Metal toughening treatment system

A toughening treatment and metal technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of inconvenient use and complicated processing, and achieve the effect of improving accuracy, ensuring on-site safety, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

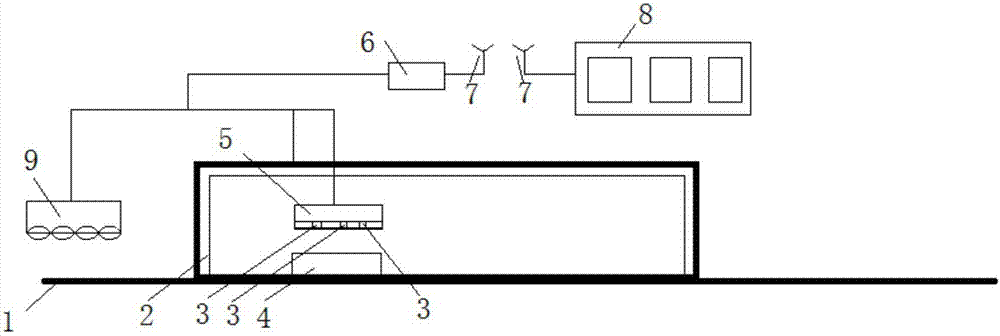

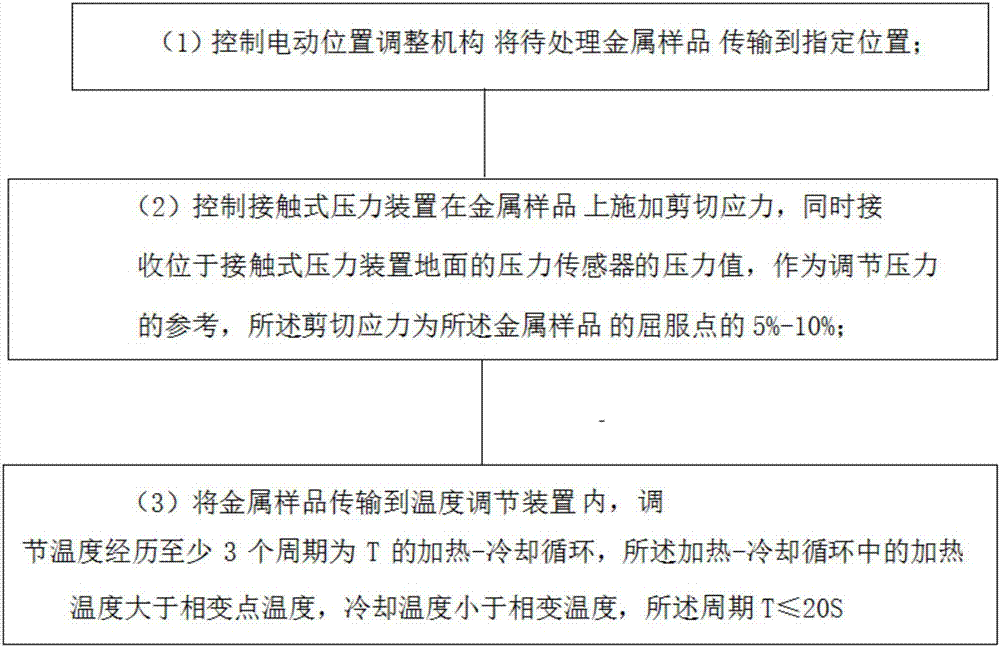

[0035] This implementation provides a metal toughening treatment system, such as figure 1 , the system includes a conveyor belt 1, a temperature adjustment device 2 located on the conveyor belt 1; the system also includes a contact pressure device 5, an electric position adjustment mechanism 9 connected with the contact pressure device 5, the temperature adjustment device 2 and The contact pressure device 5 is located at the same position; the control unit 6 connected with the temperature adjustment device 2, the contact pressure device 5 and the electric position adjustment mechanism 9; the remote server connected with the control unit 6 through the wireless communication unit 7 8. The contact pressure device 5 is provided with a pressure sensor 3 on the ground, and the pressure sensor 3 is used to collect the pressure value and feed it back to the control unit 6; the control unit 6 includes a first storage medium, a first processor, The first storage medium is used to store ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com