Preparation process of special leavening agent for quick-frozen foods

A technology of quick-frozen food and preparation technology, which is applied in the direction of food ingredients as bulking agent, food ingredients, application, etc. It can solve the problems that calcium cannot be fully absorbed, utilized, divided into goiter, and tooth loss, etc., to improve the taste and quality of food , The preparation process is simple, the foaming effect is uniform and fine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

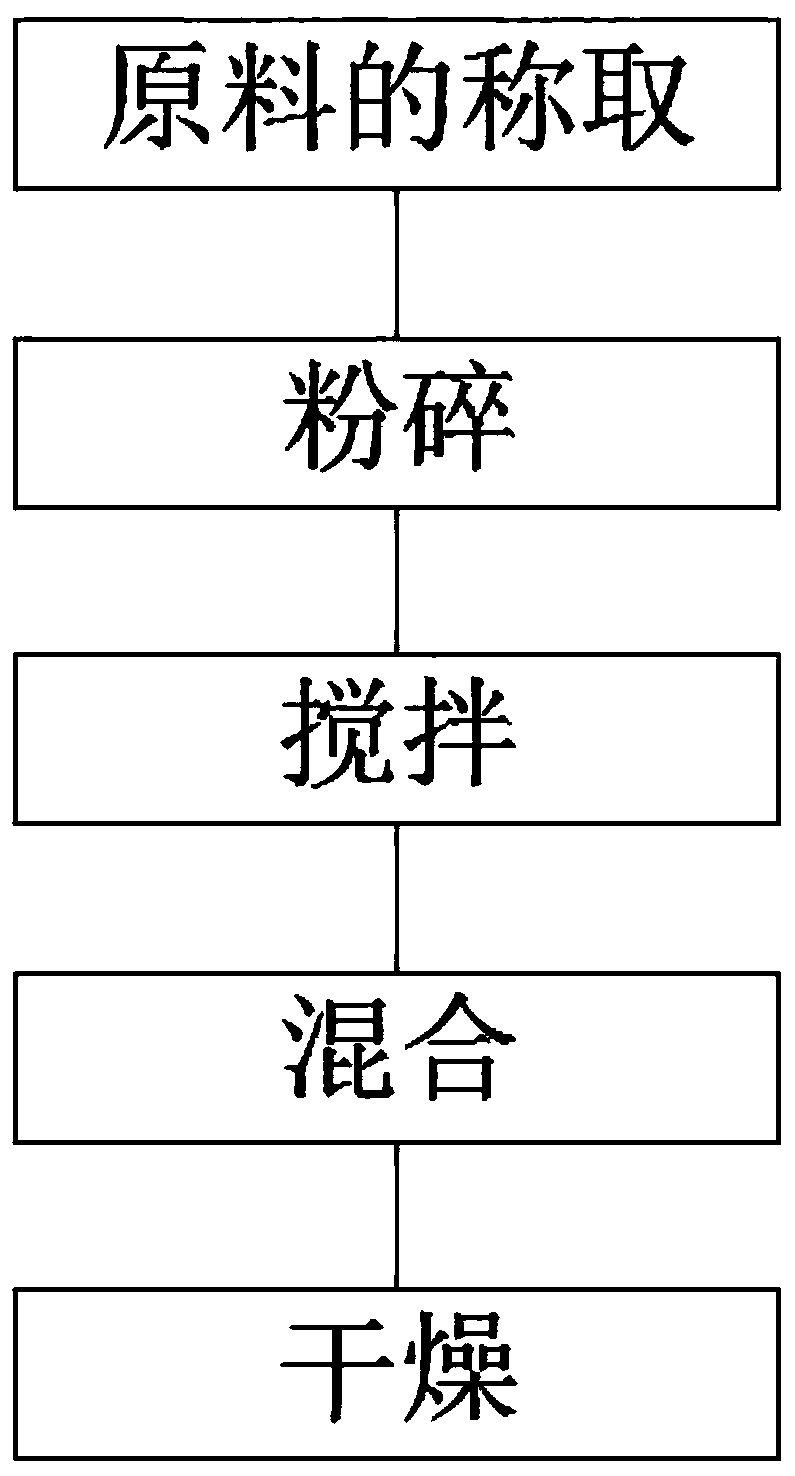

[0022] A preparation process of a special leavening agent for quick-frozen food, through the steps of weighing, crushing, stirring, mixing and drying of raw materials, the preparation of the special leavening agent for quick-frozen food is completed; the specific steps are as follows:

[0023] (1) Weighing of raw materials: select the following raw materials by weight: 14 parts of glucono-δ-lactone, 4 parts of sodium dihydrogen phosphate, 3 parts of sodium tripolyphosphate, 30 parts of sodium bicarbonate, 4 parts of citric acid, 1 part malic acid, 4 parts table salt, 30 parts oxidized hydroxypropyl starch, 4 parts prolamin and 3 parts carrageenan, 2 parts tartaric acid, 1 part potassium hydrogen tartrate and 3 parts potassium aluminum sulfate;

[0024] (2) Pulverization: The weighed sodium dihydrogen phosphate, sodium tripolyphosphate, sodium bicarbonate, citric acid, malic acid, tartaric acid, potassium hydrogen tartrate and potassium aluminum sulfate are put into the superfin...

Embodiment 2

[0029] A preparation process of a special leavening agent for quick-frozen food, through the steps of weighing, crushing, stirring, mixing and drying of raw materials, the preparation of the special leavening agent for quick-frozen food is completed; the specific steps are as follows:

[0030] (1) Weighing of raw materials: select the following raw materials in parts by weight: 16 parts of glucono-δ-lactone, 8 parts of sodium dihydrogen phosphate, 5 parts of sodium tripolyphosphate, 38 parts of sodium bicarbonate, 6 parts of citric acid, 3 parts of malic acid, 28 parts of table salt, 40 parts of oxidized hydroxypropyl starch, 8 parts of prolamine and 6 parts of carrageenan, 6 parts of tartaric acid, 5 parts of potassium hydrogen tartrate and 6 parts of potassium aluminum sulfate;

[0031] (2) Pulverization: The weighed sodium dihydrogen phosphate, sodium tripolyphosphate, sodium bicarbonate, citric acid, malic acid, tartaric acid, potassium hydrogen tartrate and potassium alumi...

Embodiment 3

[0036] A preparation process of a special leavening agent for quick-frozen food, through the steps of weighing, crushing, stirring, mixing and drying of raw materials, the preparation of the special leavening agent for quick-frozen food is completed; the specific steps are as follows:

[0037] (1) Weighing of raw materials: select the following raw materials in parts by weight: 15 parts of glucono-δ-lactone, 6 parts of sodium dihydrogen phosphate, 4 parts of sodium tripolyphosphate, 34 parts of sodium bicarbonate, 5 parts of citric acid, 2 parts of malic acid, 16 parts of table salt, 35 parts of oxidized hydroxypropyl starch, 6 parts of prolamine and 4.5 parts of carrageenan, 4 parts of tartaric acid, 3 parts of potassium hydrogen tartrate and 4.5 parts of potassium aluminum sulfate;

[0038] (2) Pulverization: The weighed sodium dihydrogen phosphate, sodium tripolyphosphate, sodium bicarbonate, citric acid, malic acid, tartaric acid, potassium hydrogen tartrate and potassium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com