Leaf lard remover

A technology of suet and starter, applied in the direction of slaughtering accessories, devices for removing viscera, cleaning intestines, etc., can solve the problems of time-consuming, long time-consuming, slow-down of processing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

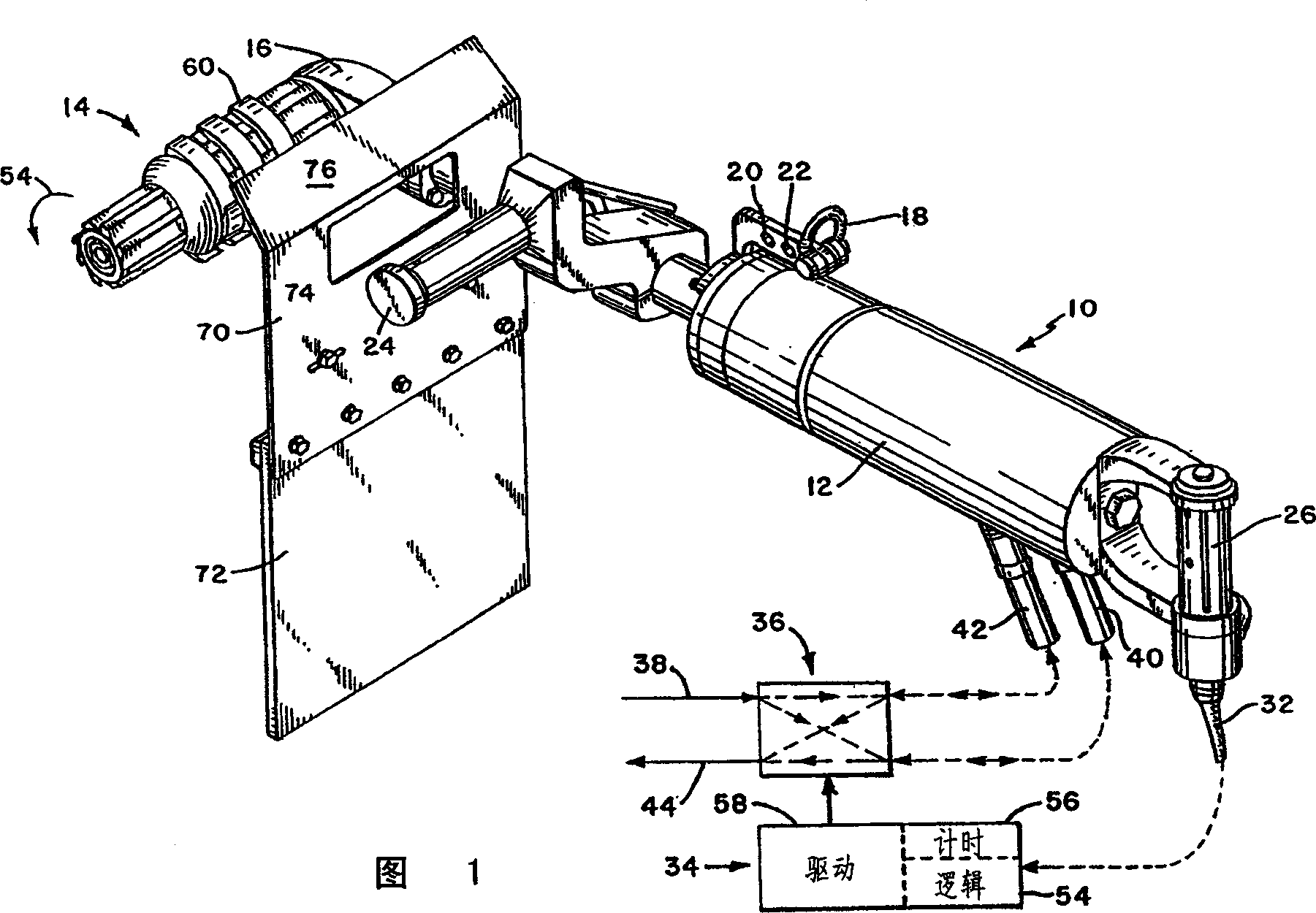

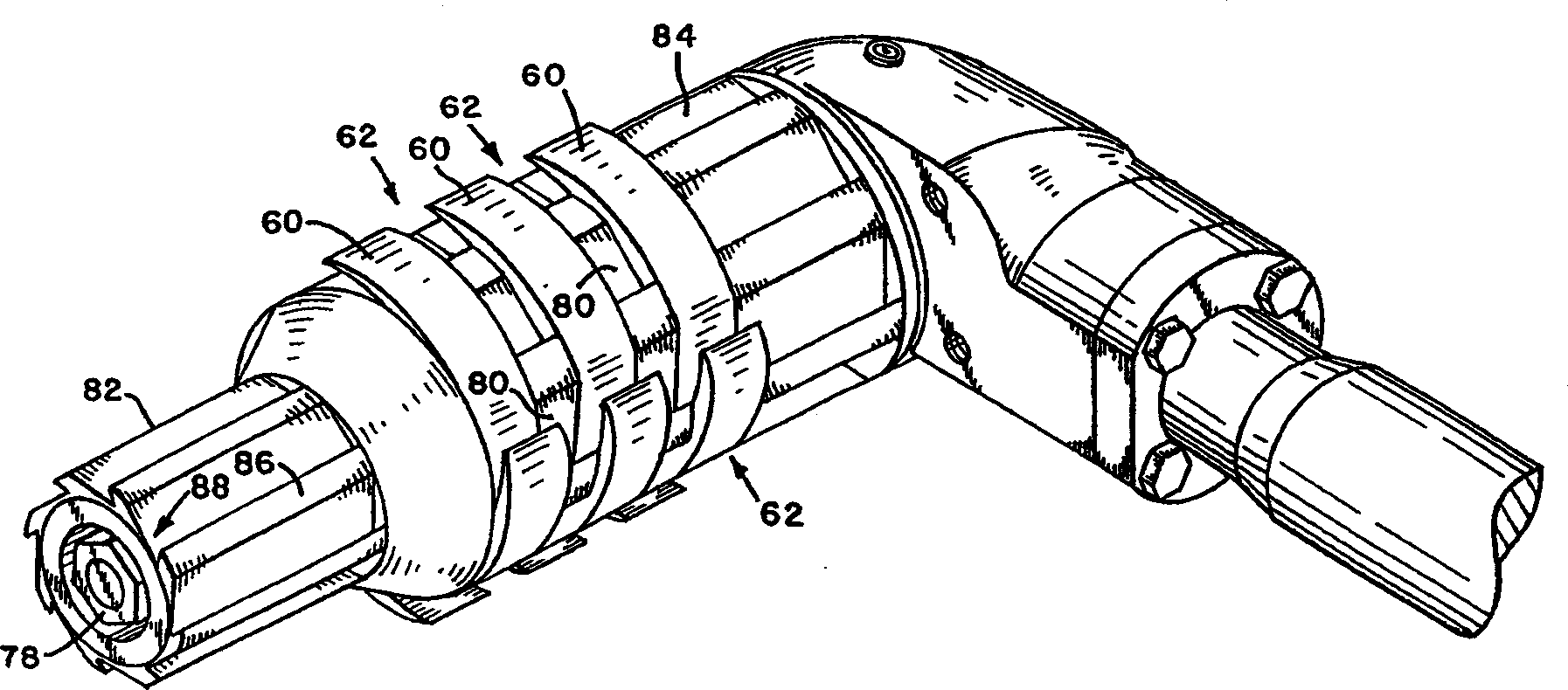

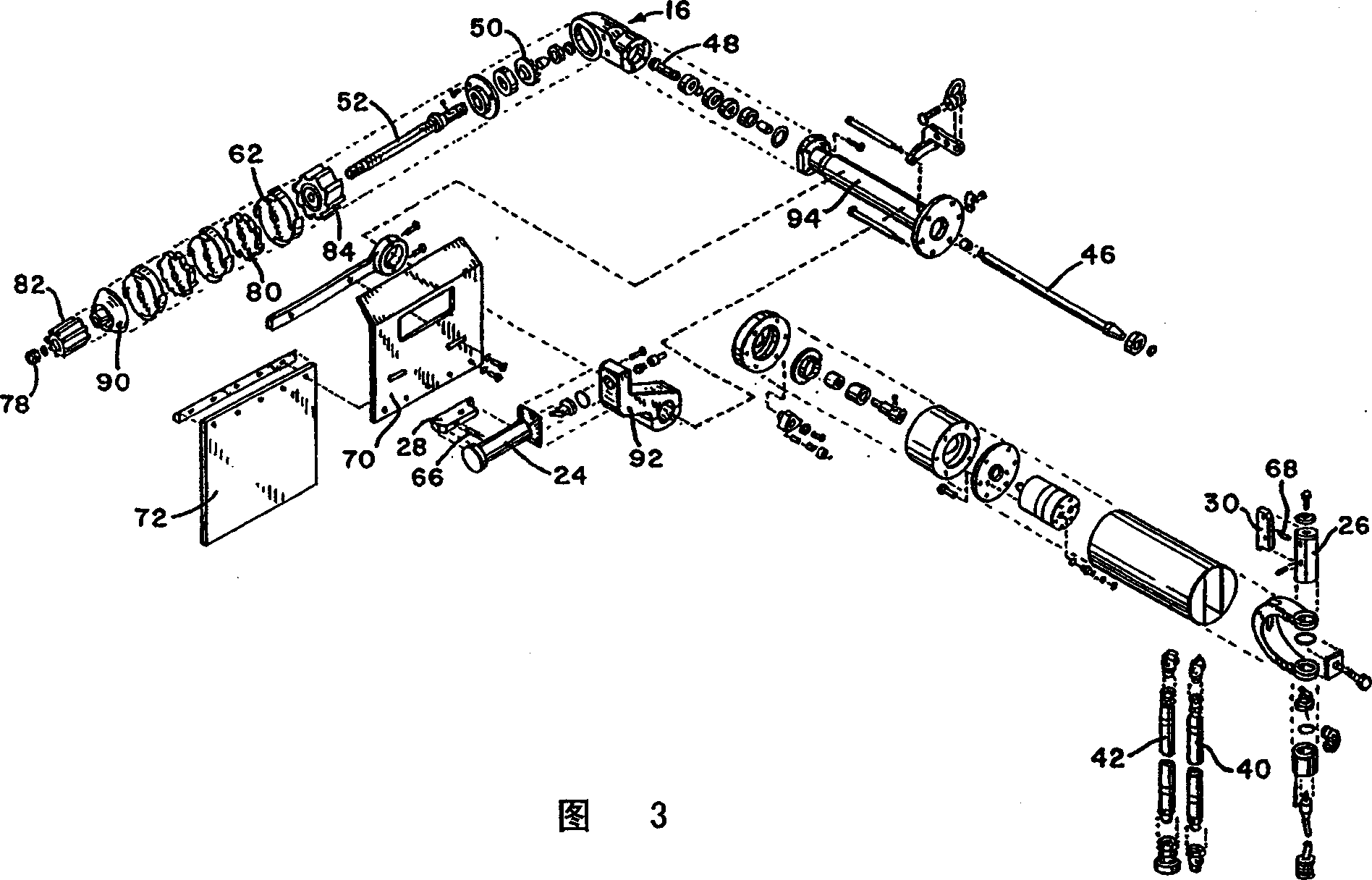

[0025] A preferred embodiment of the invention is described herein with reference to Figures 1-3 of the drawings, in which like reference numerals indicate like features of the invention.

[0026] Referring to FIG. 1, the degreasing tool of the present invention includes a main body 10 equipped with a reversible drive 12. As shown in FIG. The drive 12 preferably comprises a reversible hydraulic motor actuating a winding head 14 via a right angle gear unit 16 . When the motor is turned in one direction, the suet is wound onto the head 14, while reversing the motor causes the suet to unwind so that it can fall into a collection bin.

[0027] The weight of the tool is preferably suspended from suspension points 18 which can be moved by repositioning in holes 20,22 to adjust balance. The tool can be manually manipulated and positioned by grasping handles 24 and 26 . The front handle 24 is provided with a spring loaded actuator 28 and the rear handle 26 is provided with a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com