Garment Processing Method Based on Solvent and Physical Temperature Control

A technology of temperature control and processing method, which is applied in the field of garment processing and manufacturing, can solve the problems of large porosity, large production cost burden of enterprises, unfavorable separation and handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

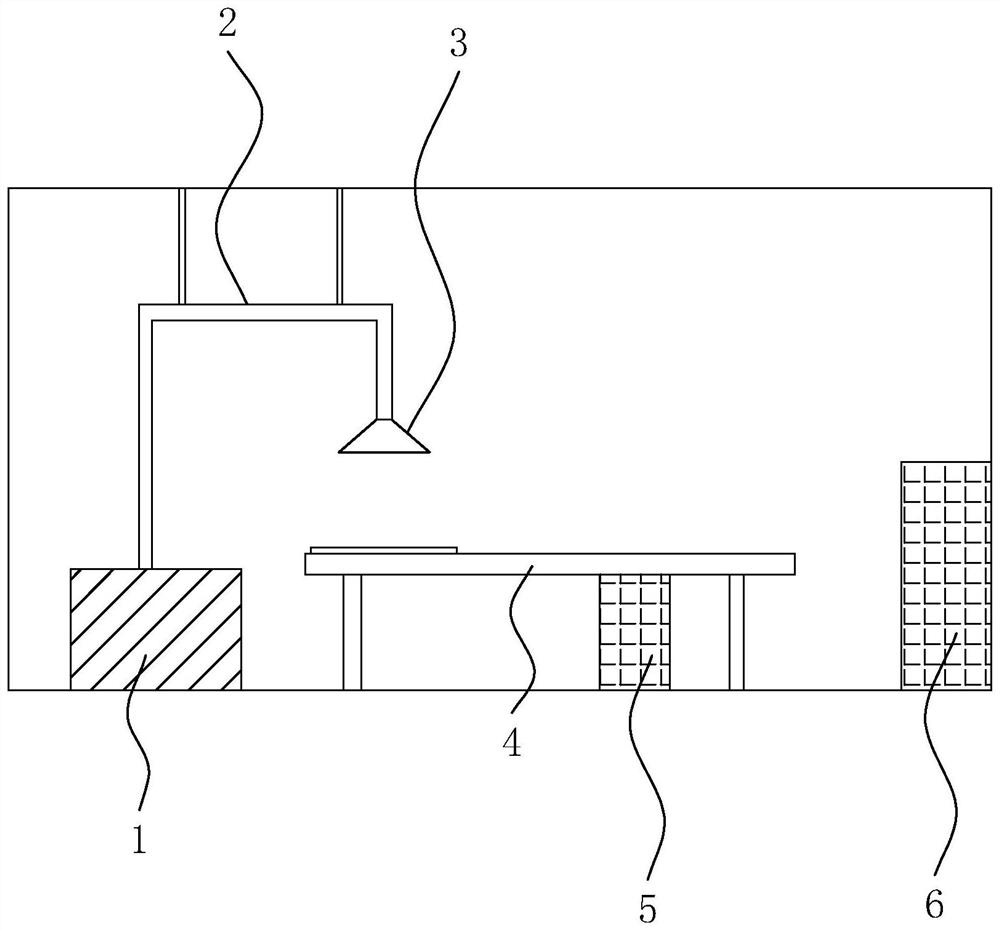

[0026] Embodiment 1: a kind of garment processing method based on solvent and physical temperature control, such as figure 1 As shown, it includes a solvent tank 1 for holding the coagulant, the solvent tank 1 is connected with a liquid suction pipe 2, the liquid suction pipe 2 is connected with an atomizing nozzle 3, and a device for placing a waiting A cooling platform for processing fabrics. The cooling platform includes a conveyor belt 4, a refrigerator 5 and an air conditioner 6.

[0027] During processing, the specific steps are as follows:

[0028] S1, prepare a coagulant and spray it evenly on the fabric to be processed. The coagulant used is an aqueous solution, and the aqueous solution needs to be filtered, and then placed in the solvent tank 1, and then the fabric to be processed is spread on the conveyor belt 4, and the atomizing nozzle 3 is started to spray the aqueous solution from the solvent tank 1 to On the fabric, the spraying speed after atomization is mai...

Embodiment 2

[0033] Embodiment 2: a kind of garment processing method based on solvent and physical temperature control, such as figure 1 As shown, it includes a solvent tank 1 for holding the coagulant, the solvent tank 1 is connected with a liquid suction pipe 2, the liquid suction pipe 2 is connected with an atomizing nozzle 3, and a device for placing a waiting A cooling platform for processing fabrics. The cooling platform includes a conveyor belt 4, a refrigerator 5 and an air conditioner 6.

[0034] During processing, the specific steps are as follows:

[0035] S1, prepare a coagulant and spray it evenly on the fabric to be processed. The coagulant used is composed of 1-butyl-3-methylimidazole chloride and aluminum chloride, and the mole fraction of aluminum chloride is 40% when the coagulant melts. When preparing the coagulant, first heat the solid 1-butyl-3-methylimidazole chloride to 80°C to make it completely melt into a liquid, then add aluminum chloride powder, stir well, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com