Production apparatus and production method of all-natural highly-pure solid edible plant ash alkali

An edible plant, high-purity technology, applied in chemical instruments and methods, food science, dissolution methods, etc., can solve the problems of low product purity, many impurities, easy foaming, etc., and achieves wide medical uses, convenient transportation and storage, and taste Smooth and crisp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

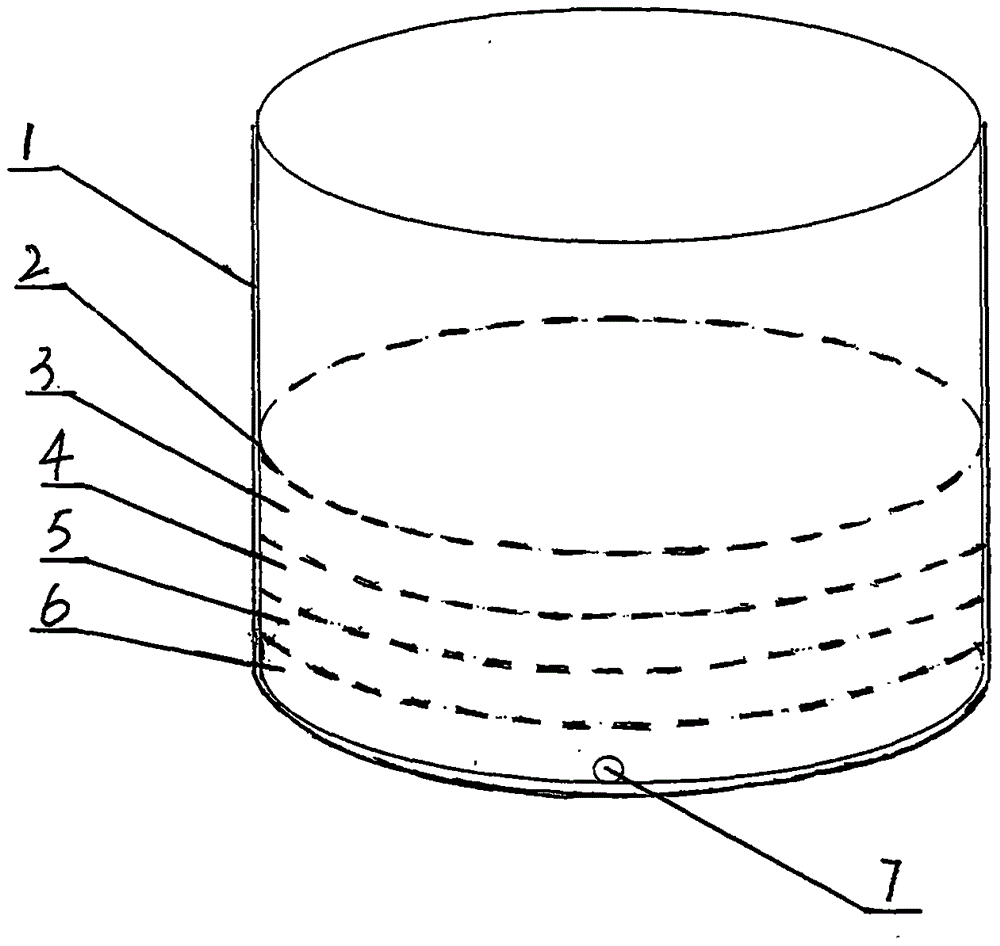

[0012] according to figure 1 Shown, a kind of embodiment of all-natural high-purity solid edible plant ash alkali production method and facility of the present invention is:

[0013] The all-natural high-purity solid edible plant ash alkali production facility of the present invention is a natural material filter, and the natural material filter consists of a porcelain filter container 1 with an opening above, a gauze filter layer 2, a quartz sand filter layer 3, and a palm whisker filter layer 4 , feather rattan filter layer 5, chaff filter layer 6, porcelain filter container 1 is provided with an outlet pipe 7 on the bottom side, and clean chaff, feather rattan, palm whiskers, and quartz sand are laid in layers from bottom to top In the porcelain filter container 1, gauze is covered on the quartz sand, and a gauze filter layer 2, a quartz sand filter layer 3, a palm whisker filter layer 4, and a feather vine filter layer 5 are formed in the porcelain filter container 1 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com