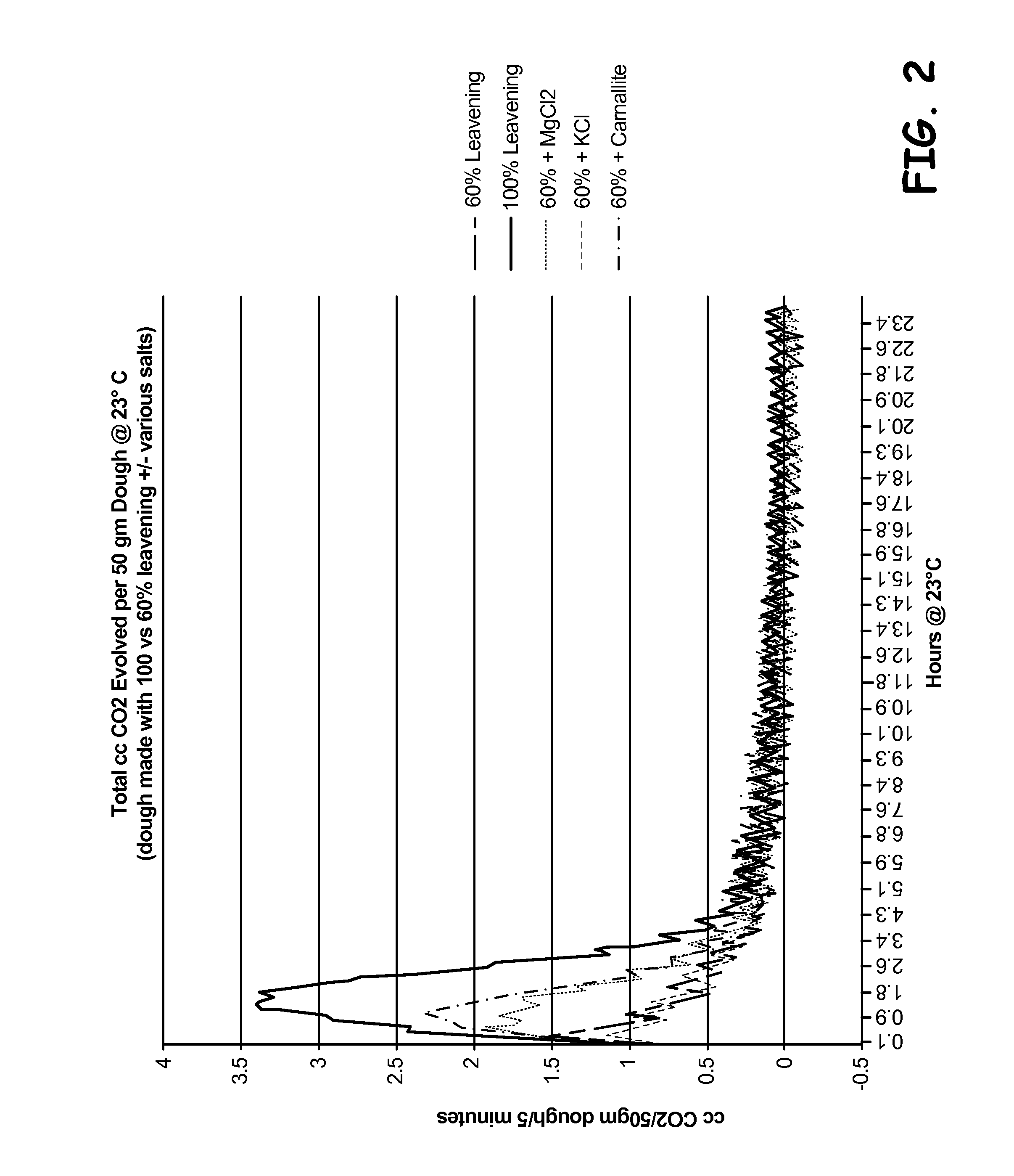

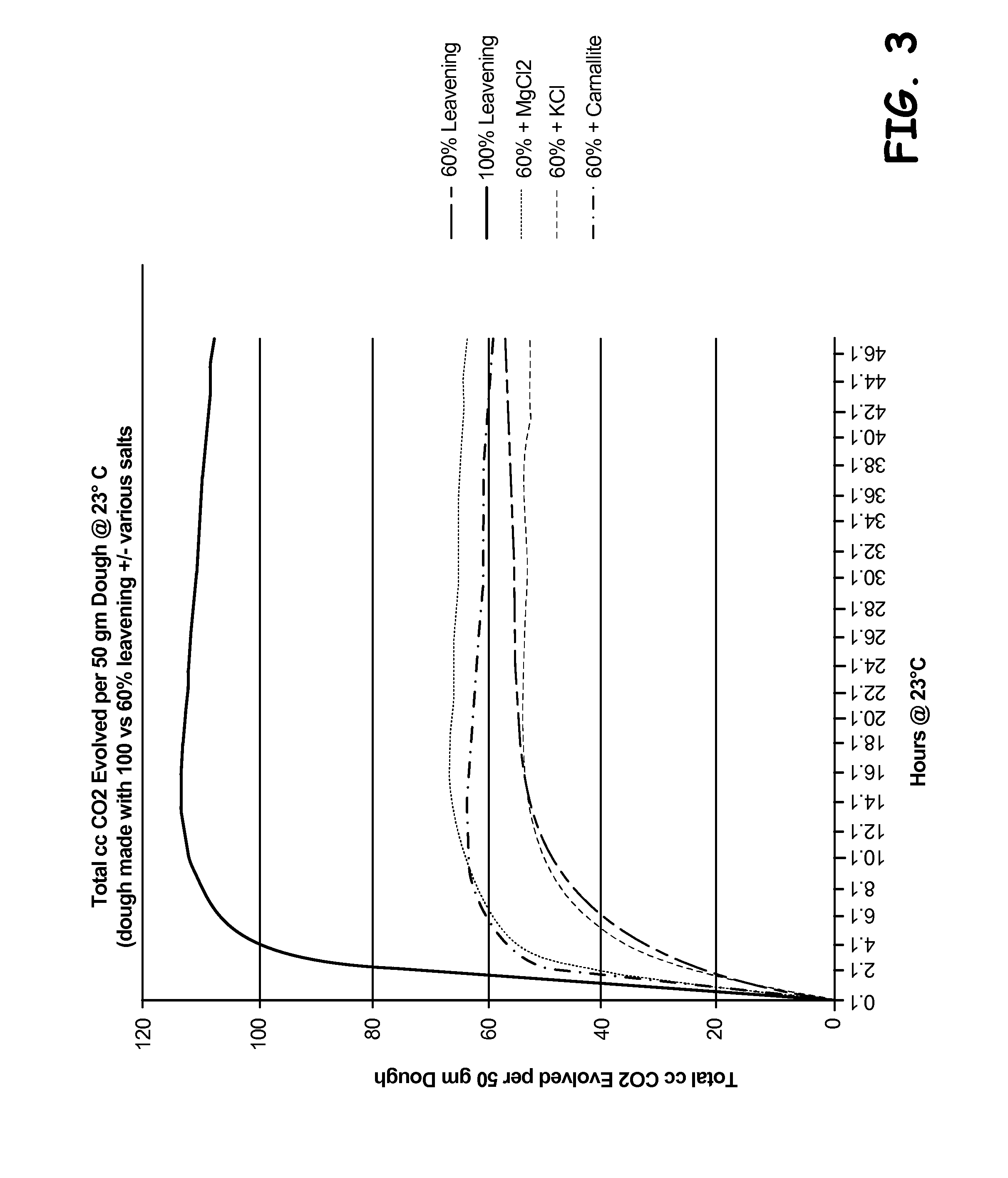

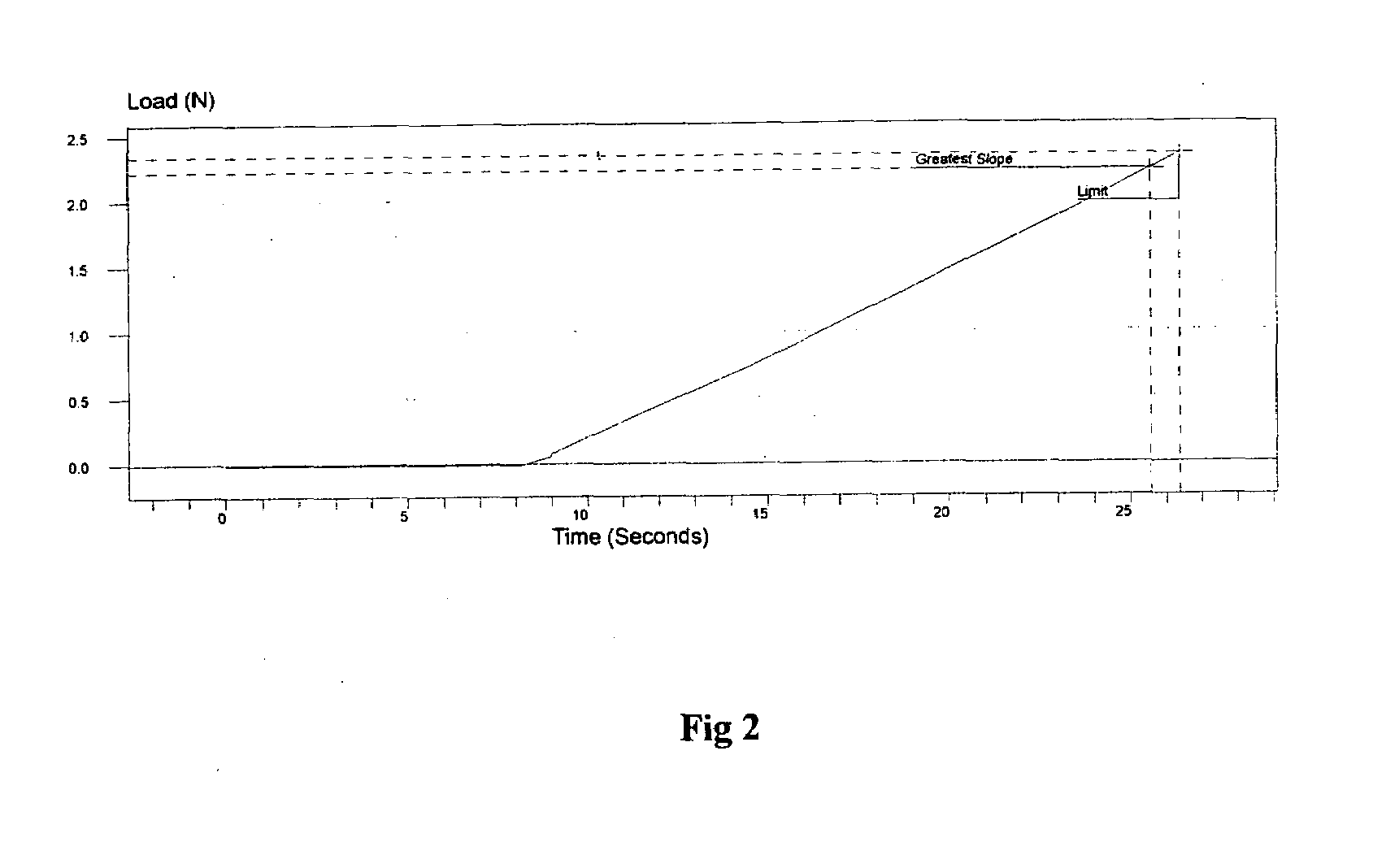

Method and system for regulating leavening reactions

ActiveUS20150132437A1Reduce probabilityLow electronegatvityReady-for-oven doughsMilk preparationAdditive ingredientReaction rate

A method and system for regulating the reaction rate of leavening agents in a dough product is described. The method and system include adding a regulating agent to a leavening system to manipulate the rate of reaction of the leavening agents in the dough. A method for preparing a chemically-leavened packaged or canned dough product by combining a chemical leavening agent and a regulating agent with the dough ingredients; placing the dough in a package; and allowing the leavening agent and regulating agent to react in the dough to generate a gas to expand the dough to substantially fill the package.

Owner:GENERAL MILLS INC

Whole egg replacing novel premix concentrate specially designed for cake and cake related products

InactiveUS20100040755A1Improve functionalityImprove solubilityDough treatmentBakery battersProtein isolateHydrolysate

A Whole egg replacing novel premix concentrate specially designed for cake and cake related products wherein the said premix comprises isolates of protein from gramineae family—10-30% with isolates of milk based protein ranging from 20-40% and in conjunction with the emulsifier ranging from 5-15%, leavening system ranging from 1-10%, stabilizers such as calcium, sodium, potassium salts at about 7-10% with filler as starch and starch hydrolyzates.

Owner:ADVANCED ENZYME TECH

Steak and making method thereof

InactiveCN109329761AImprove the meat quality improvement effectKeep freshFood ingredient as raising agentFood ingredient as coating agentPotato starchHot peppers

The invention provides a steak and a making method thereof. The steak is mainly composed of beef tenderloin, a pickling material and a pulp material in parts by weight. The pickling material consistsof the following raw materials: 1-2 parts of vanilla, 3-4 parts of sodium alginate, 2-3 parts of calcium chloride, 3-6 parts of hot peppers, 2-4 parts of gingers, 1-2 parts of Laurus nobilis, 2-4 parts of cloves, 1-3 parts of allspice, 0.5-1 part of garlic powder and 3-6 parts of pricklyash peels. The pulp material includes the following raw materials: 1-2 parts of vanilla, 5-8 parts of egg white,1-2 parts of baking powder, 6-14 parts of potato starch and 15-25 parts of wheat flour. The making method includes the following steps: Step 1: acid exhaustion; cooling the beef tenderloin for 18-20minutes, spraying sodium alginate solution, and carrying out acid exhaustion for 18-20 hours; Step 2: selecting 100-120 parts of beef tenderloin after acid exhaustion, and injecting 10-12 mL of papainsolution with a concentration of 0.1%-0.15% into the acid exhausted beef tenderloin; Step 3: pickling the beef tenderloin with the pickling material for 20-25 minutes by vacuum rolling and kneading;Step 4: making the beef tenderloin after rolling and kneading formed into a steak through a forming machine; and Step 5: wrapping the steak with a pulp material. The steak obtained by the making method is fresh and tender in meat texture.

Owner:安徽徽之润食品股份有限公司

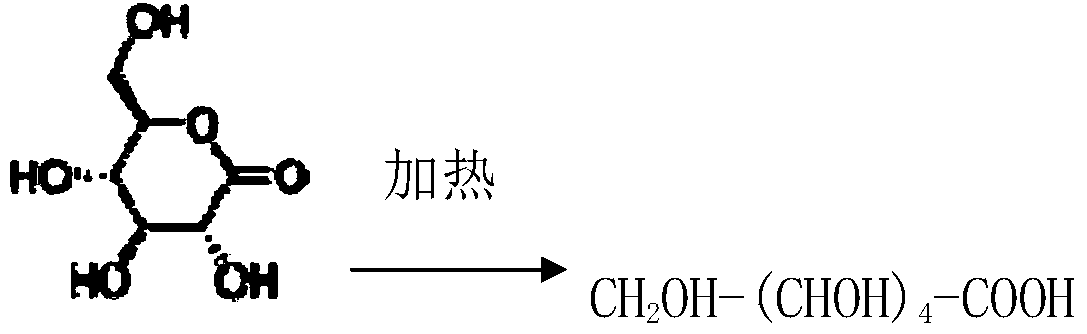

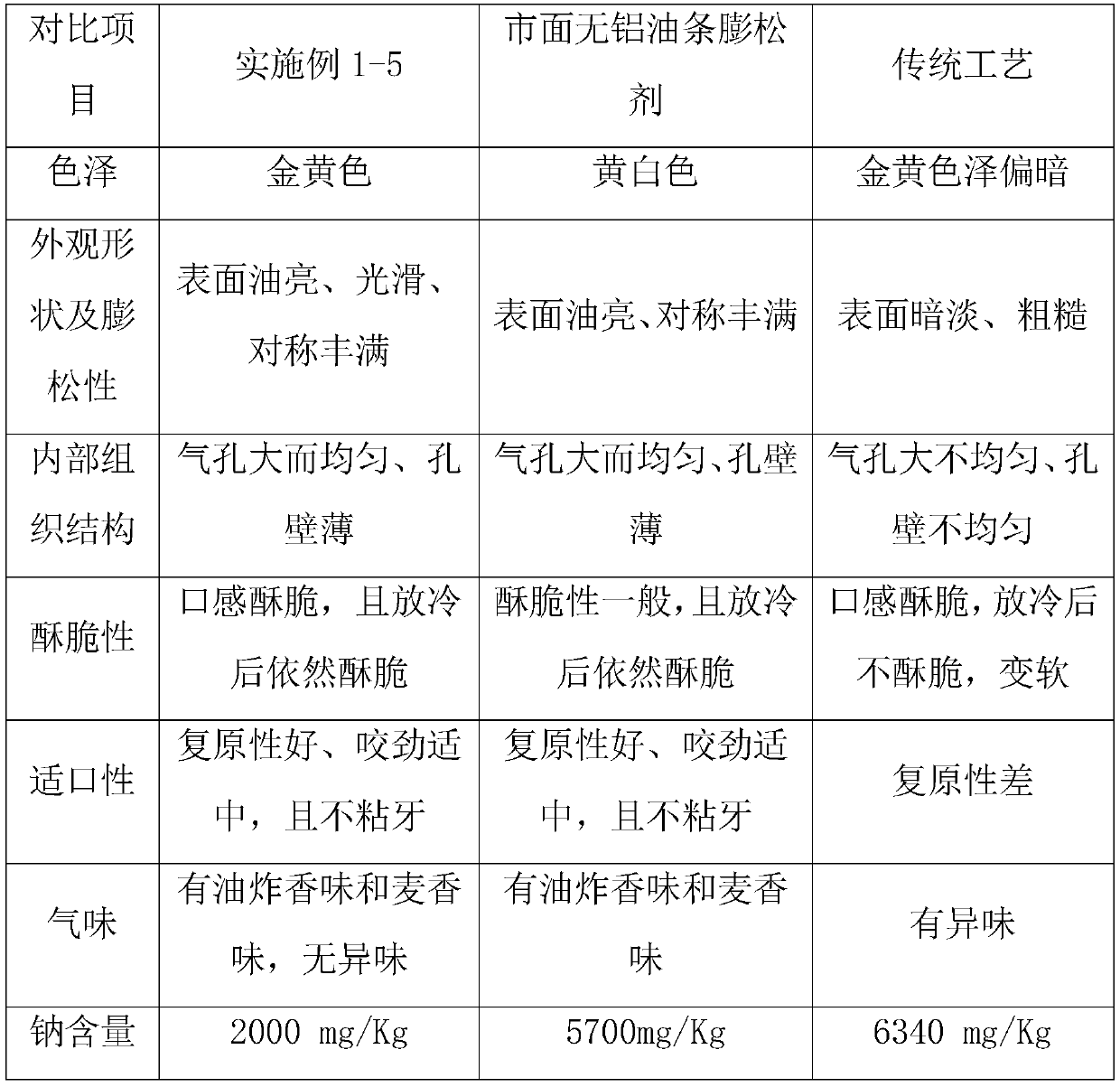

Composite phosphate aluminum-free quick leavening agent for deep-fried dough sticks, and preparation and use methods thereof

PendingCN111011429AEnsure food safetyReduce intakeDough treatmentFood ingredient as raising agentBiotechnologySodium bicarbonate

The invention discloses a composite phosphate aluminum-free quick leavening agent for deep-fried dough sticks. The composite phosphate aluminum-free quick leavening agent is prepared from the following raw materials in percentage by weight: 20-30% of sodium bicarbonate, 2-8% of calcium lactate, 13-15% of corn starch, 2-8% of gluconic acid-delta-lactone, 15-25% of acid calcium pyrophosphate, 10-20%of monocalcium phosphate, 10-20% of tricalcium phosphate and 0.5-1.5% of xylanase. A preparation method for the leavening agent provided by the invention comprises the following steps: drying the above raw materials at low temperature until a moisture content is less than 1%, crushing the raw materials, mixing the raw materials at 20-30 DEG C, and carrying out vacuumizing and packaging to obtainthe aluminum-free leavening agent for the deep-fried dough sticks. The aluminum-free leavening agent disclosed by the invention has low requirements on flour quality and techniques and is good in applicability, and the prepared deep-fried dough sticks are good in mouth feel. Due to the characteristics of no aluminum, low sodium, high calcium and the like, the eating safety and nutrition of the deep-fried dough sticks are ensured.

Owner:云南云天化以化磷业研究技术有限公司

Monkey food and preparation method thereof

InactiveCN109105645AImprove disease resistanceMaintain nutritional balanceFood processingFood ingredient as raising agentPhosphateVitamin

The invention relates to the field of feeds, and provides monkey food, which is prepared from the following components: 90 to 95 parts of a basic material, 3.5 to 4.5 parts of an animal premix, 0.15 to 0.25 part of a vitamin composition and 0.5 to 1 part of folic acid, wherein the vitamin composition comprises one or a combination of two of coated VC and VC phosphate. According to the monkey food,nutrients required by live monkeys can be provided, nutritional balance can be maintained, and the morbidity rate and the death rate can be reduced. The invention also provides a preparation method of the monkey food. By the preparation method, the monkey food specifically for providing the nutrients required by the live monkeys, maintaining nutritional balance and reducing the morbidity rate andthe death rate can be prepared.

Owner:江苏省协同医药生物工程有限责任公司

Octyltrimethylammonium chloride synergistic baking powder

InactiveCN103876004ARaw materials are easy to getLow costFood ingredient as raising agentFood preparationSodium bicarbonatePyrophosphate

The invention relates to octyltrimethylammonium chloride synergistic baking powder. The octyltrimethylammonium chloride synergistic baking powder is characterized by being prepared from the following components in parts by weight: 30-35 parts of sodium bicarbonate, 30-38 parts of disodium dihydrogen pyrophosphate, 5-10 parts of monocalcium phosphate, 20-25 parts of starch, 1-3 parts of calcium carbonate, 2-5 parts of citric acid, 2-5 parts of tartaric acid, 4-8 parts of glycerin monostearate, 1-2 parts of fumaric acid, 1-2 parts of distilled monostearin, 1-2 parts of octyltrimethylammonium chloride, 1-2 parts of sodium fatty acid methyl ester sulfonate, 1-2 parts of benzyl naphthalene sulfonic acid sodium, 1-2 parts of lecithin decanedioic acid, 1-2 parts of gluconic acid stearate-lactone, 1-2 parts of dioctyl sodium sulfate succinate, 1-2 parts of carboxymethylcellulose, 1-2 parts of tricresyl phosphate and 1-2 parts of sorbitan mo-nooleate and 1-2 parts of alginic acid and sodium diacetate. The octyltrimethylammonium chloride synergistic baking powder has the advantages that the raw materials are easily available, and the octyltrimethylammonium chloride synergistic baking powder is low in cost, convenient to use and good in effect, and is green.

Owner:李先兰

Self-rising dough-containing food product and related manufacturing methods

InactiveUS20090123607A1Desirable textureDesirable organoleptic propertyMilk preparationReady-for-oven doughsFood productsMoisture retention

A self-rising dough-containing food product, particularly pizza, in which a non-yeast containing leavening system is combined with an uncooked dough in the presence of a moisture retention agent and dough conditioners to provide a frozen raw food product that may be cooked directly from the freezer in a microwave oven. The dough in the self-rising dough containing food product reaches full development in shorter mixing times at lower mixing speeds than conventional dough-containing products.

Owner:INNOPHOS INC

Purple sweet potato Chinese chestnuts and processing method thereof

InactiveCN108464475AFull of nutritionSimple stepsFood ingredient as raising agentFood ingredient as coating agentFlavorSugar

The invention provides a processing method of purple sweet potato Chinese chestnuts and belongs to the field of food processing. The processing method comprises the following key links: material preparation, sugar cooking, powder blending, coating, baking, sterilizing and packaging. The processing method of the purple sweet potato Chinese chestnuts mainly utilizes machinery production, reduces manual labor, has simple steps, low processing cost and longer shelf life and is suitable for mass production. The prepared purple sweet potato Chinese chestnuts combine the flavor of Chinese chestnuts and purple sweet potatoes, have the advantages of crisp and delicious taste, rich nutrients and direct eating, and can better meet the requirements of people for diversified food tastes and nutritionaldiversity.

Owner:周雷

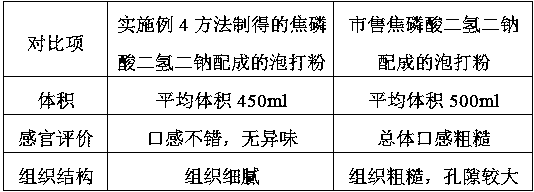

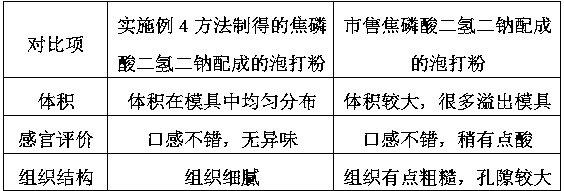

Preparation method of food-grade aluminum-free disodium dihydrogen pyrophosphate with low gas emission volume

InactiveCN108455549ASolve the problems of excessive volume, not delicate tissue structure and rough tasteSmooth breathingDough treatmentFood ingredient as raising agentPhosphatePotassium

The invention discloses a preparation method of food-grade aluminum-free disodium dihydrogen pyrophosphate with low gas emission volume. The preparation method comprises the following steps: filteringphosphoric acid and sodium hydroxide and regulating a temperature and concentration; adding phosphoric acid into a neutralization kettle, adding additives including calcium carbonate and potassium dihydrogen phosphate to obtain a mixture, and completely dissolving the mixture and then adding sodium hydroxide; controlling a reaction temperature and reaction end points after the sodium hydroxide solution is completely added, and curing to obtain a neutralized material; dropping the neutralized material into a powder spraying tower and performing powder spraying and drying to obtain anhydrous sodium dihydrogen phosphate powdery material; dropping the anhydrous sodium dihydrogen phosphate powdery material into a polyfurnace and performing polymerization, drying and sieving to prepare the aluminum-free disodium dihydrogen pyrophosphate with the low gas emission volume. According to the method disclosed by the invention, the additives including calcium carbonate and potassium dihydrogen phosphate are added, and the steps of the preparation method and parameters of the preparation method are optimized simultaneously, so that the problems that the size of a flour product made from disodium dihydrogen pyrophosphate is overlarge, a tissue structure is not exquisite and a taste is rough are solved, so that the products such as cakes and noodles are subjected to gas emission smoothly in aproduction process, the sizes of the products are uniform, the tissues are exquisite and the taste is superior.

Owner:连云港西都食品配料有限公司

Making technology of frozen raw steamed stuffed buns

PendingCN111296748ASolve quality problemsGreat tasteFood freezingYeast food ingredientsProcess engineeringGluten

The invention discloses a making technology of frozen raw steamed stuffed buns. The making technology comprises the steps of taking 1250 grams of medium-gluten flour, 10 grams of half-dried yeast, 50grams of white sugar, 80 grams of lard, 70 grams of aluminum-free baking powder and 700 grams of water, performing thorough mixing, performing dough mixing, performing leavening, performing dough pressing and making wrappers; using different materials, performing sufficient smashing and mixing, performing seasoning with scallions, ginger, corn oil, salt, sugar, oyster oil and sesame oil, forming pre-made meat fillings and bean curd fillings, and performing quick-freezing for storage; and unfreezing the fillings quick-frozen before, making uniform blocks through cooperation of an extruding machine and a rotary cutting machine, making steamed stuffed buns, and performing quick-freezing for preservation. After the steamed stuffed buns are processed by the steps of the method disclosed by theinvention, the mouth feel and the nutrient efficacy of finished products are greatly increased than those of traditional products; the raw steamed stuffed buns can be made into cooked steamed stuffedbuns through unfreezing and steaming once, the color, the filling flavor and the mouth feel of the steamed stuffed buns made by the making technology disclosed by the invention are compared favorablywith those of steamed stuffed buns which are fresh made, and the original flavor of the steamed stuffed buns can be reserved to the maximum extent.

Owner:吴江

Making method of fermented flour steamed buns

InactiveCN111011720AProduct stabilityImprove product qualityFood ingredient as raising agentLipidic food ingredientsBiotechnologyGlutenin

The invention relates to the technical field of food processing, in particular to a making method of fermented flour streamed buns, which comprises the following steps: making dough, fermenting for the first time, making alkaline dough, fermenting for the second time and steaming. According to the present invention, the temperature parameters and the humidity parameters of the two times of the fermentation are determined, a beta folding structure of the alcohol-soluble protein and the glutenin of the produced fermented flour steamed bun is increased, an alpha spiral structure and the beta corner content are reduced, and the elasticity, the resilience and the cohesiveness are higher than the commercially available fermented flour steamed bun; the method is high in mechanization degree, theprepared fermented flour steamed bun product is stable in quality, small in individual difference, clear in technological parameters and good in repeatability, the quality of the fermented flour steamed bun is improved, and development of steamed bun industrial production is promoted.

Owner:合肥市福客多快餐食品有限公司

Chicken cutlet preparation method and chicken cutlet

InactiveCN109329773AReduce dry consumptionIncrease moisture contentFood ingredient as raising agentMeat/fish preservation by coatingPinelliaPotato starch

The invention provides a Chicken cutlet preparation method and a chicken cutlet. The method comprises the following steps: acid removal: cooling slaughtered and cleaned chicken breast for 18-20 minutes, spraying a sodium alginate solution at a mass fraction of 1-2%, and conducting acid removal for 18-20 hours to obtain cold fresh chicken cutlet; pickling: putting the cutlet into a tumbling machinefor vacuum tumbling and pickling for 5-8 hours, wherein a pickling material corresponding to each 100 parts by weight of the chicken breast comprises the following raw materials in parts by weight: 1-2 parts of vanilla, 3-4 parts of sodium alginate, 2-3 parts of calcium chloride, 2-3 parts of chili powder, 3-4 parts of five-spice powder, 1-2 parts of chopped scallions, 1-2 parts of minced ginger,1-2 parts of minced garlic, 13-15 parts of sesame oil, 3-4 parts of pinellia tuber, 5-6 parts of dried orange peel, 2-3 parts of mint, 4-7 parts of honey and 1-2 parts of cassia seeds; and slurry coating: coating the pickled cold fresh chicken cutlet with slurry, wherein the slurry corresponding to each 100 parts by weight of the chicken breast comprises the following raw materials in parts by weight: 1-2 parts of vanilla, 5-8 parts of egg white, 1-2 parts of baking powder, 6-14 parts of potato starch and 15-25 parts of wheat flour. The chicken cutlet prepared by the Chicken cutlet preparation method has high water content and fresh and tender meat quality.

Owner:安徽徽之润食品股份有限公司

Areca nut substituent and preparation method thereof

InactiveCN107183636AThe length matchesMeet the tasteFood ingredient as raising agentFood ingredient as replacerFlavorFood material

The invention relates to the technical field of areca nut foods, and in particular relates to an areca nut substituent and a preparation method thereof. The preparation method comprises the following steps: A, preparing an areca nut concentrated solution; B, preparing areca nut sauce; C, preparing food materials: C1, washing the food materials and then cutting the food materials into blocks with the fiber length of 2cm to 6cm and the fiber width of 1cm to 3cm along the direction of food material fiber; C2, putting the cut block-shaped food materials into water with an added leavening agent and boiling; then heating and drying to prepare a fluffy dried product; D, seasoning the food materials; E, drying; F, shaping. According to the areca nut substituent prepared by the preparation method, the tissue fiber strength is very close to that of orginal areca nut fruits, so that the chewable property is ensured, and the flavor and mouthfeel of the orginal areca nut fruits are ensured; the effects of sweating and exciting are also sufficiently kept, and the areca nut substituent can be used as a substituent of the orginal areca nut fruit and products thereof, and has no damages, caused by traditional areca nuts, to oral cavities and teeth; the product has no residues after being eaten and is more environmentally friendly.

Owner:GUANGDONG GUANGYI TECH IND

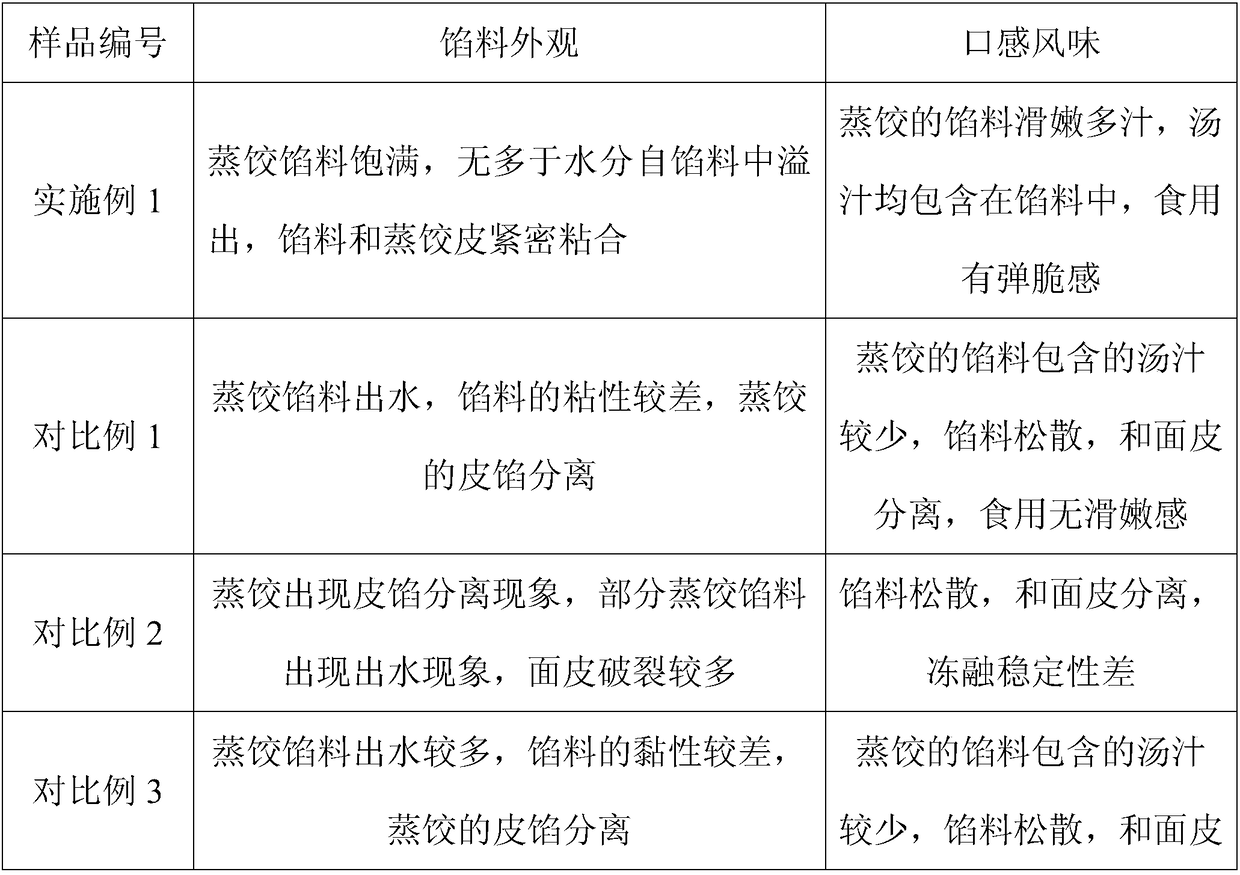

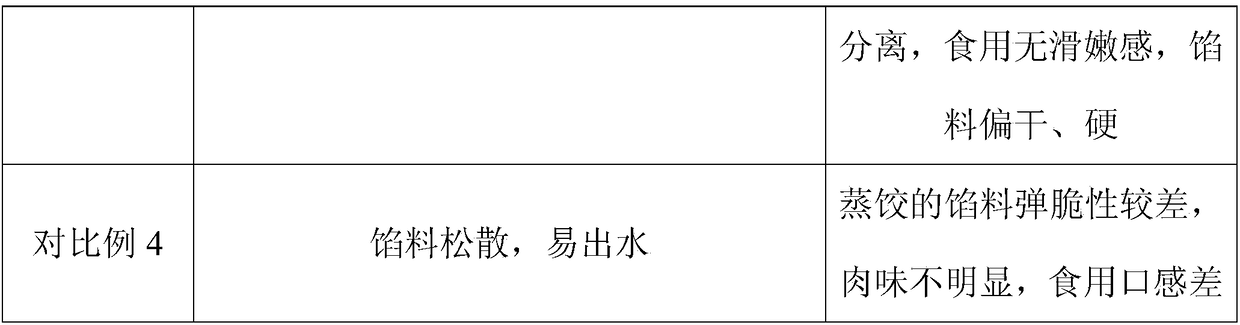

Steamed dumpling filling modifier, steamed dumplings and making method of steamed dumplings

InactiveCN109480175AImprove water retentionStrong stickinessFood ingredient as raising agentFood ingredient as mouthfeel improving agentChemistryHydroxypropyl distarch phosphate

The invention discloses a steamed dumpling filling modifier. The steamed dumpling filling modifier comprises the following raw materials in parts by weight of 60-68 parts of hydroxypropyl distarch phosphate, 25-35 parts of esterified crossbonded starch, 0.1-0.3 part of transglutaminase, 3-5 parts of composite phosphate and 1-3 parts of a composite leavening agent. According to the filling modifier, all components are in synergistic reaction, so that the water retention property and the stickiness of fillings can be improved, the tissue structure of meat quality is improved, and the eating mouth feel is smooth, tender, elastic and crisp. The invention further provides steamed dumplings. The steamed dumpling filling modifier is added to the fillings, so that shaping of the steamed dumplingsis facilitated, and the made steamed dumplings are plump and good in mouth feel. The invention further provides a making method of the steamed dumplings. The preparation method has the characteristicsof being simple, convenient and quick, and needs for industrialized batch production are met.

Owner:河南创新研霖食品科技有限公司

Making method of raw frozen steamed buns

InactiveCN104996898ARetain nutritionSolve productivityYeast food ingredientsFood ingredient as raising agentFlavorFrozen storage

The invention discloses a making method of raw frozen steamed buns. The making method comprises the following steps: a, uniformly mixing 500 parts by weight of flour and 5-8 parts by weight of baking powder so as to obtain a mixture, and then putting the mixture into a dough batch; b, putting 5-8 parts by weight of yeast, 6-10 parts by weight of an additive and 240-260 parts by weight of water into the dough batch, stirring the mixture, the yeast, the additive and the water for 8-10 minutes at a low speed, and then stirring the mixture, the yeast, the additive and the water for 10-15 minutes at a high speed so as to obtain dough; c, taking out the dough from the dough batch, repeatedly rolling the dough by a high-speed noodle press so as to obtain a strip, then cutting the strip into blocks, and putting the blocks in the environment of 30-40 DEG C for fermentation for 20-30 minutes; and d, rapidly freezing the fermented blocks in environment under minus 60 DEG C for 15-20 minutes, and then putting the blocks under the condition of the temperature of sub-zero 20 to sub-zero 15 for frozen storage, namely completing the making operation of the raw frozen steamed buns. Compared with the prior art, the making method of the raw frozen steamed buns, disclosed by the invention has the advantages that rapidly freezing the blocks in the environment under minus 60 DEG C can completely reserve the nutrition in the blocks, the raw frozen steamed buns can be eaten after being steamed once, and the flavor, the color and the mouth feel of the steamed raw frozen steamed buns can be compared favorably with those of the fresh steamed buns.

Owner:张璟 +2

Methods for Making Flour-Based Food Products and Food Products Made Thereby

ActiveUS20170027200A1Desirable textureDesirable tasteDough treatmentFood ingredient as raising agentMoistureWater content

The disclosure provides an improved process for making flour-based food products that have a final moisture content of less than 3%. In particular, the process comprises preparing uncooked dough from at least flour, starch, and water, heat-pressing the uncooked dough to form a heat-pressed dough sheet, and cooking the hot-pressed dough sheet to form a food product that has a final moisture content of less than about 3%. Advantageously, the food products can maintain a light, bubbly, and crisp texture with rapid mouthmelt.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

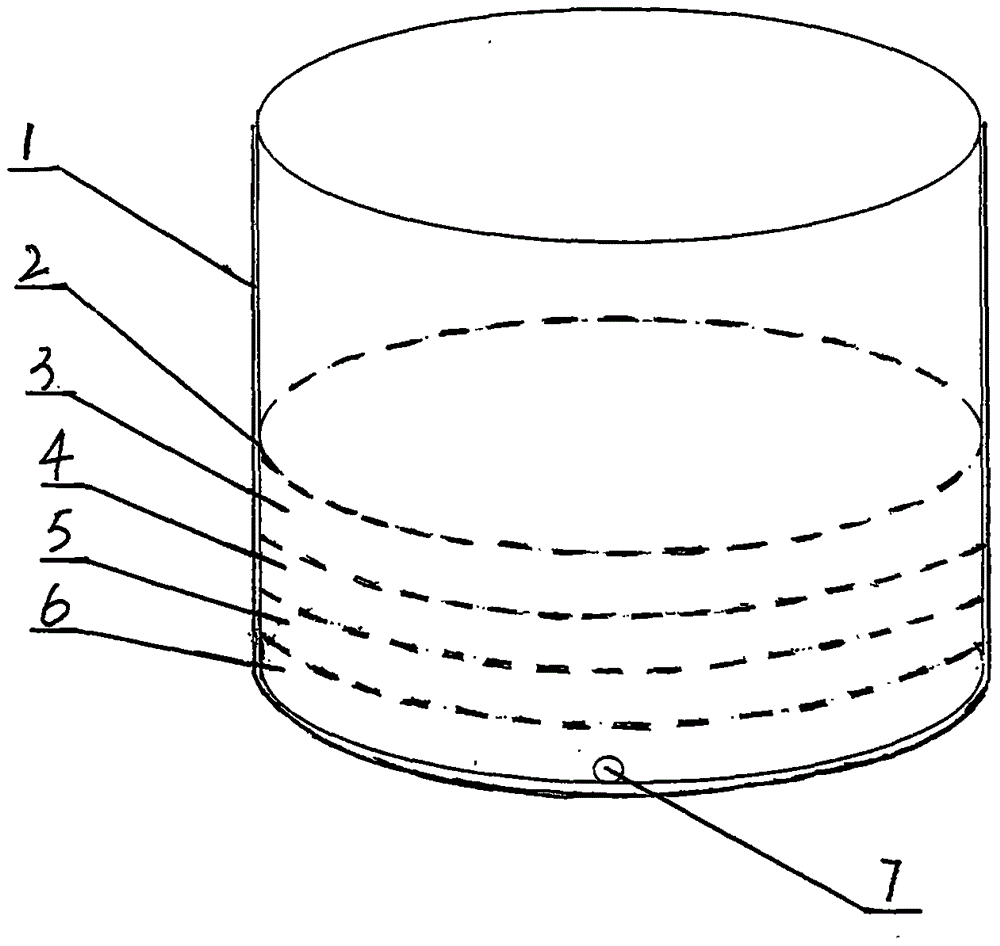

Preparation process of special leavening agent for quick-frozen foods

InactiveCN109601974AEasy to prepareImprove the quality of useFood ingredient as raising agentQuick FreezeChemistry

The invention discloses a preparation process of a special leavening agent for quick-frozen foods. The preparation process comprises the steps of weighing, pulverizing, stirring, mixing and drying toprepare the special leavening agent for the quick-frozen foods. The invention optimizes the preparation method of the leavening agent, and improves the use quality of the leavening agent; and the obtained leavening agent has large gas production, stable use, and uniform and fine foaming, effectively improves the taste and quality of the quick-frozen cooked wheaten food, and has great promotion andapplication value. The preparation process is very simple and has a wide range of applications.

Owner:南通寿星食品有限公司

Quick-frozen honey and grapefruit steamed cakes and preparation method thereof

InactiveCN105558816ASweet tasteRefreshing tasteFood freezingFood ingredient as raising agentPreservativeSugar

The invention relates to the technical field of food, and in particular relates to quick-frozen honey and grapefruit steamed cakes and a preparation method thereof. The quick-frozen honey and grapefruit steamed cakes are prepared from the following raw materials in percentage by weight: 35 to 45 percent of eggs, 20 to 30 percent of cake flour, 8 to 20 percent of white granulated sugar, 10 to 25 percent of grapefruit jam, 5 to 10 percent of edible oil, 3 to 6 percent of milk powder, 2 to 4 percent of an emulsifier, 1 to 3 percent of cheese, 0.1 to 0.3 percent of a swelling agent, and 0.1 to 0.3 percent of salt. The preparation method of the cakes comprises the following steps: performing stirring and leavening to prepare a paste material, then steaming the paste material, and performing quick freezing. The steamed cakes disclosed by the invention are integrated with sweet, sour and refreshing honey and grapefruit jam, so that the cakes taste more fragrant, sweet and refreshing, and have higher nutritional value. The preparation method disclosed by the invention greatly prolongs the storage period under the condition that no preservatives are added separately, and the problem of short storage life of the conventional steamed cakes is solved.

Owner:SANQUAN FOOD

Self-rising dough-containing food product and related manufacturing methods

InactiveCN101304661AReach full expansionShort mixing timeBakery product refreshing by heating/thawingReady-for-oven doughsMicrowave ovenEngineering

The present invention relates to a self-rising dough-containing food product, particularly pizza, in which a non-yeast containing leavening system is combined with an uncooked dough in the presence of a moisture retention agent and dough conditioners to provide a frozen raw food product that may be cooked directly from the freezer in a microwave oven. The dough in the self-rising dough containing food product reaches full development in shorter mixing times at lower mixing speeds than conventional dough-containing products.

Owner:INNOPHOS INC

Production apparatus and production method of all-natural highly-pure solid edible plant ash alkali

InactiveCN106422500AComply with the requirements of the use standardEasy to store and transportTransportation and packagingDissolving systemsHazardous substancePotassium

The invention relates to a production apparatus and production method of an all-natural highly-pure solid edible plant ash alkali. The production apparatus is a natural substance filter, and the natural substance filter comprises a porcelain filtering container with an open-ended superior surface, a gauze filtering layer, a quartz sand filtering layer, a palm sheet whisker filtering layer, a chicken feather vine filtering layer and a husk filtering layer. The production method comprises the following steps: sintering Schefflera arboicola with high potassium and sodium components, bamboo head and bamboo joint to form plant ash, enough placing the plant ash on the filtering layers in the porcelain filtering container, adding purified cold spring water to make the container be full of water in order to carry out dissolution and filtration, collecting filtered plant ash alkali water, removing crystal-containing turbid water at the bottom layer, pouring the plant ash alkali water into an iron pot, boiling the plant ash alkali water with strong fire until the plant ash alkali water is viscous, and stir-frying the viscous plant ash alkali water with moderate fire until a brown sugar-like solid is formed. A multiple filtering technology is adopted, and the filtering container and filtering layer substances are natural, so the filtered plant ash alkali water is all-natural and highly-pure; the purified cold spring water is adopted to carry out dissolution and filtration, so dissolution and introduction of impurities and harmful substances in the filtering layer substances into the above product at a high temperature are prevented; and the product is solid, and is convenient to transport and store.

Owner:张开基 +2

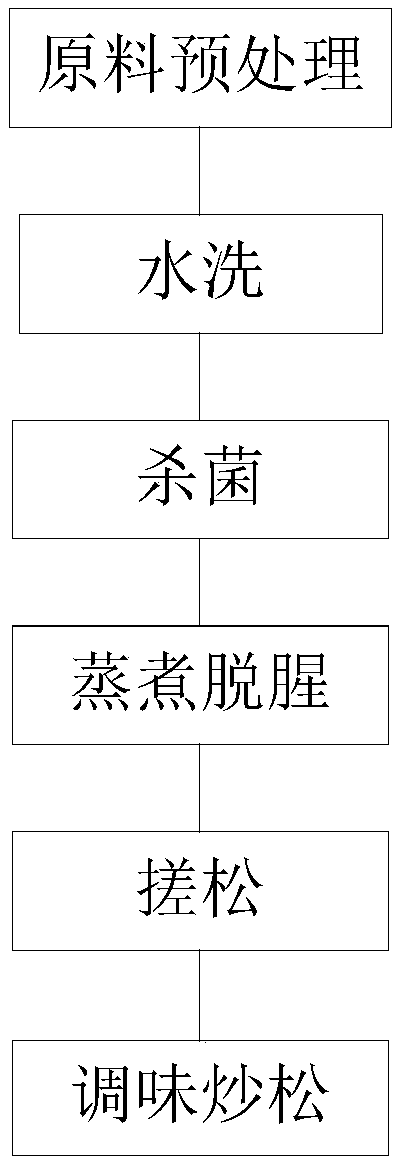

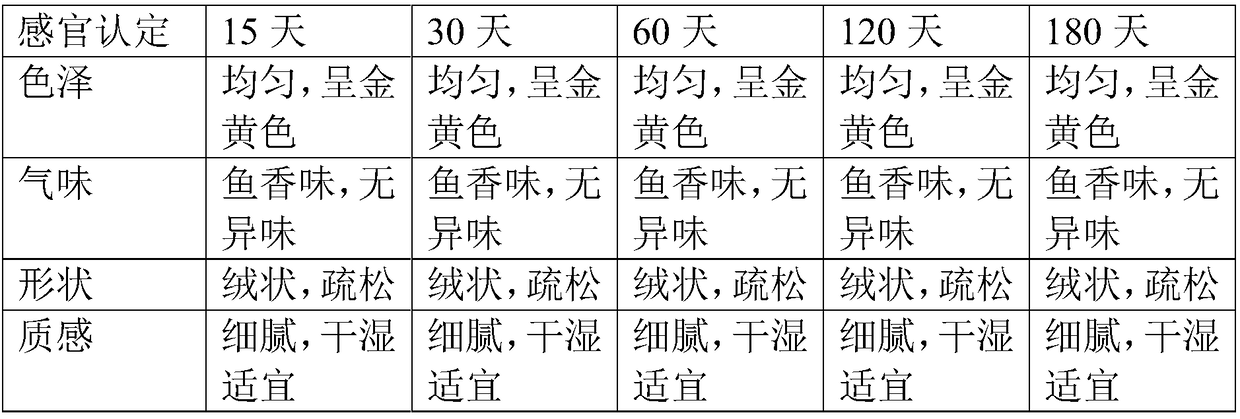

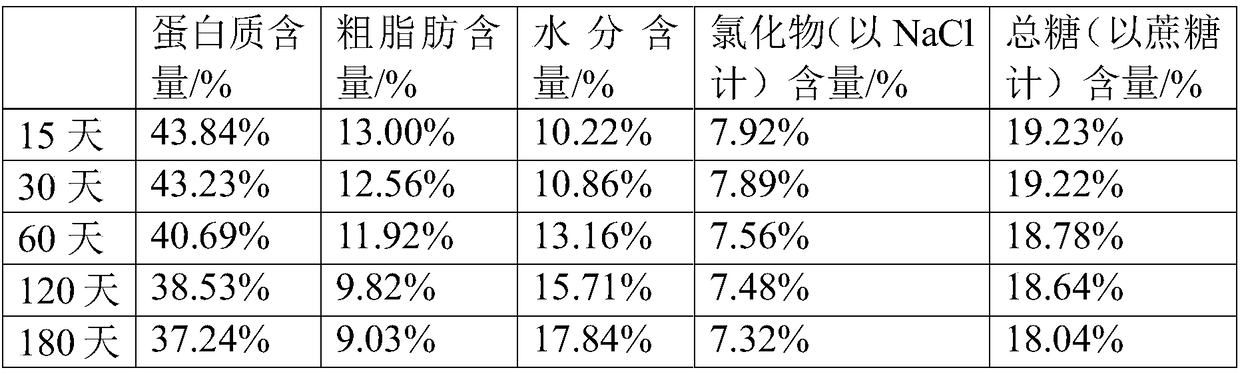

Tilapia floss and preparation method thereof

InactiveCN109452576AImprove antioxidant capacityPrevent oxidationFood ingredient as antioxidantFood ingredient as raising agentFlavorMonoglyceride citrate

The invention discloses tilapia floss and a preparation method thereof. The preparation method comprises the following steps: raw materials pretreatment, washing with water, sterilizing, steaming to remove fishy smell, rubbing and loosening, and seasoning and floss stir-frying. In the process of seasoning and floss stir-frying, a silicon dioxide-carotenoid cross-linking agent, monoglyceride citrate and a leavening agent are added, the net structure of the silicon dioxide-carotenoid cross-linking agent is effectively utilized to wrap the fish protein of the fish floss so as to form a layer of antioxidant membrane structure on the surface of the fish protein, and monoglyceride citrate used for reducing carotenoid is adsorbed on the antioxidant membrane structure, so that the antioxidant period is effectively prolonged, the shelf life of the finished fish floss product is prolonged, and the flavor and the quality of the fish floss are not influenced by the environmental conditions and thestorage time of the fish floss product.

Owner:江苏省徐州医药高等职业学校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com