Making method of raw frozen steamed buns

A production method and technology of steamed buns, which are applied in food preparation, functions of food ingredients, and food ingredients as fluffing agents, etc., can solve the problems of loss of nutrients, flavor and taste of steamed buns, etc., so as to ensure no loss, taste and nutrition Composition, solution to the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for making raw and frozen steamed buns, comprising the following steps:

[0025] a. Mix 500g flour and 5g baking powder evenly, then put it into the dough maker;

[0026] b. Put 5g of yeast, 3g of antifreeze yeast, 3g of glycerophospholipid and 240g of water into the dough maker, stir slowly for 8 minutes, add 1.5g of dehydrated edible oil, then stir quickly for 10 minutes, and then make dough;

[0027] c. After taking out the dough, use a high-speed noodle machine to repeatedly roll it into strips, then roll the strips on the table, cut the strips into noodle blocks, and then put the noodle blocks in an environment of 30°C for 30 minutes, and the humidity is controlled at 80%. ;

[0028] d. Quickly freeze the proofed noodle blocks at -61°C for 20 minutes. After the center temperature of the noodle blocks drops to the ambient temperature in the freezer, put the noodle blocks into freezing storage at -20°C to complete production. Production of frozen buns.

Embodiment 2

[0030] A method for making raw and frozen steamed buns, comprising the following steps:

[0031] a. Mix 500g flour and 8g baking powder evenly, then put it into the dough maker;

[0032] b. Put 8g of yeast, 5g of antifreeze yeast, 5g of glycerophospholipid and 260g of water into the dough maker, stir slowly for 10 minutes, add 2.5g of dehydrated edible oil, then stir quickly for 15 minutes, and then make dough;

[0033] c. After the dough is taken out, use a high-speed noodle machine to repeatedly roll it into strips, then roll the strips on the table, cut the strips into noodle blocks, and then put the noodle blocks in an environment of 40°C for 20 minutes, and the humidity is controlled at 60%. ;

[0034] d. Quickly freeze the proofed noodle blocks at -70°C for 15 minutes. After the center temperature of the noodle blocks drops to the ambient temperature in the freezer, put the noodle blocks into storage at -15°C to complete production. Production of frozen buns.

Embodiment 3

[0036] A method for making raw and frozen steamed buns, comprising the following steps:

[0037] a. Mix 500g flour and 6.5g baking powder evenly, then put it into the dough maker;

[0038] b. Put 6.5g of yeast, 4g of antifreeze yeast, 4g of glycerophospholipid and 250g of water into the dough maker, stir slowly for 9 minutes, add 2g of dehydrated edible oil, then stir quickly for 12 minutes, and then make dough;

[0039] c. After taking out the dough, use a high-speed noodle machine to repeatedly roll it into strips, then roll the strips on the table, cut the strips into noodle blocks, and then place the noodle blocks at 35°C for 25 minutes, and control the humidity at 70%. ;

[0040] d. Quickly freeze the proofed noodle pieces at -65°C for 18 minutes. After the center temperature of the noodle pieces drops to the ambient temperature in the freezer, put the noodle pieces into freezing storage at -18°C to complete production. Production of frozen buns.

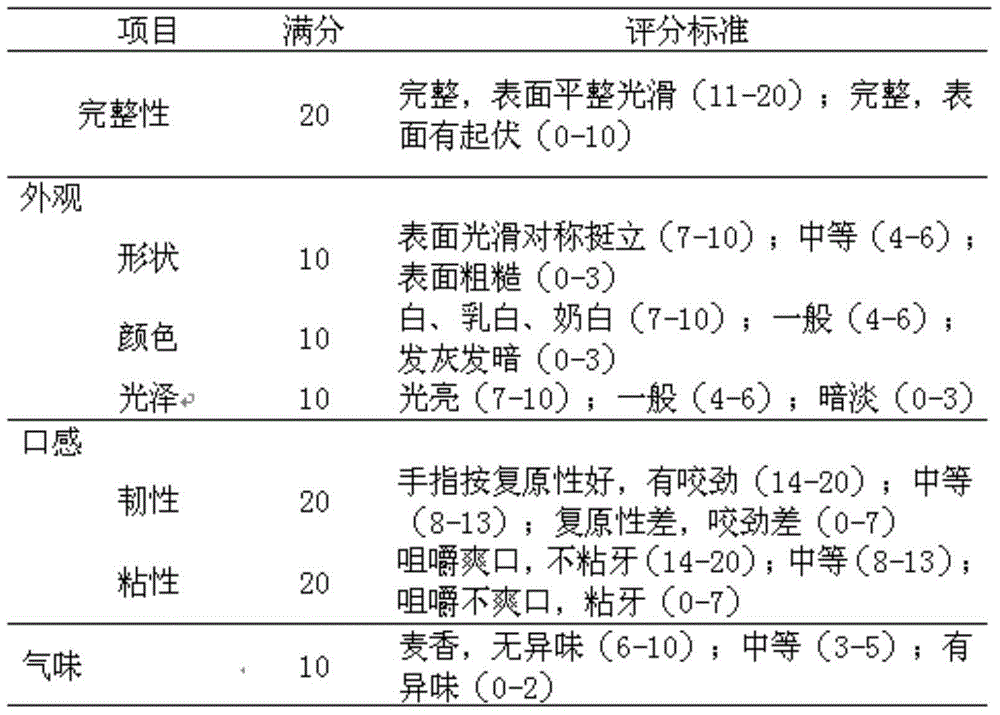

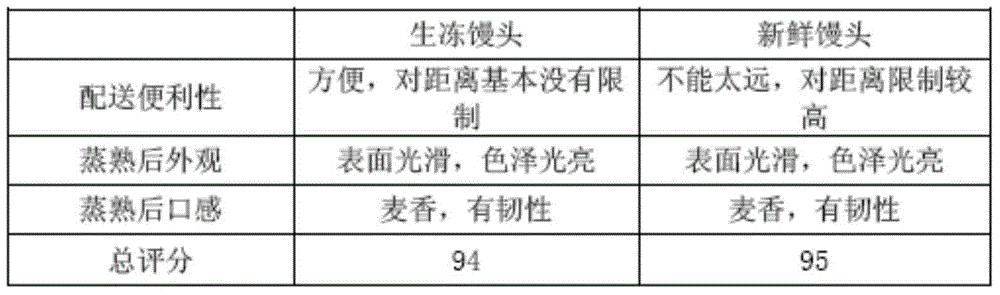

[0041] The raw and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com