Injection molding rapid forming system

A fast, cavity-forming technology, used in grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of inconvenient manual gripping and grinding, difficult to detect the completion of grinding, and inconvenient to take out, etc., to achieve a simple structure. , Simple maintenance, the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

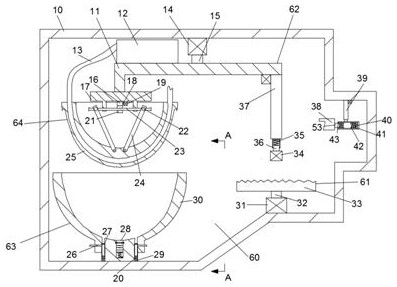

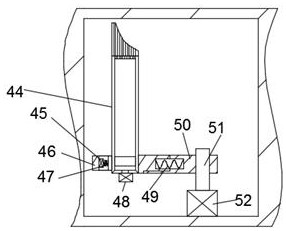

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0019] Such as Figure 1-Figure 4 , an injection molding rapid prototyping system according to an embodiment of the present invention, comprising a casing 10, the casing 10 is provided with a molding cavity 60 communicating with the outside world, and the casing 10 is provided with a starting mechanism 64, a coating mechanism 62 and a grinding mechanism 61, the grinding mechanism 61 can grind the formed material, and the smearing mechanism 62 can smear a release agent to the mould;

[0020] The starting mechanism 64 includes a thermal insulation mechanism 63 that can assist extrusion and facilitate demoulding. The upper end wall of the molding cavity 60 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com