Control method of molding shape in glass base plate production

A control method and technology for glass substrates, applied in glass production, glass forming, glass forming, etc., can solve the problems of poor consistency of glass plates, high product loss rate, substrate explosion, etc., to improve cross-cutting stability, reduce Cutting loss rate, the effect of improving production output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

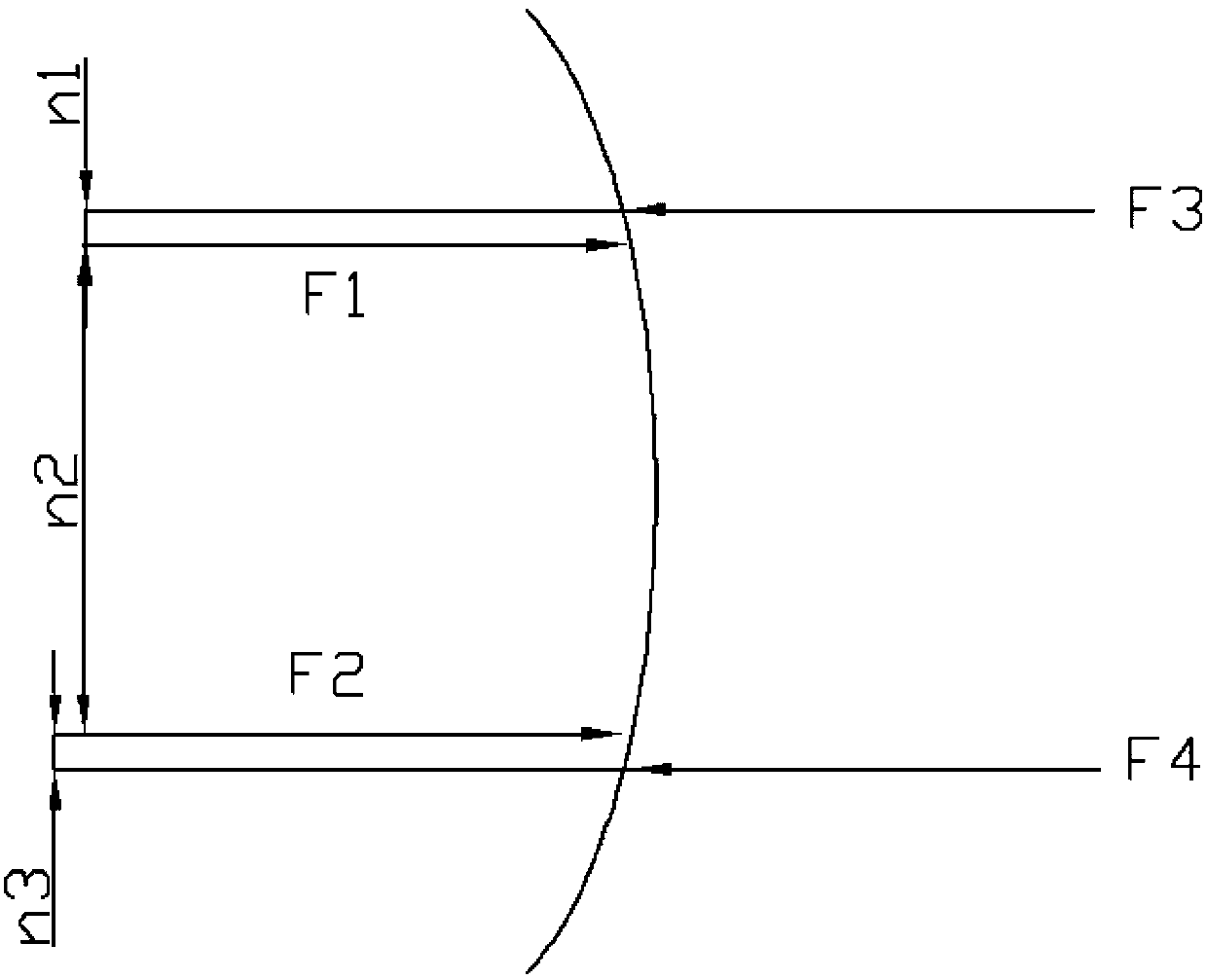

[0018] The first force F1 is 25N, the second force F2 is 30N, the third force F3 is 10N and the fourth force F4 is 1N, and the first force F1 is 1800mm away from the foundation ground, and the second force F2 is 1800mm away from the foundation ground. The base ground is 300mm, the third force F3 is 1820mm from the ground, and the fourth force F4 is 270mm from the base ground. By this method the glass substrate can be stabilized in a specific shape during the down-drawing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com